Cutting smoke dust collecting and treating system

A technology of dust collection and treatment system, which is applied in the direction of dust removal, metal processing machinery parts, maintenance and safety accessories, etc., which can solve the lack of dust treatment devices and systems, affect the air quality of the cutting workshop, and the dust cannot be effectively treated, etc. problems, to achieve the effect of easy promotion and utilization, easy assembly and disassembly, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

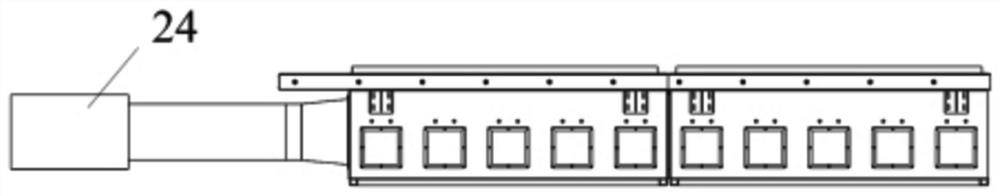

[0031] The frame is provided with several cutting platform units and the collection and processing units corresponding to the cutting platform units one by one. The smoke and dust collection compartments are connected, one side of the frame is equipped with a suction purification device, and a damper partition is installed between the smoke dust collection cabin and the collection and processing unit. After the damper partition is closed, a draft is formed between the collection and processing unit and the suction and purification device. The channel reduces the space for dust collection, improves the efficiency of dust collection and treatment, and reduces the pollution of dust to the cutting workshop; one side of the frame is equipped with a cutting machine walking track, which is the guide rail for the cutting machine to travel when cutting materials.

[0032] Specifically, there are several parallel and equidistant transverse partitions arranged in the frame, and a soot col...

Embodiment 2

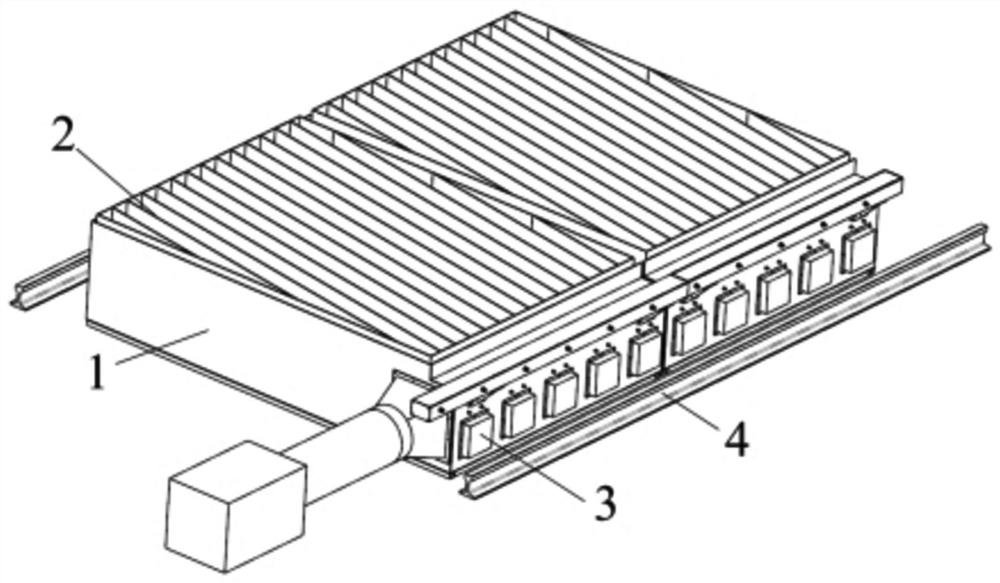

[0037] A cutting dust collection and treatment system according to the present invention comprises a cutting platform unit 2, a dust collection and treatment system unit 3, and a frame 1 supporting the cutting platform unit and the dust collection and treatment system unit.

[0038] The cutting fume collection and processing system is composed of several identical cutting platform units 2 , the same number of cutting platform units as the number of fume collection and processing system units 3 and a frame 1 .

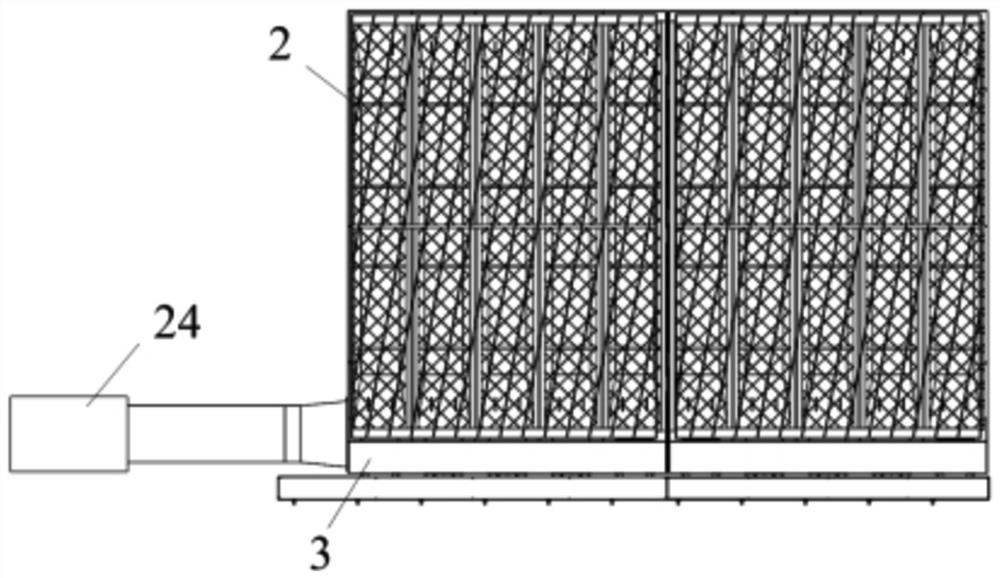

[0039] When the cutting machine gun head was cutting operation above a certain cutting platform unit 2, the suction and purification device 24 of the dust collection and processing system unit 3 was in an open state, and the sensor 21 on the rectangular steel pipe 22 sensed the position of the cutting machine gun head, and The signal is fed back to the cylinder controller, which controls the expansion and contraction of the cylinder 19 by controlling the air pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com