Cuttable cladding panel with a matching pattern, use and manufacturing method thereof

A technology for cladding, patterning, used in manufacturing tools, applications, kitchen tables, etc., to solve problems such as not allowing cladding to be cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095]The drawings are shown in the illustrative non-limiting examples of the present invention.

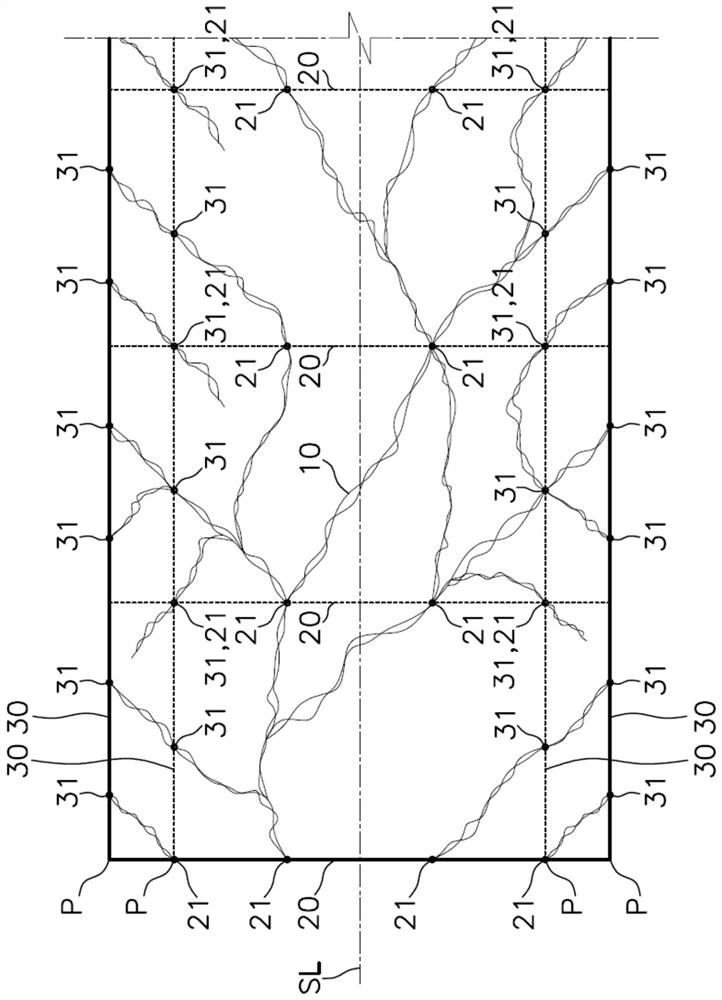

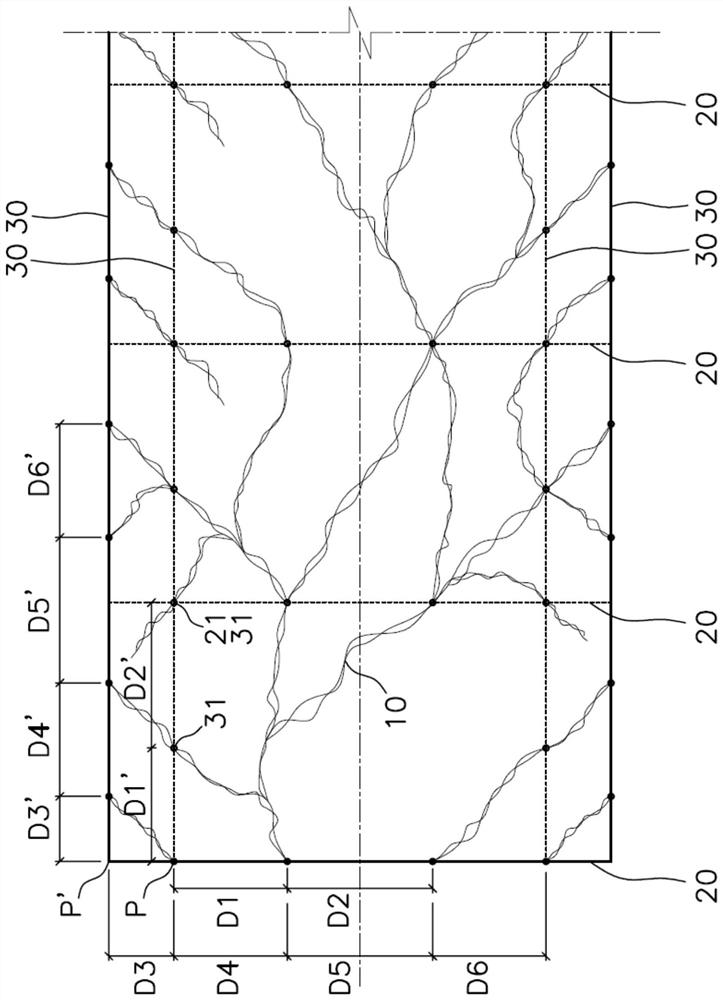

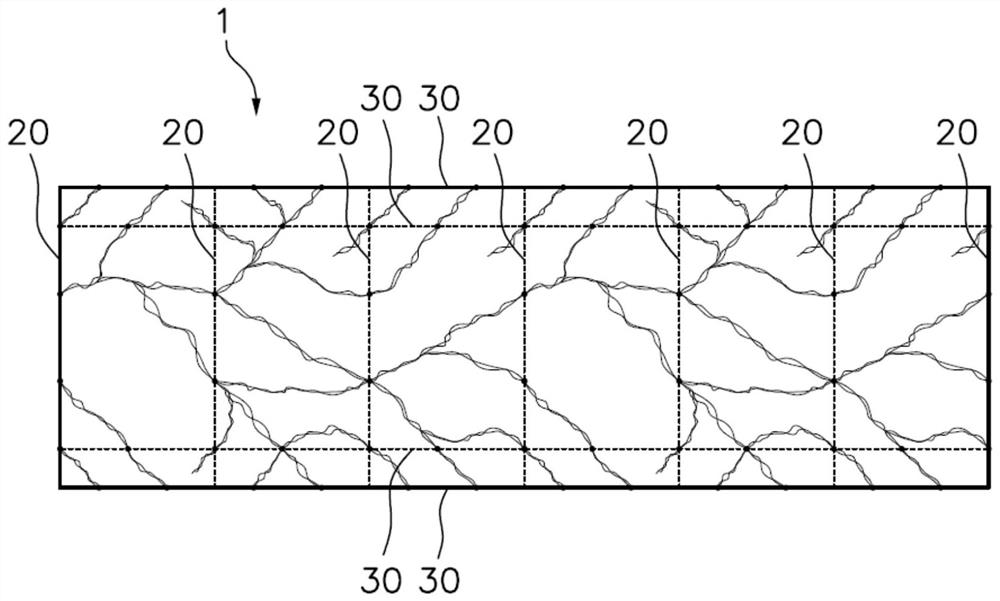

[0096]figure 1 withfigure 2 A enlarged view similar to a portion of the proposed cladding plate 1 is shown in which two longitudinal edges of the cladding plate 1 can be seen, and the lateral edge of the determination of the rectangular cladding plate 1 can be seen.

[0097]The respective portions of the cladding plate 1 also include a longitudinal symmetry shaft SL located in its center, parallel to two longitudinal edges and equidistant with two longitudinal edges, in addition, there are two symmetrical longitudinal cutting lines 30, from discontinuous The line is shown, which is arranged on both sides of the longitudinal symmetry shaft SL.

[0098]The cladding plate 1 also includes three lateral cutting lines 20 which are equal to each other and is perpendicular to the longitudinal symmetry shaft SL.

[0099]The longitudinal and lateral cutting lines 30 and 20 can be printed on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com