A self-powered dynamic weighing device and working method based on magnetostrictive material

A magnetostrictive material and dynamic weighing technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, measuring devices, electromechanical devices, etc., can solve the problem of large equipment footprint, cumbersome installation, and road excavation Large area and other problems, to achieve the effect of simple installation, high sensitivity and small structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

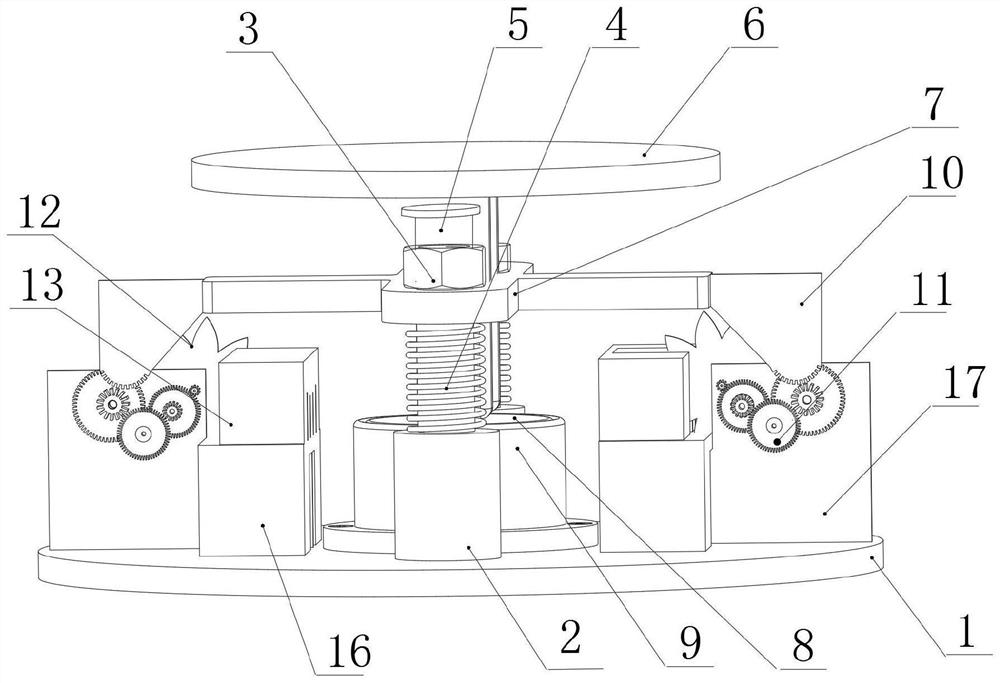

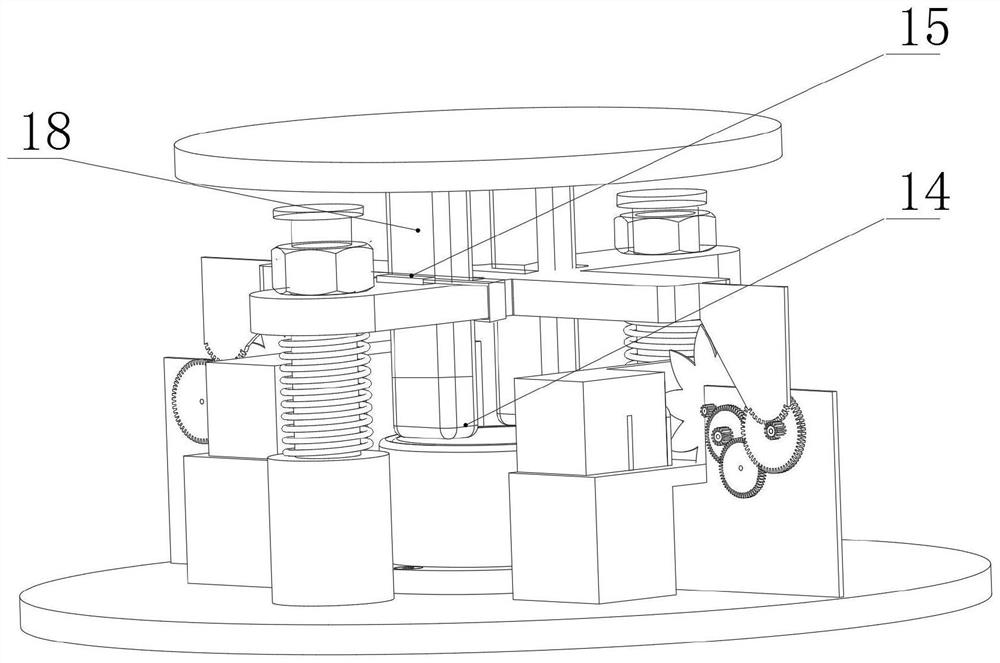

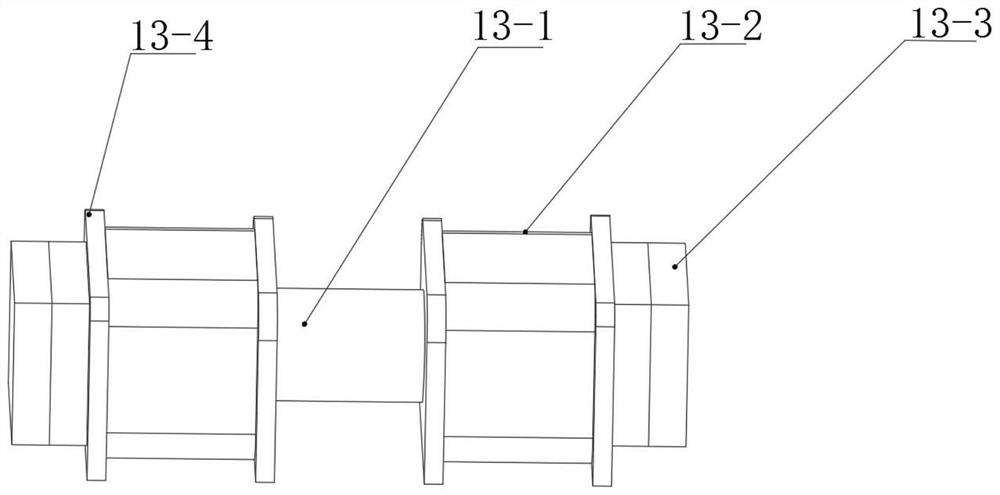

[0032] Such as figure 1 and 2 As shown, a piezoelectric dynamic weighing device based on magnetostrictive materials includes a base 1, a support plate 6, a load-bearing column 18, a guide assembly, a weighing assembly and a self-powered assembly. Bearing column 18 adopts polymer nylon rubber. The weighing assembly includes a piezoelectric sensor 8 and a piezoelectric sheet holder 9 . Bolt holes are drilled on the ears extending from the bottom of the piezoelectric sheet holder 9, and the center position of the piezoelectric sheet holder 9 and the top surface of the base 1 is fixed with bolts. The top of the piezoelectric sheet holder 9 is provided with a sensor installation groove. A piezoelectric sensor 8 with a detection surface facing up is installed in the sensor installation groove. The piezoelectric sensor 8 includes four piezoelectric sheets connected in series; the signal output line of the piezoelectric sensor 8 is connected to the signal processing module. The s...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that: the side of the blade of the impeller 12 is parallel to the axis of the impeller 12, so that the blade is easier to bend after touching the magnetostrictive rod 13-1, reducing capacity loss.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that the final output gear is connected to the output shaft through a one-way bearing; so that the final output gear can only drive the output shaft to rotate in one direction, thereby avoiding the Output rotating shaft and impeller 12 continue to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com