Carbon block filler adsorption device

A technology of filler adsorption and carbon block, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of reduced adsorption force of fillers and increased distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

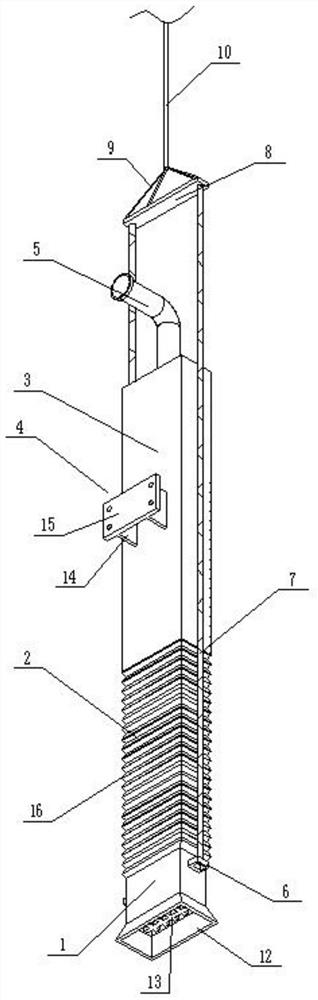

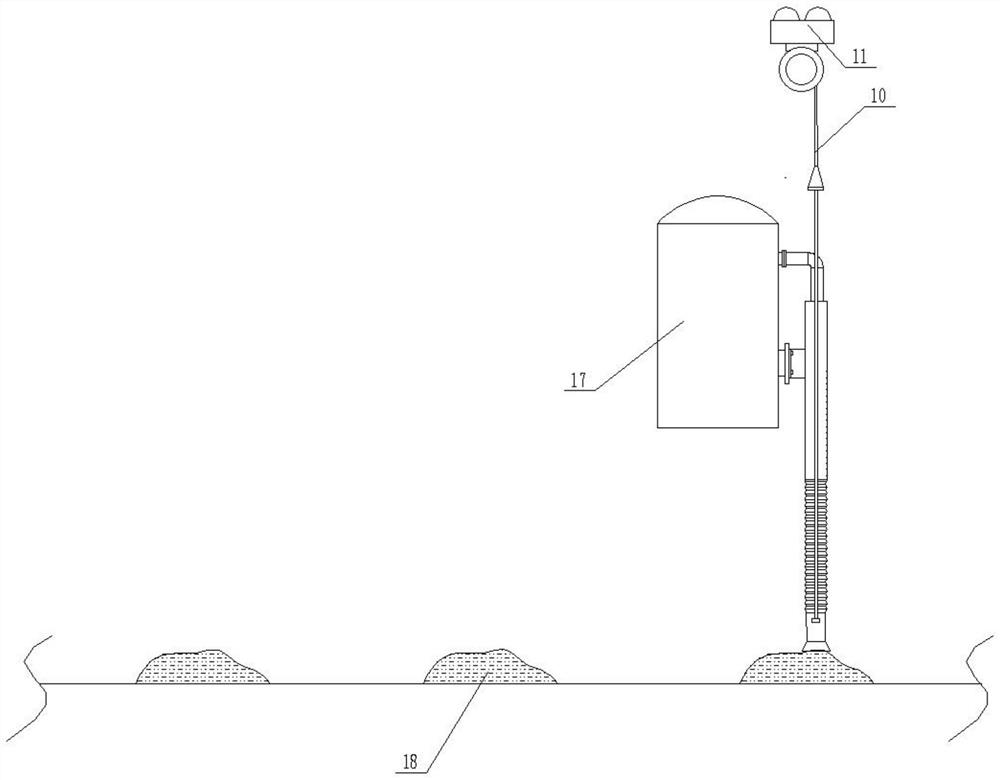

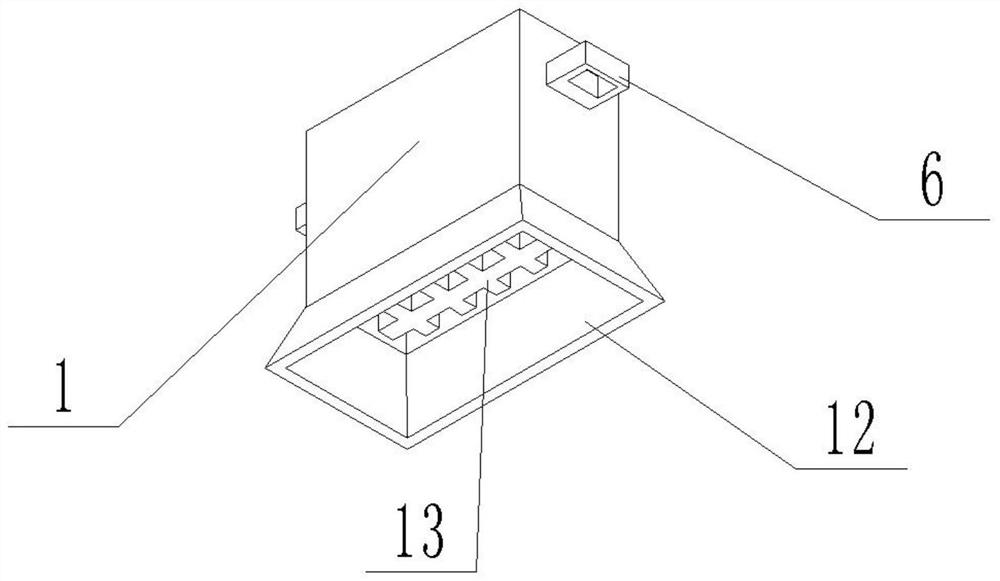

[0019] see Figure 1 to Figure 3 The shown carbon block packing adsorption device includes a suction cylinder 1, the top of the suction cylinder 1 is fixedly connected with a flexible cloth cylinder 2, and a connecting cylinder 3 is fixed on the top of the flexible cloth cylinder 2, and the connecting cylinder 3 A mounting bracket 4 is fixed on the back, a discharge elbow 5 is connected to the top of the connecting cylinder 3, connecting buckles 6 are respectively fixed on both sides of the suction cylinder 1, and a sling 7 is fixed on the connecting buckle 6. The top of the sling 7 is fixedly connected with a hanging plate 8, and the top of the hanging plate 8 is fixedly connected with the steel strand 10 of the winding device through a connecting wire 9.

[0020] When the present invention is in use, the process is as follows. The device is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com