Rapid drilling system and drilling process for concrete deep crack detection

A technology for deep cracks and concrete, which is applied in the field of rapid drilling system and drilling technology for deep crack detection in concrete. It can solve problems such as harmful health, large dust, and inability to adjust the angle of the drill bit, and achieve the effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

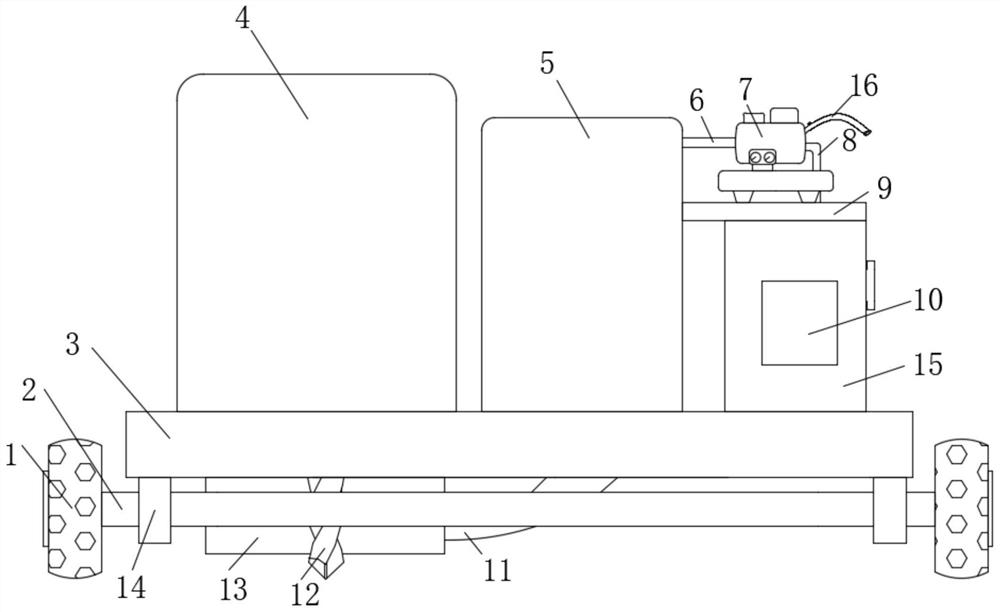

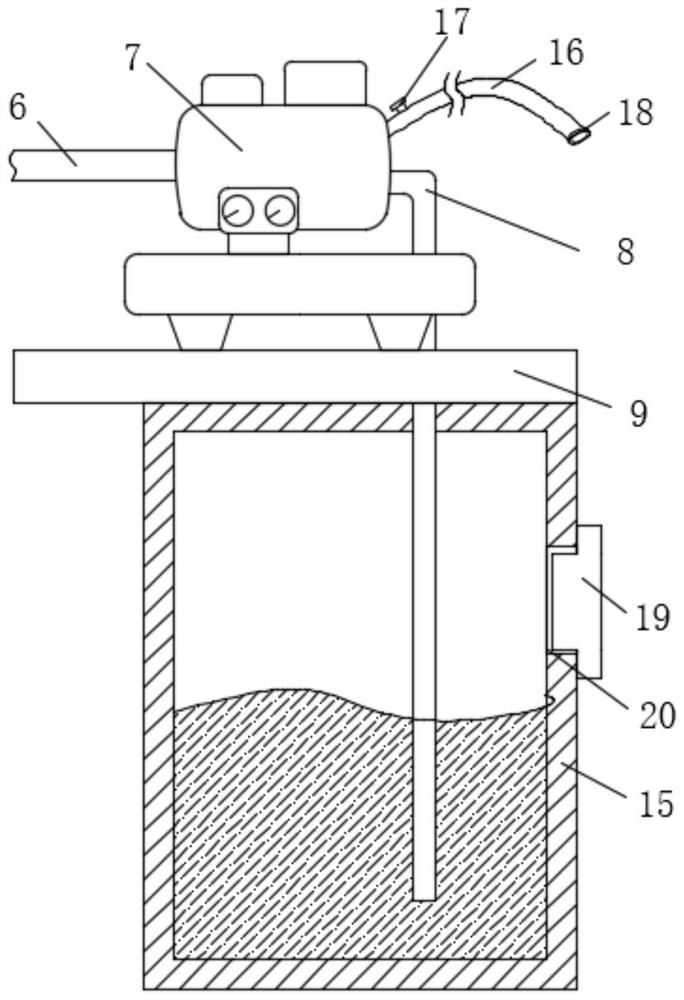

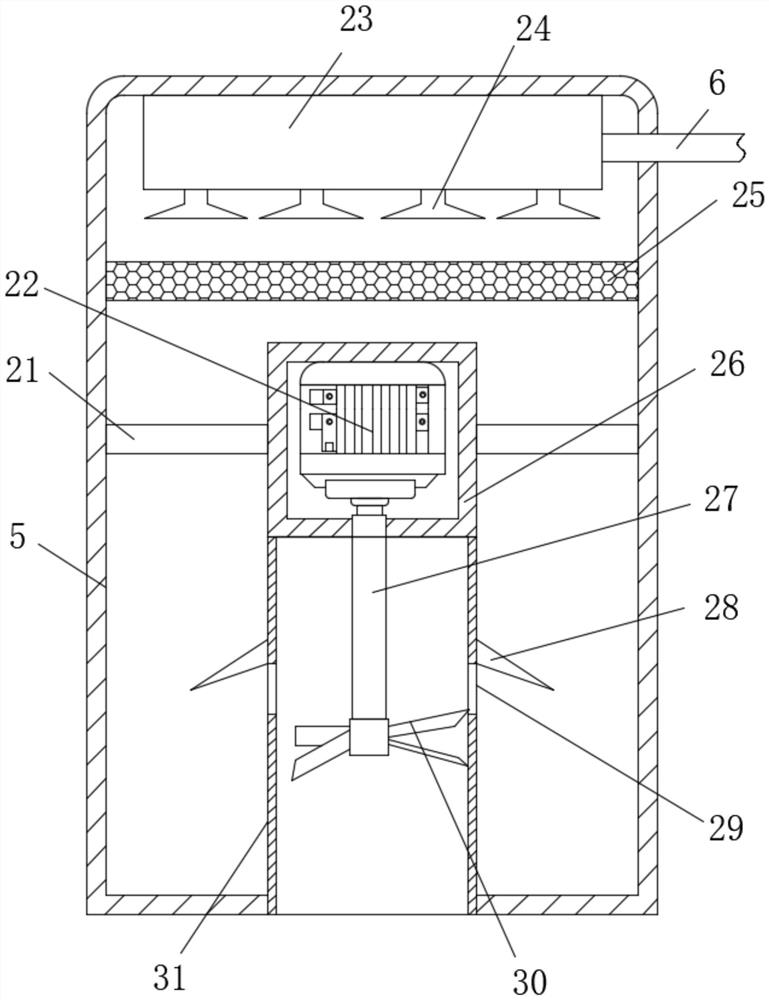

[0047] Embodiment one: if Figure 1-3 , 5-15, a rapid drilling system for detecting deep cracks in concrete, including a base plate 3, the top of the base plate 3 is fixedly connected with a rectangular box 4, a dust collection box 5 and a water tank 15, and the bottom of the base plate 3 is fixedly connected with two Two symmetrical four support blocks 14, the inside of the two support blocks 14 on the same side are connected to the same rotating shaft 2, the two ends of the rotating shaft 2 are fixedly connected to the wheels 1, and the bottom of the base plate 3 is provided with a ring for preventing dust from getting out. The inside of the rectangular box 4 is provided with an adjustment assembly for adjusting the drilling angle, the inside of the rectangular box 4 is provided with a drilling assembly for drilling, and the bottom inner wall of the dust collection box 5 is fixedly connected with a suction device for dust collection. Dust assembly, the inside of the water ta...

Embodiment 2

[0063] Embodiment two: if Figure 4As shown, a rapid drilling system for detecting deep cracks in concrete. The difference between this embodiment and Embodiment 1 is that: one side of the rectangular box 4 is fixedly connected with two symmetrically arranged hinges 32, and one side of the two hinges 32 The same box door 33 is fixedly connected, and the same door lock 34 is fixedly connected to one side of the box door 33 and the rectangular box 4 .

[0064] Working principle: open the door lock 34 by hand, turn the box door 33 to open the box door 33, unscrew the first screw 42 from the thread groove 38, turn the hand wheel 44, the hand wheel 44 drives the fixed box 41 to rotate, and the fixed box 41 Drive the mounting plate 43 to rotate. When rotating to a suitable angle, screw the first screw rod 42 into the threaded groove 38 to fix the fixed box 41. Rotate the second screw rod 45 by hand, and the second screw rod 45 will lift in the vertical direction Movement, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com