Novel water distributor adjusting structure

A technology for regulating structure and water distributor, applied in wellbore/well components, production fluid, sealing/packing, etc., can solve the problems of limited function, complex regulating structure and large volume, etc., to achieve compact design, small volume, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

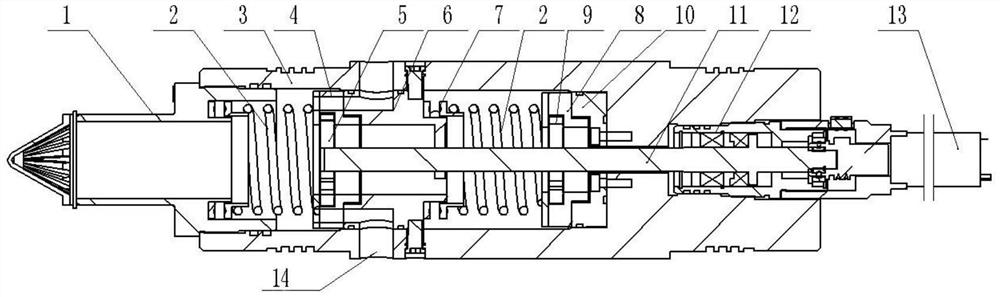

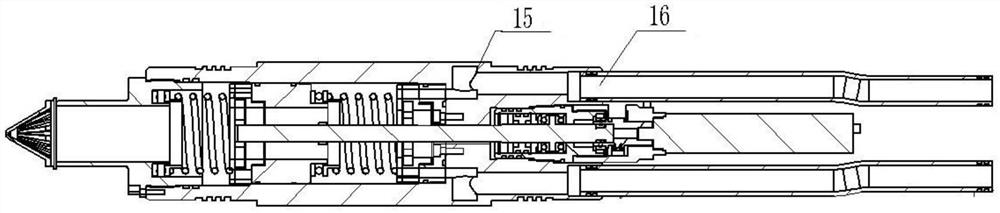

[0036] Such as Figure 1-5 As shown, a new type of water distributor adjustment structure includes a fairing 1, a compression spring 2, a main body 3, a rotary vane, a rotating core, a fixed cylinder, a decompression bearing 7, a main shaft 11, a dynamic seal 12, a motor assembly 13 and a lower One deck of aqueduct 16.

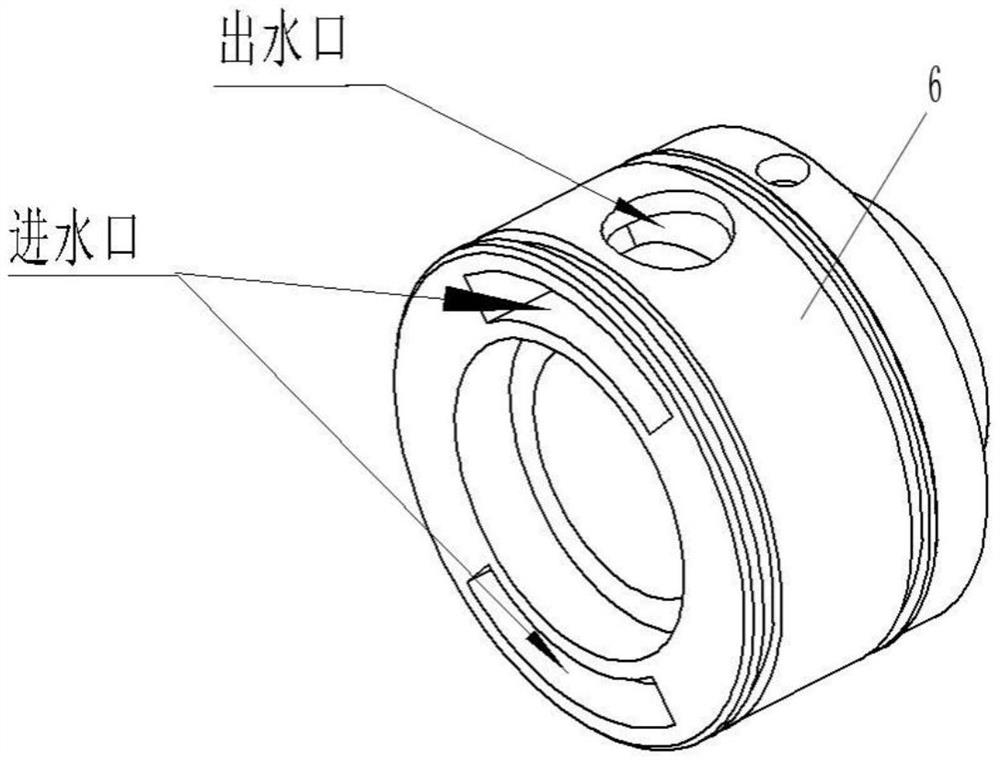

[0037] The body 3 has internal passages for the circulation of the injection water. There are at least two fixed barrels in the internal channel of the main body 3, and the fixed barrels form a seal with the main body through an O-ring to realize layered isolation and prevent water injection from layering. The fixed cylinder is provided with a central channel and a water injection channel, the central channel is used for water flow into the rear of the inner channel, the water injection channel is used for water flow into the opposite water injection port, and the water injection port is set on the main body 3 for water flow into in the oil layer.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com