PTC thermistor ceramic material as well as preparation method and application thereof

A technology of thermistors and ceramic materials, applied in the direction of resistance manufacturing, heating element materials, resistors, etc., can solve the problems of reduced calorific value, lower working temperature, and lower heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

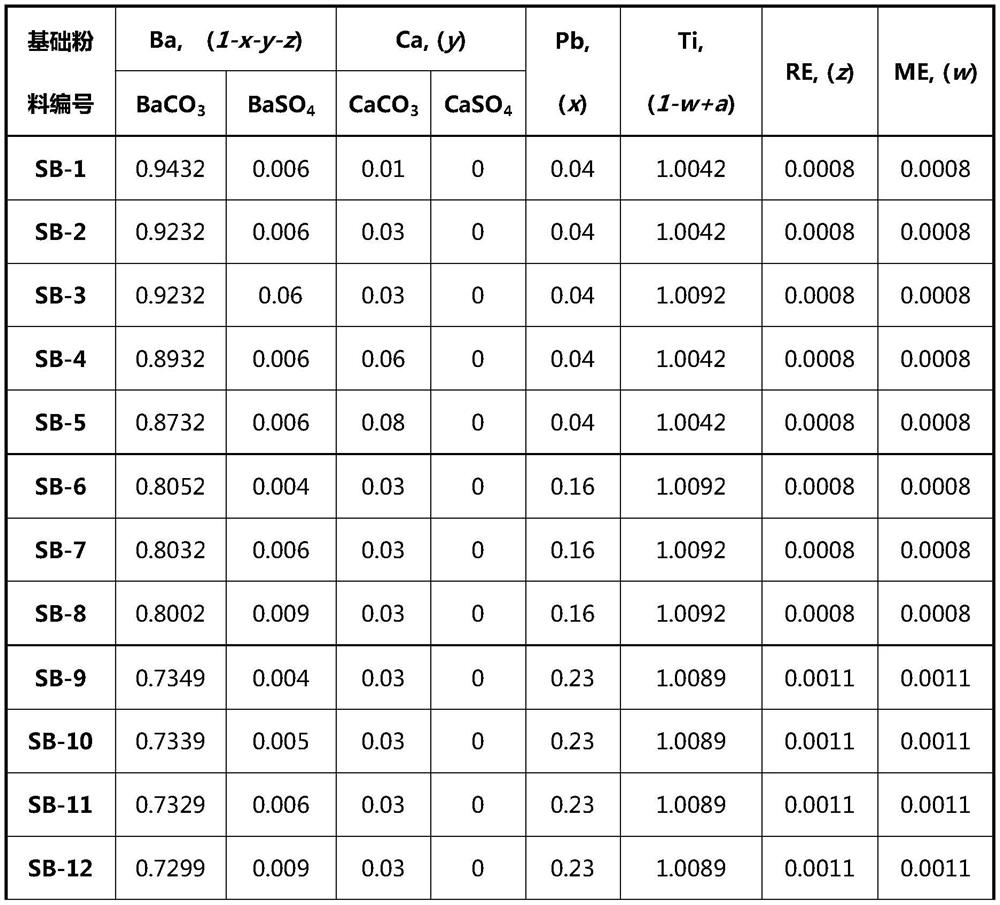

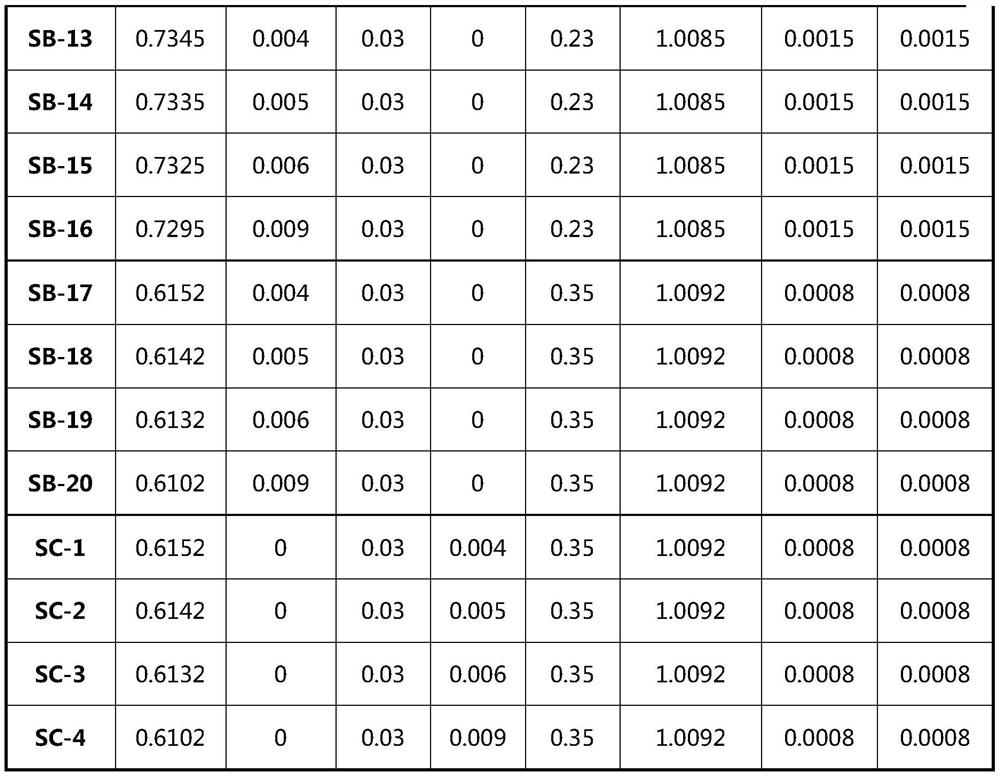

Embodiment 1

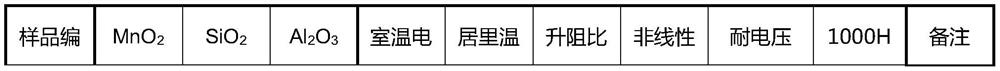

[0063] After preparing the SB series basic ceramic powder (synthetic material), weigh the SiO 2 ,Al 2 o 3 ,MnO 2 , mixed by ball milling in deionized water, then dried and added with a binder to granulate, and pressed at a pressure of 10MPa to make a square green body with a size of 24×15×2.9mm. In an air atmosphere, the pressed square element The billet is sintered at a temperature of 1280-1330 ° C for 30 minutes, so that the square green billet is fully sintered and the solid phase reaction is realized. The surface of the ceramic obtained after sintering is ground to keep the thickness at 2.4mm, and then coated on the surface of the ceramic sheet Ag and Zn electrode paste, and fired at 480-520 ° C, heat preservation for 8 minutes, solidified the electrode, finally obtained PTC thermistor ceramic sheet 1, and tested its performance, the performance of PTC thermistor ceramic sheet 1 is shown in the table 2.

[0064] The results of Example 1 are shown in Table 2.

[0065] ...

Embodiment 2

