Cotton yarn with good tensile resistance

A technology of anti-stretching and cotton yarn, applied in the field of cotton yarn, can solve the problem that the anti-stretching performance of cotton yarn needs to be improved, and achieve the effect of good anti-stretching effect, increasing lightness and anti-stretching performance, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

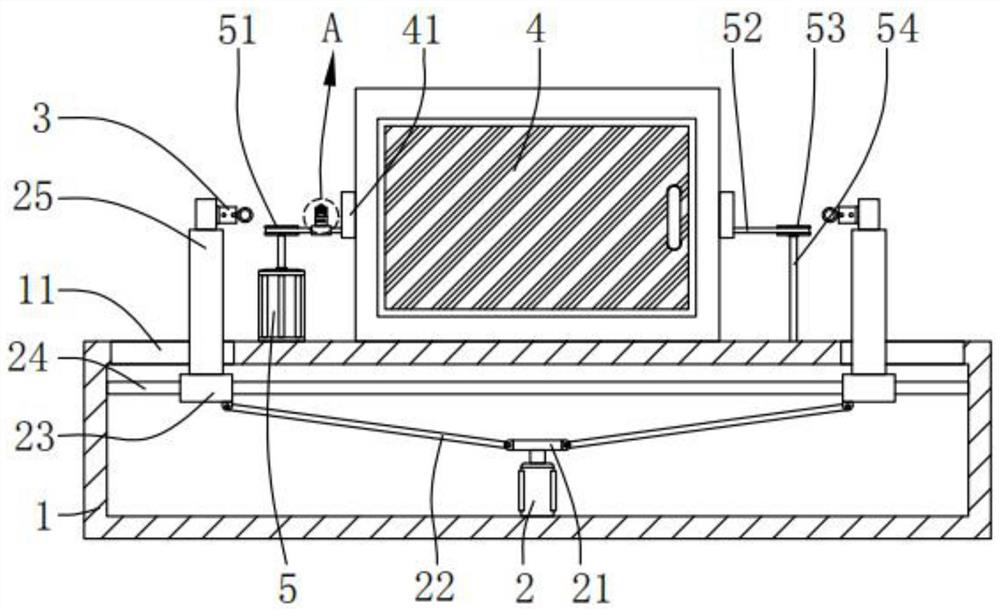

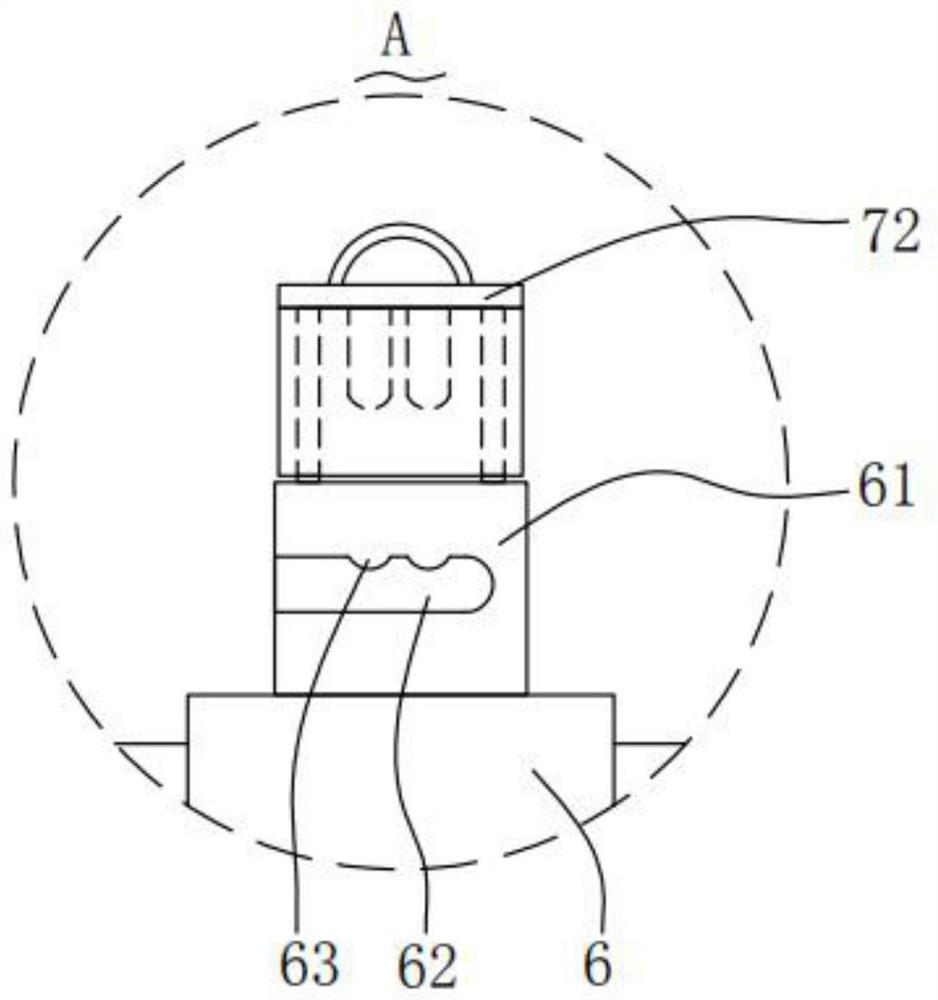

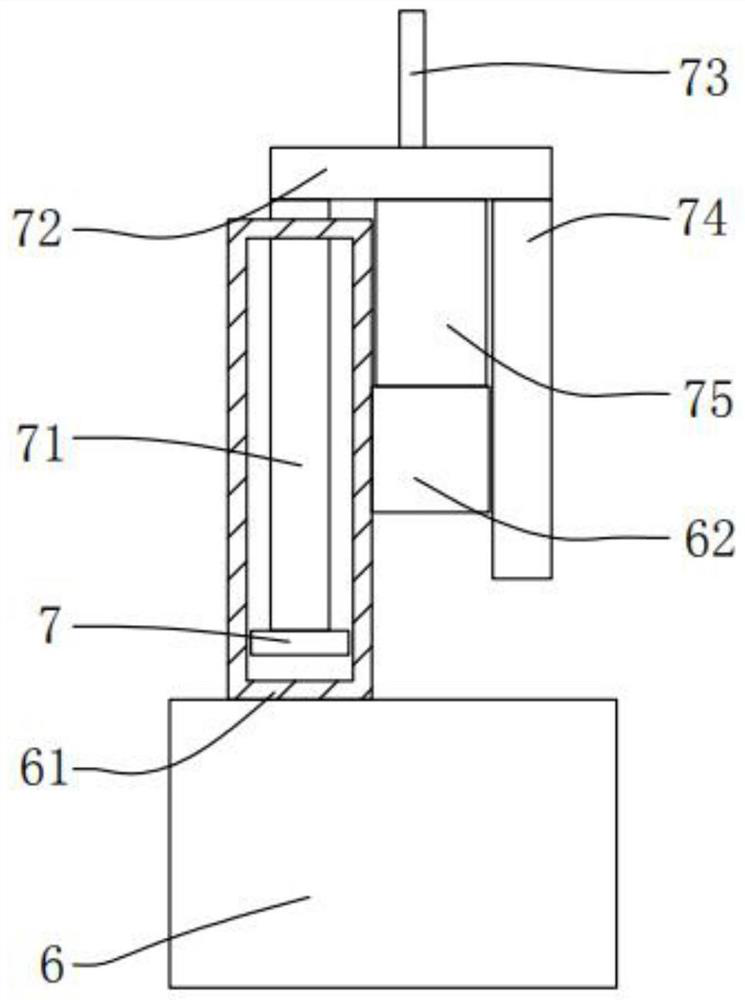

Image

Examples

no. 1 example

[0023] A cotton yarn with good tensile effect is composed of the following raw materials in parts by weight: 40 to 45 parts of cotton fiber, 8 to 15 parts of spandex fiber, 15 to 20 parts of polyester medium and long fiber, and 1 to 2 parts of glass fiber 0.2-1 part of viscose medium long fiber, 1.5-3 parts of graphene, 4-8 parts of polypropylene, 1-2 parts of glycerol stearate.

[0024] Spandex fibers are added to the cotton fiber grinding wheel process for blending to increase the stretch resistance of the cotton yarns after molding, thereby improving the stability of the cotton yarns after molding. Glass fibers are added during the blending of spandex fibers and cotton fibers to further increase cotton yarns. The lightness and tensile properties of cotton yarns can improve the tensile properties of cotton yarns after molding, and the tensile effects are better than traditional cotton yarns.

[0025] The use of spandex fiber can effectively improve the anti-oxidation and oil...

