Fabricated shear wall combining concrete-filled steel tube and double-sided composite wall

A technology of steel pipe concrete and laminated shear walls, which is applied in the direction of walls, buildings, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

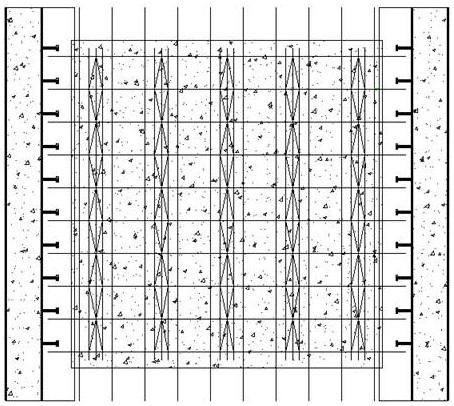

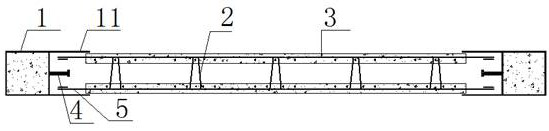

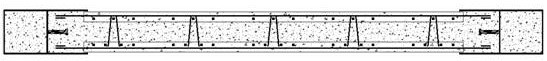

[0022] Such as Figure 1-3 , the two sides of the laminated shear wall use square steel pipe 1 as the restraining member, weld two parallel steel plates on one side of the square steel pipe 1 as the guard plate 11, and the side of the square steel pipe 1 and the two guard plates 11 form a mounting groove A row of studs 4 is welded between the two guard plates 11 along the side of the square steel pipe 1, and the two ends of the laminated shear wall are inserted into the installation groove. The combined shear wall panel construction method shortens the length of the horizontal wall distributed steel bars protruding from the leaf plate (not less than 0.6 times the minimum anchorage length of the steel bars), and sets mechanical anchor joints at the ends to superimpose the two sides of the shear wall. There are transverse steel bars 5 stretching out at the ends, and there are mechanical anchor joints at the ends of the transverse steel bars 5. In this implementation, a small sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com