[0073] After preparing the SB series basic ceramic powder (synthetic material), weigh the SiO 2 ,Al 2 o 3 ,MnO 2 ,MnCO 3 , mixed by ball milling in deionized water, then dried, added with a binder, granulated, and pressed at a pressure of 10 MPa to make a square green body with a size of 24×15×2.9 mm. In the air atmosphere, the pressed square green body is sintered at 1270-1310° C. for 30 minutes, so that the square green body is fully sintered and solid-state reaction is realized. Grind the ceramic surface obtained after sintering to keep the thickness at 2.4 mm, then coat Ag and Zn electrode paste on the surface of the ceramic sheet, and fire at 480-520 ° C for 8 minutes to solidify the electrode, and finally The PTC thermistor ceramic sheet 2 was obtained, and its performance was tested. The performance of the PTC thermistor ceramic sheet 2 is shown in Table 3.

[0074] The results of Example 2 are shown in Table 3.

[0075] Table 3: Sample composition and performance...

Embodiment 3

[0082] After preparing the SB series basic ceramic powder (synthetic material), weigh the SiO 2 ,Al 2 o 3 ,MnCO 3, mixed by ball milling in deionized water, then dried, added with a binder, granulated, and pressed at a pressure of 10 MPa to make a square green body with a size of 24×15×2.9 mm. In the air atmosphere, the pressed square green body is sintered at 1240-1290° C. for 30 minutes, so that the square green body is fully sintered and solid-state reaction is realized. Grind the ceramic surface obtained after sintering to keep the thickness at 2.4 mm, then coat Ag and Zn electrode paste on the surface of the ceramic sheet, and fire at 480-520 ° C for 8 minutes to solidify the electrode, and finally The PTC thermistor ceramic sheet 3 was obtained, and its performance was tested. The performance of the PTC thermistor ceramic sheet 3 is shown in Table 3.

[0083] The results of Example 3 are shown in Table 4.

[0084] Table 4: Sample composition and performance list of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap