Drilling dust falling device and process for highway construction

A dust suppression device and road technology, which is applied to the driving device, support device, drilling equipment and method of rotary combined drilling, etc., can solve the problems of inconvenient use on the construction site, large size of spraying vehicles, general dust removal effect, etc. Small amount, good dust collection effect, good dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

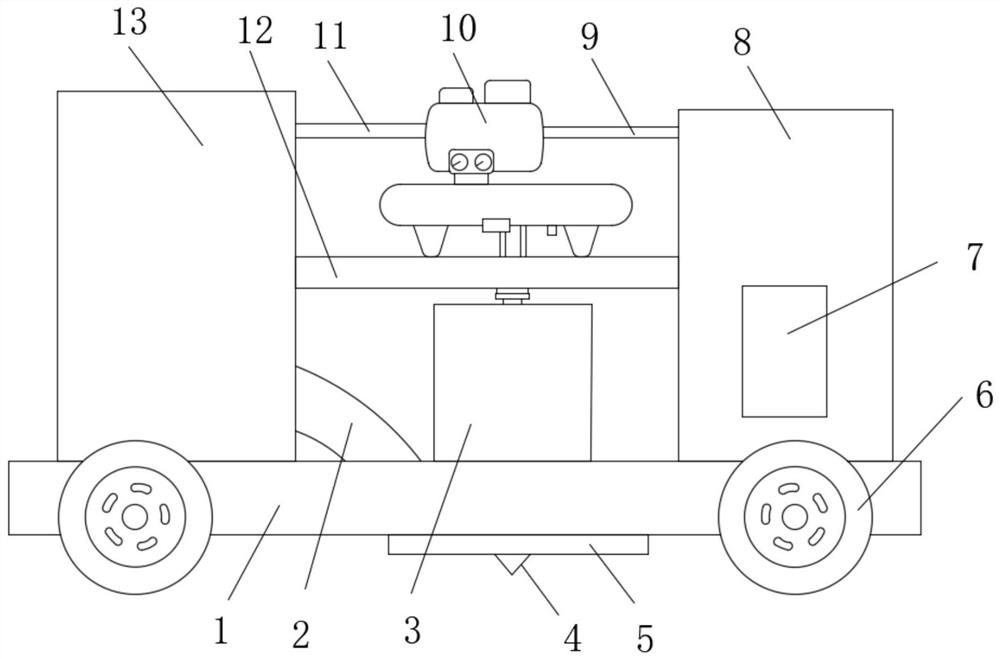

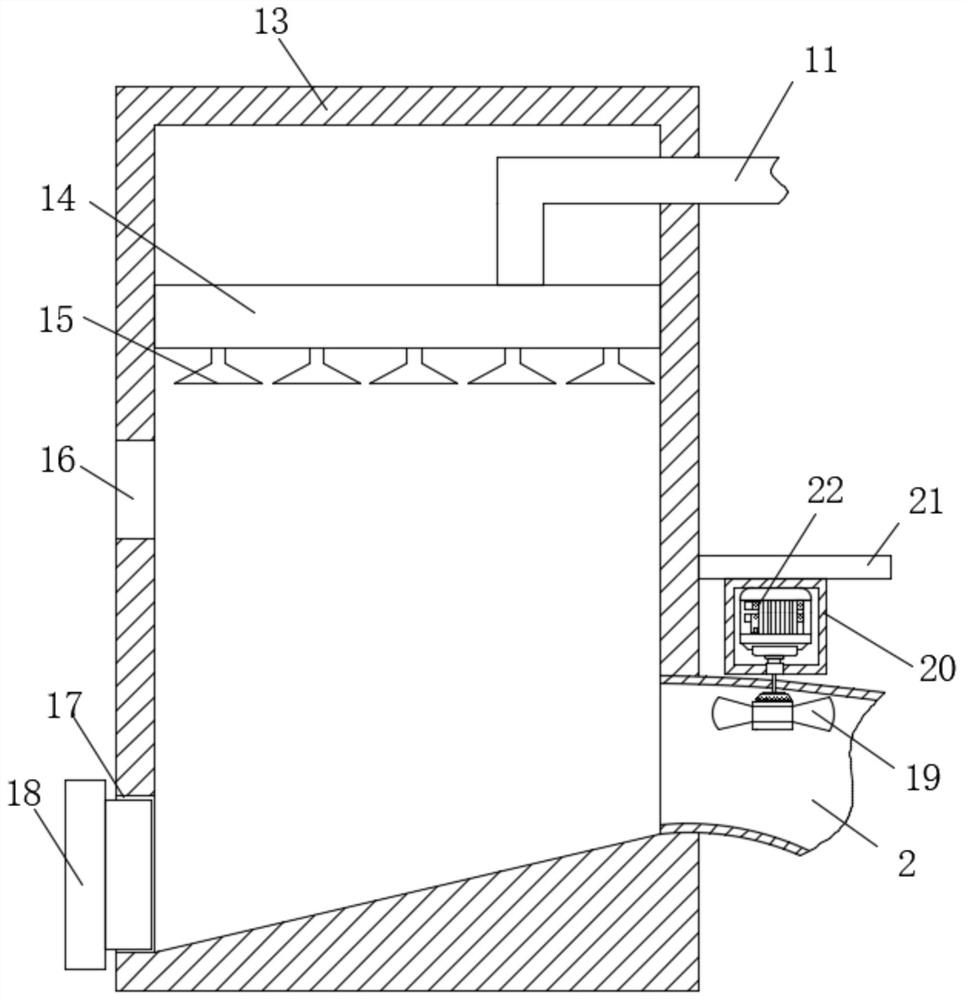

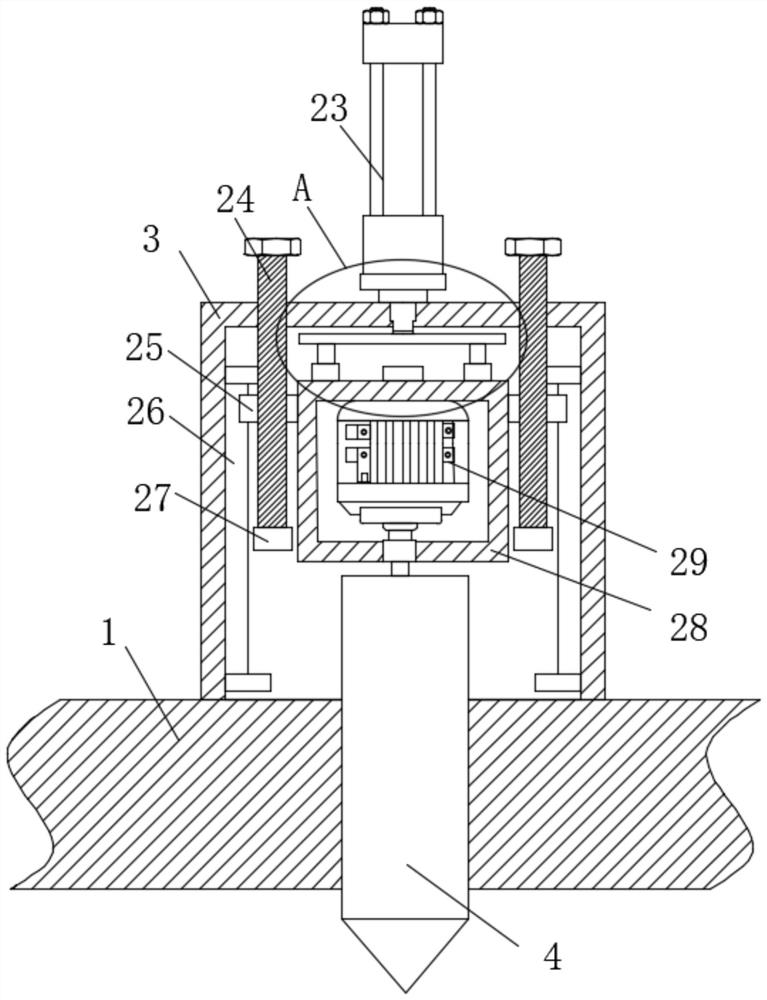

[0038] refer to Figure 1-8 , a drilling dust suppression device for road construction, comprising a base 1, the top of the base 1 is fixedly connected with a fixed box 3, the inside of the fixed box 3 is provided with a drilling assembly for drilling, and the two sides of the base 1 are respectively connected by rotation There are two wheels 6 symmetrically arranged, and the top of the base 1 is fixedly connected with a dust collection box 13 and a water tank 8. The inside of the dust collection box 13 is provided with a dust collection assembly for dust collection, and the inside of the water tank 8 is provided with a water tank for water storage. The water storage assembly, the side of the water tank 8 and the dust collection box 13 close to each other are fixedly connected with the same fixed plate 12, and the top of the fixed plate 12 is fixedly connected with a dust suppression assembly for dust reduction.

[0039] In the present invention, the drilling assembly includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com