A night vision compatible filter with high and low temperature resistance and high visible light transmission and preparation method

A night vision compatible, high and low temperature resistant technology, applied in the direction of filters, optics, optical components, etc., can solve the problems of high visible light transmittance, can not take into account the high and low temperature environment, etc., to achieve good cut-off performance, excellent performance, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of a night vision compatible filter with high and low temperature resistance and high visible light transmission, comprising the following steps:

[0032] S1: Weigh the near-infrared absorber, the organic solvent and the transparent host resin in parts by mass of 0.1-0.5, 60-80 and 40-50, mix them evenly, and place them in a glassware for 24 hours. After the organic solvent is completely volatilized Transfer to a 100°C oven for complete drying for 1 hour, then heat treatment at 120°C and hot-press molding to obtain a near-infrared absorption layer with a thickness of 0.5-1 mm;

[0033] S2: weigh polymethyl methacrylate, dodecyltrimethoxysilane, Hexafluorobutyl methacrylate, ethyl orthosilicate, lanthanum stearate, stearic acid, and nano-titanium dioxide were mixed uniformly and added to the reaction vessel, heated to 60-100°C, and stirred for 2.0-4.0 h. Cooling to get anti-reflection protective coating;

[0034]...

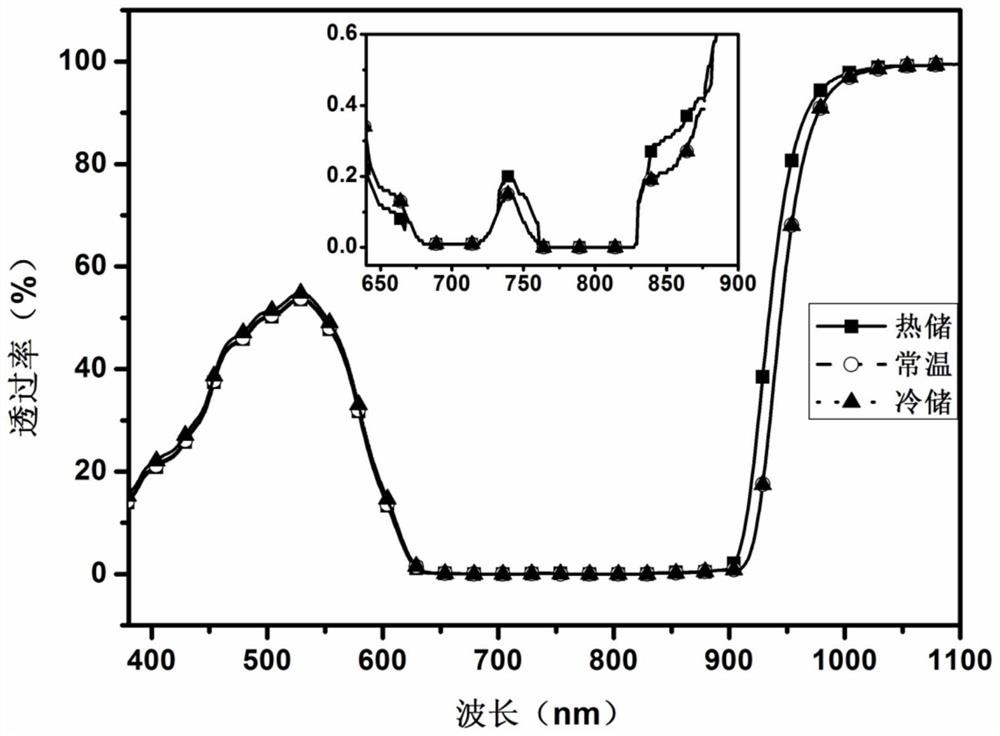

Embodiment 1

[0055] This embodiment provides a night vision compatible filter that is resistant to high and low temperatures and has high visible light transmission. The night vision compatible filter is a layered structure, including a near-infrared absorption layer and an antireflection coating layer. The film layer is attached to one side of the near-infrared absorption layer; the thickness of the anti-reflection film layer is 60 μm, and the thickness of the near-infrared absorption layer is 1.0 mm; the expansion coefficients of the near-infrared absorption layer and the anti-reflection film layer are the same , the refractive index is different.

