Ardealite ball primary balling device

A gypsum ball and ball forming technology, which is applied in the direction of granulation in the rotating tank, can solve the problem of low ball forming efficiency of phosphogypsum balls, and achieve the effect of improving the ball forming efficiency and reducing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

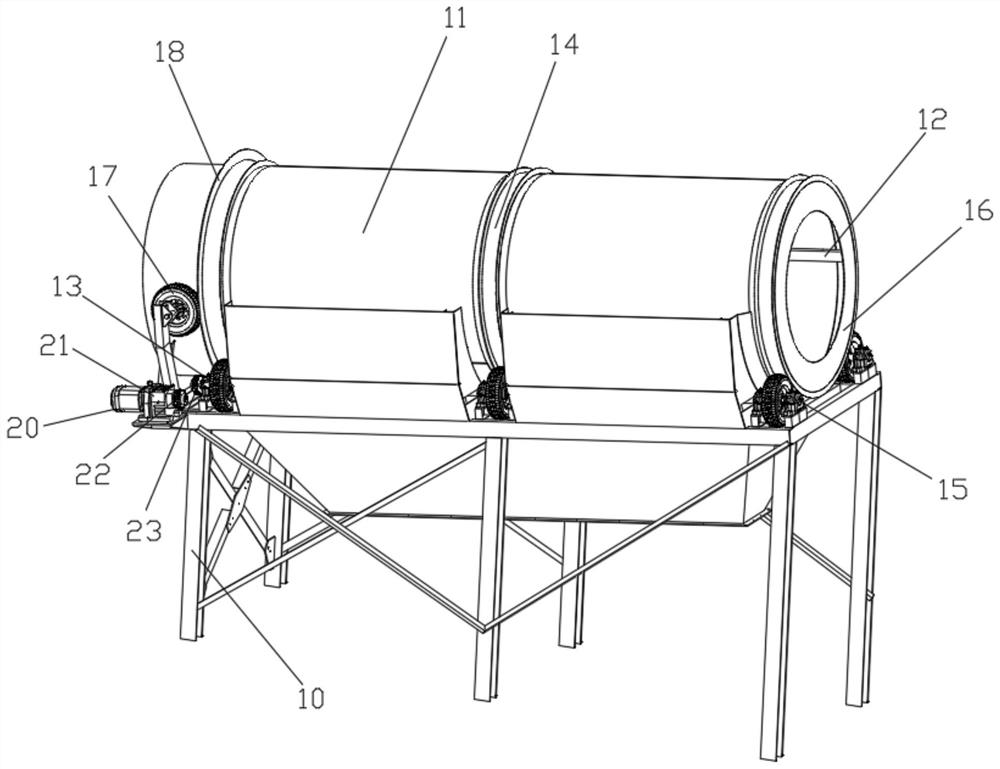

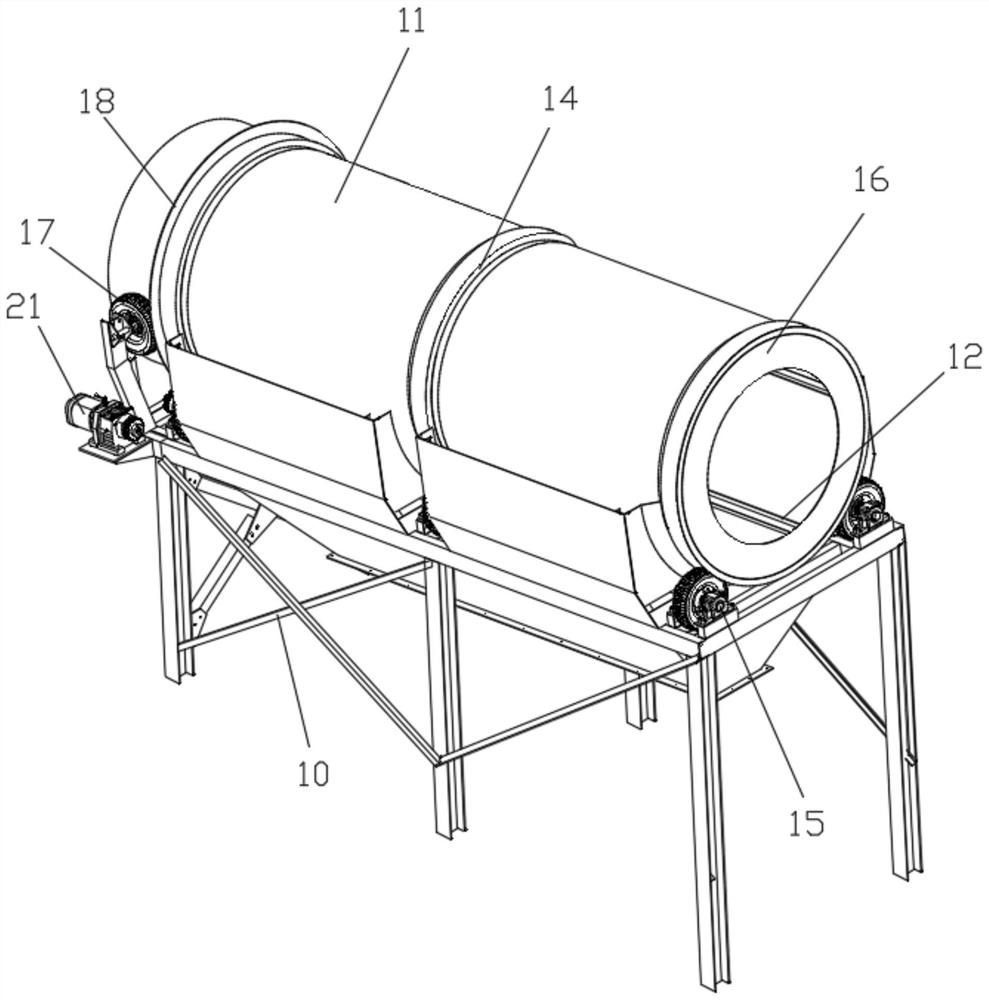

[0020] Reference attached figure 1 And attached figure 2 As shown, the embodiment of the present invention proposes a phosphogypsum ball initial ball forming device, including a bracket 10, on which a ball roller 11 is rotatably mounted, and both ends of the roller 11 are openings. Roller 11 is installed obliquely on the top of the support 10, and a plurality of rollers 13 are installed on both sides of the support 10, and the ball forming roller 11 is supported on a plurality of the rollers 13, and the ball forming roller 11 The outer wall of the outer wall is configured with a plurality of limiting grooves 14, and a plurality of rollers 13 are respectively limited in the limiting grooves 14. The ball forming cylinder 11 is provided with a plurality of ball forming plates 12, and the ball forming plates 12 are A convex pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com