Detection and repair device for fuel oil transportation drum

A technology for transporting barrels and fuel oil, which is used in measuring devices, transportation and packaging, injection devices, etc., can solve the problems of rust, the existence of fuel in oil barrels, and the inability to judge whether there are loopholes in oil barrels, so as to reduce the possibility of danger. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

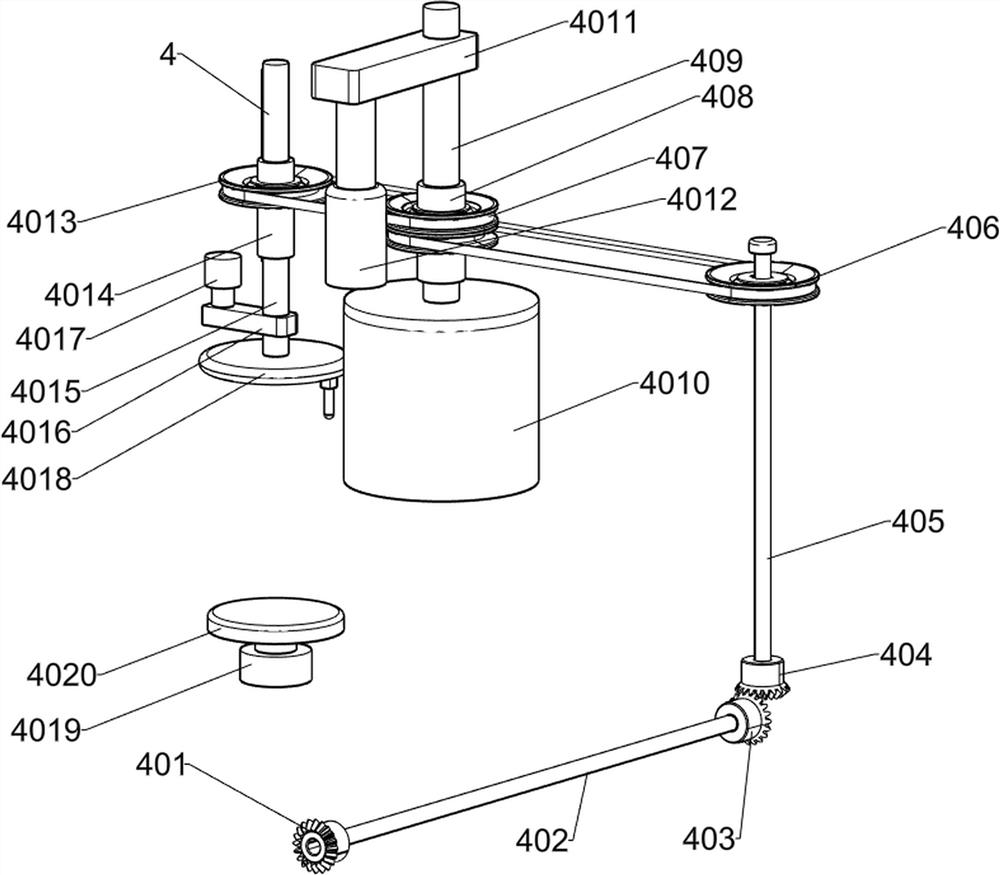

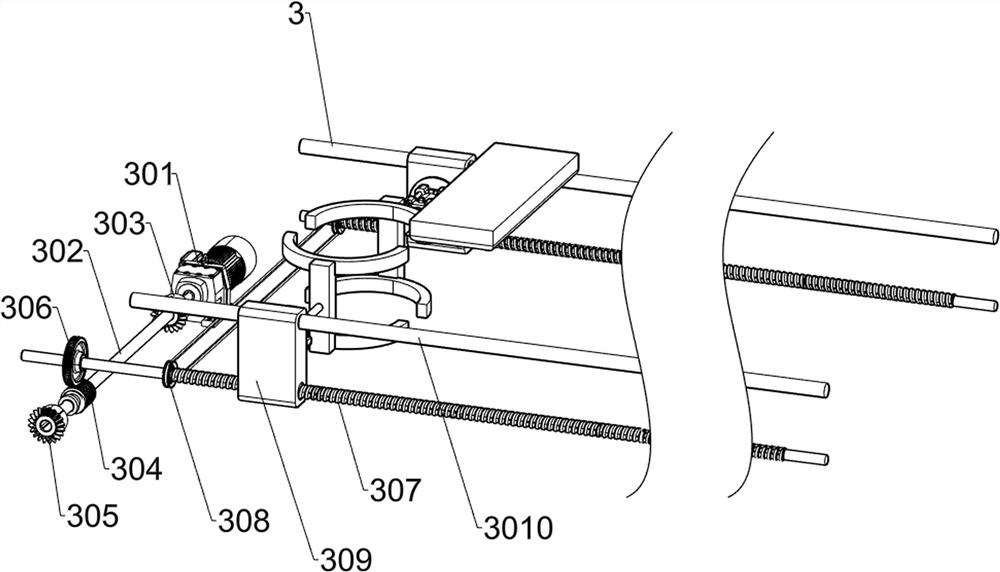

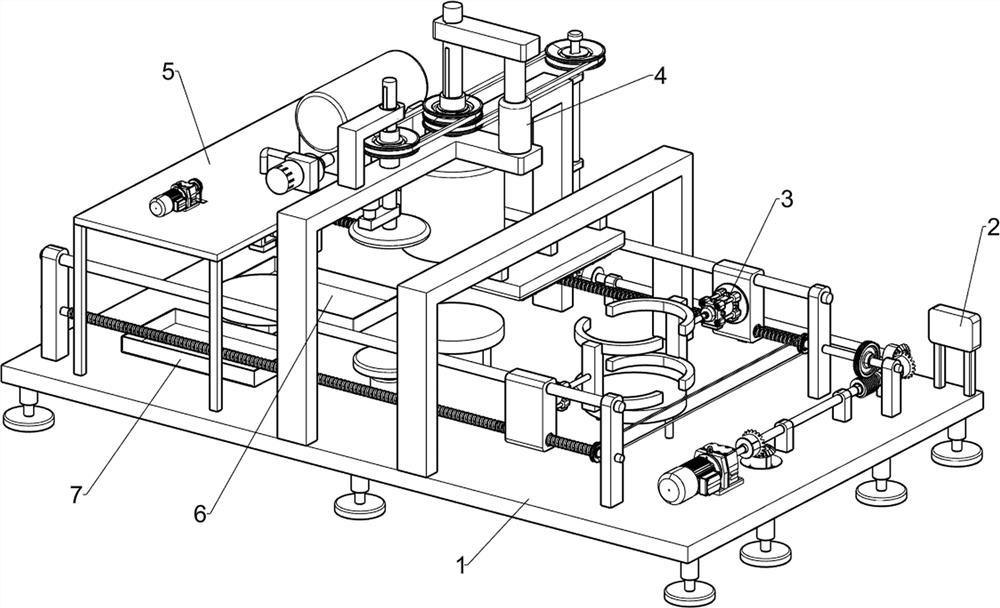

[0028] A detection and repairing device for a fuel tank, such as Figure 1-9 As shown, it includes a support chassis 1, a controller 2, a clamping and conveying detection system 3, a repair and rust removal system 4, a painting system 5, a first collection box 6 and a second collection box 7; the support chassis 1 and the controller 2 phases are connected; above the supporting chassis 1, a clamping and conveying detection system 3, a repairing and derusting system 4 and a painting system 5 are sequentially arranged; one end of the supporting chassis 1 is respectively connected with the first collection box 6 and the second collection box 7; The clamping and conveying detection system 3 is connected with the repairing and derusting system 4 ; the clamping and conveying detection system 3 is connected with the painting system 5 .

[0029] Working process: Before the device is in operation, transport the device to the working place, install and fix the whole device by fixing the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com