[0056] The present embodiment also provides a method for preparing a night vision compatible filter with high and low temperature resistance and high visible light transmission as described above, comprising the following steps:

[0057] (1) to (4) are the same as Comparative Example 1;

[0058] (5) adopting 120 ℃ of heat treatment for the n...

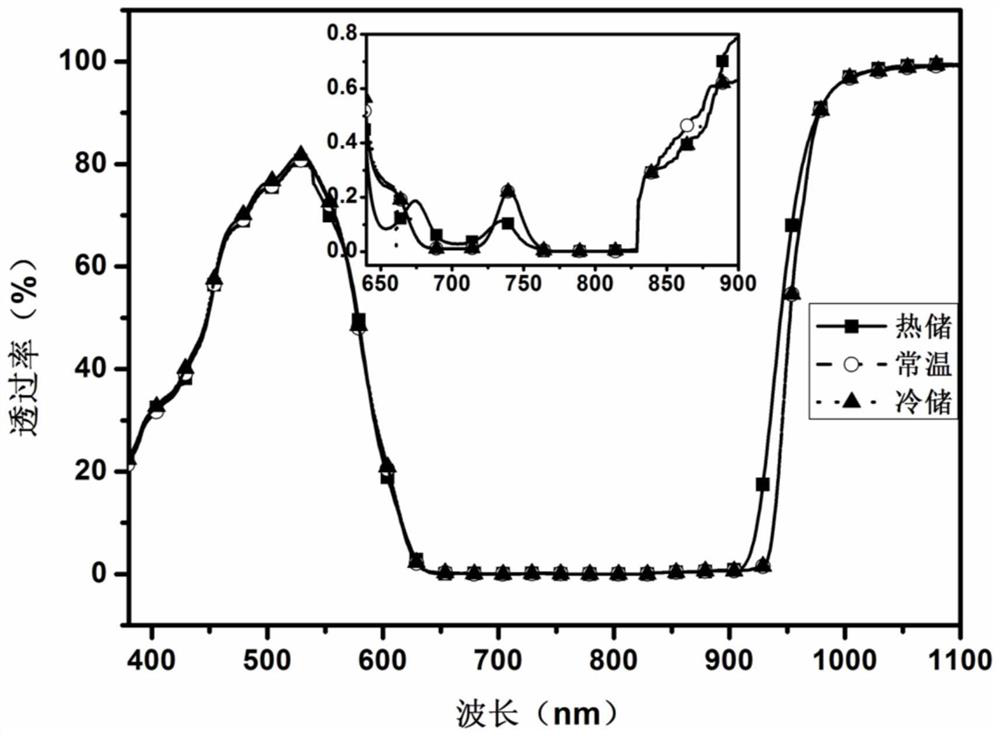

Embodiment 2

[0065] This embodiment provides a night vision compatible filter that is resistant to high and low temperatures and has high visible light transmission. The night vision compatible filter is a layered structure, including a near-infrared absorption layer and an antireflection coating layer. The film layer is attached to one side of the near-infrared absorption layer; the thickness of the anti-reflection film layer is 60 μm, and the thickness of the near-infrared absorption layer is 1 mm; the expansion coefficients of the near-infrared absorption layer and the anti-reflection film layer are the same, The refractive index is different.

[0066] The present embodiment also provides a method for preparing a night vision compatible filter with high and low temperature resistance and high visible light transmission as described above, comprising the following steps:

[0067] (1) with embodiment 1;

[0068] (2) Weigh the near-infrared absorber, chloroform and polymethyl methacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com