Waste aluminum treatment equipment

A technology for processing equipment and equipment racks, applied in the direction of improving process efficiency, etc., can solve the problems of difficult design collection and processing, low operation efficiency, etc., and achieve the effects of low energy consumption, high pressing efficiency, and enlarged collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

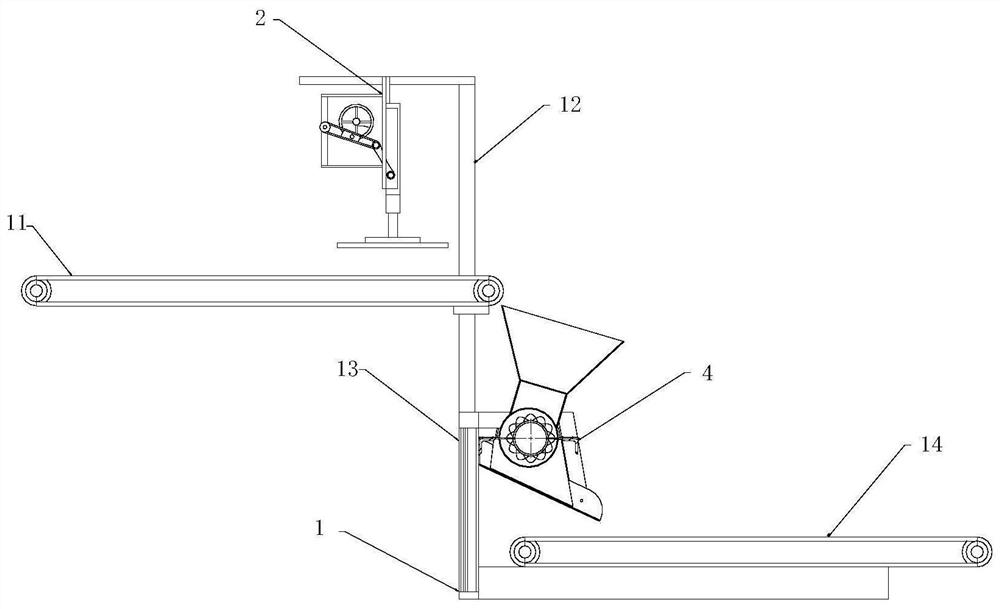

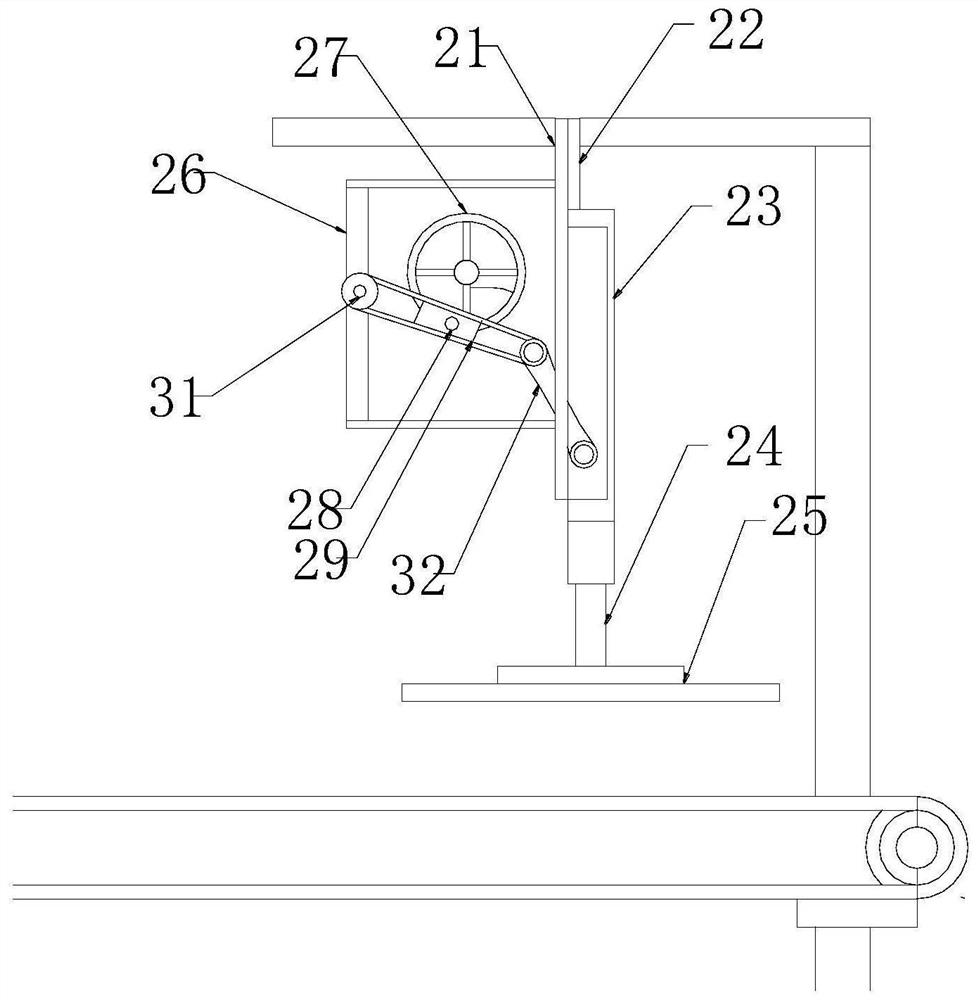

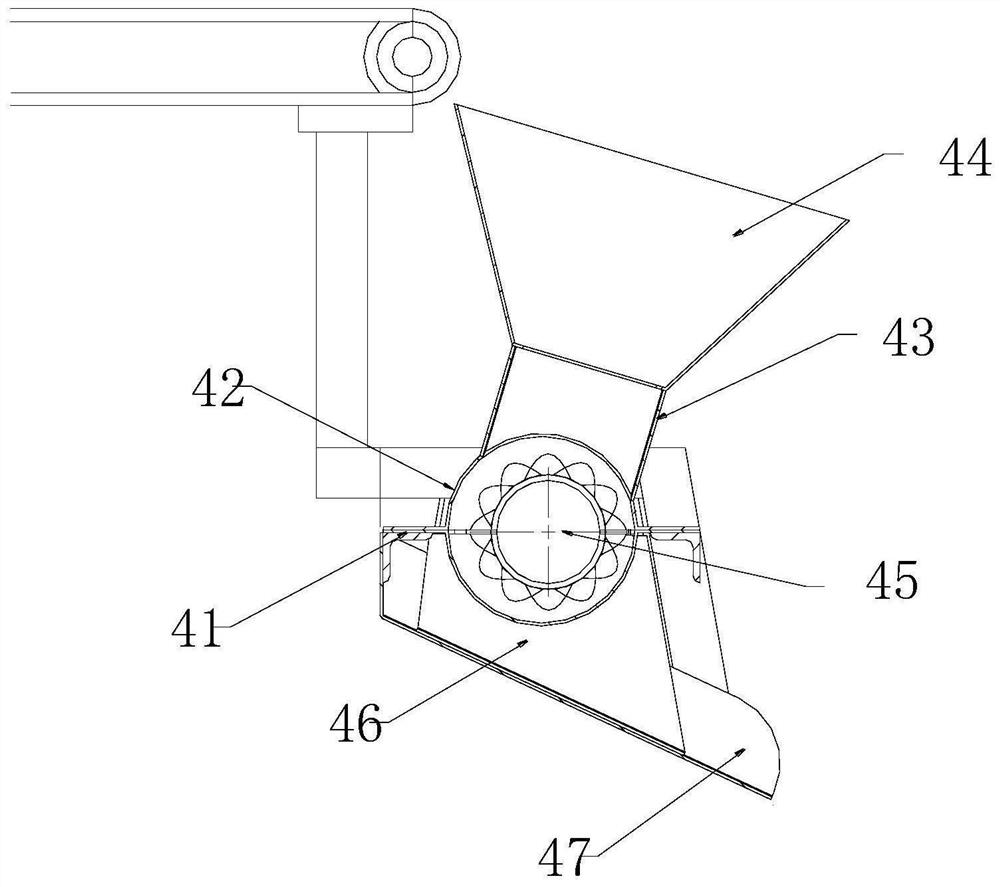

[0024] see Figure 1~3 , a kind of scrap aluminum treatment equipment, comprises frame 1, and described frame 1 is provided with feeding conveyer belt 11 and discharging conveying belt 14, and between described feeding conveying belt 11 and discharging conveying belt 14 is respectively arranged There are an upper equipment rack 12 and a lower equipment rack 13, the upper equipment rack 12 is provided with a primary pressing device 2, and the primary pressing device 2 is provided with a vertical frame 21, the vertical frame 21 is provided with a vertical rail 22, a movable slider 23 is installed on the vertical rail 22, a straight rod 24 is installed on the bottom end of the movable slider 23, and an extrusion plate 25, the extruding plate 25 is located directly above the belt surface of the feeding conveyor belt 11, a transmission frame 26 is arranged on the side of the vertical frame 21, and a transmission disc 27 is installed on the transmission frame 26, and the The disk s...

Embodiment 2

[0028] see image 3 and Figure 4 , this embodiment serves as a further optimization of the first embodiment, on the basis of which, the main body of the extrusion roller 45 is a roller 48, and several extrusion ribs 49 are provided on the sides of the roller 48 in a staggered manner. The installation position of the extrusion roller 45 deviates from the centerline of the extrusion barrel 42, so that one side of the extrusion roller 45 fits the inner wall of the extrusion barrel 42, and the other side of the extrusion roller 45 is in contact with the extrusion material. There is a gap in the inner wall of the barrel 42 . In the present application, there is a gap between the extruding roller 45 and one side of the extruding barrel 42, thereby avoiding the problem of material slipping from both sides and ensuring the adequacy of extruding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com