no. 2 example

[0027] Preferably, the cotton yarn with good stretch resistance effect is composed of the following raw materials in parts by weight: 42 parts of cotton fiber, 15 parts of spandex fiber, 18 parts of polyester medium and long fiber, 1.8 parts of glass fiber, 0.7 part of viscose medium and long fiber, 2.5 parts of graphene, 6.5 parts of polypropylene, 1.5 parts of glycerol stearate.

no. 3 example

[0029] Preferably, the cotton yarn with good stretch resistance effect is composed of the following raw materials in parts by weight: 40 parts of cotton fiber, 12 parts of spandex fiber, 16 parts of polyester medium and long fiber, 1.2 parts of glass fiber, 0.3 part of viscose medium and long fiber, 1.8 parts of graphene, 5 parts of polypropylene, 1 part of glycerol stearate.

[0030] Compared with related technologies, the cotton yarn with good tensile effect provided by the present invention has the following beneficial effects:

[0031] Spandex fibers are added to the cotton fiber grinding wheel process for blending to increase the stretch resistance of the cotton yarns after molding, thereby improving the stability of the cotton yarns after molding. Glass fibers are added during the blending of spandex fibers and cotton fibers to further increase cotton yarns. The lightness and tensile properties of cotton yarns can improve the tensile properties of cotton yarns after mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com