An aluminum square duct installation structure with an external decorative board

A technology for installing structures and decorative panels, which is applied to building components, building structures, and earthquake resistance. It can solve the problems of film sticking effects, manpower consumption, and high technical requirements for film sticking, so as to improve the decorative effect of details. Easy to disassemble and ensure the effect of normal business

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

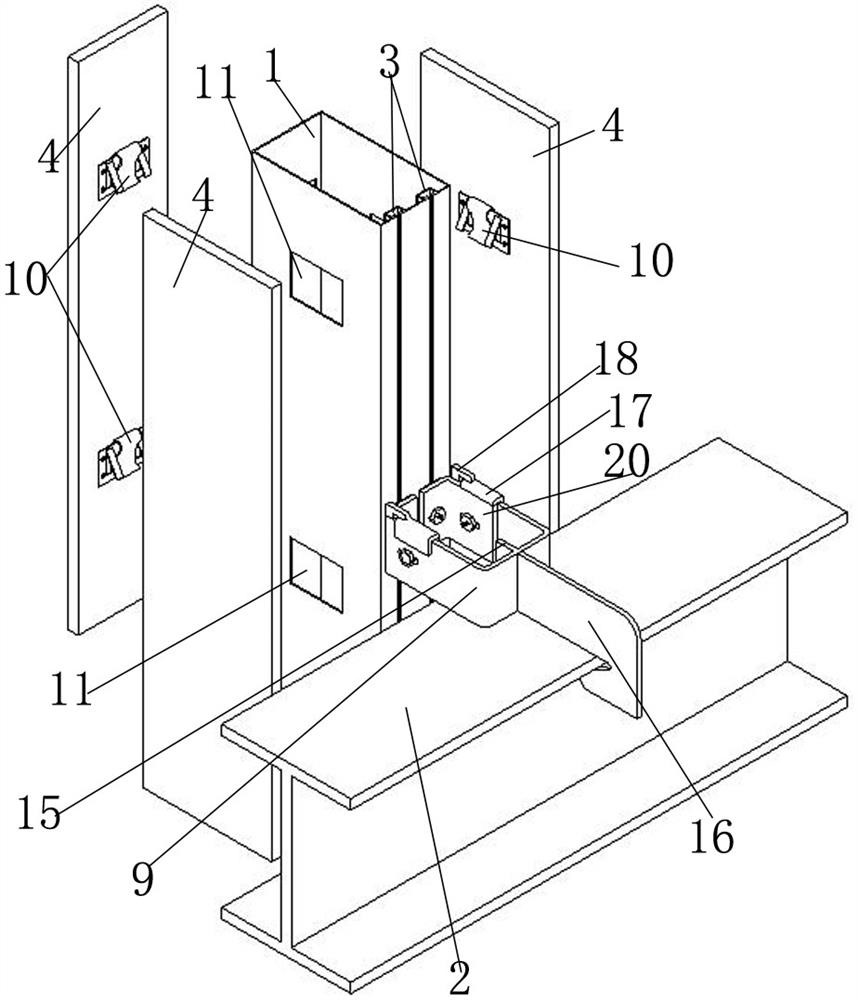

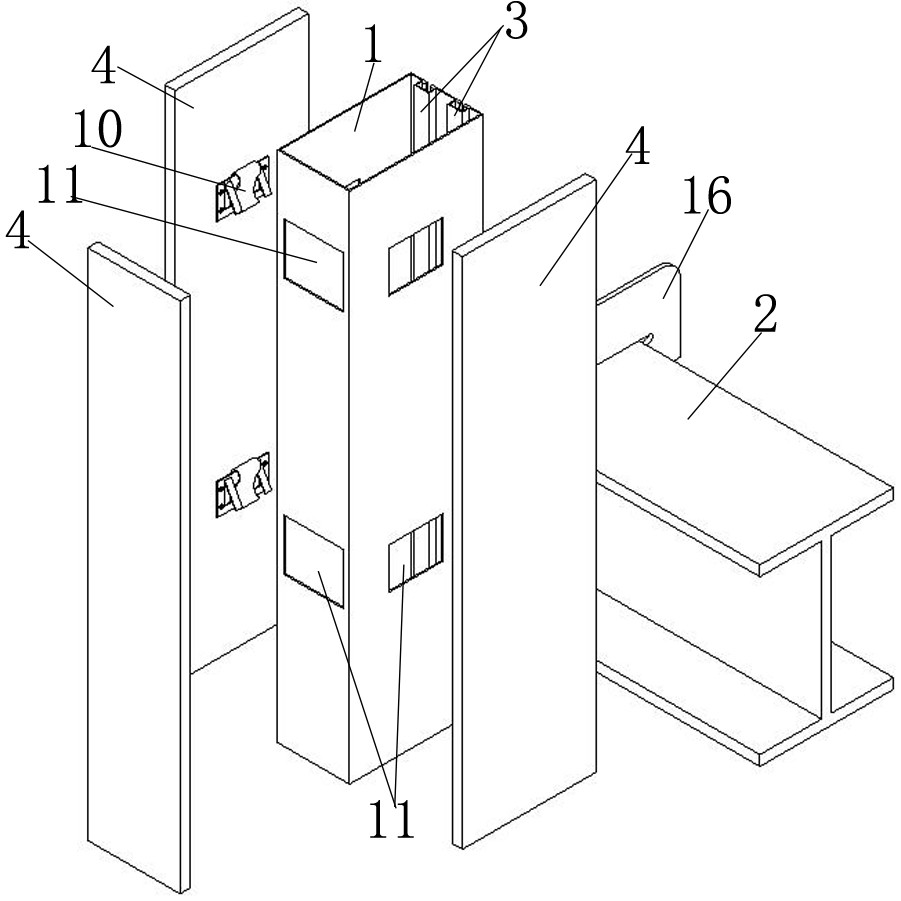

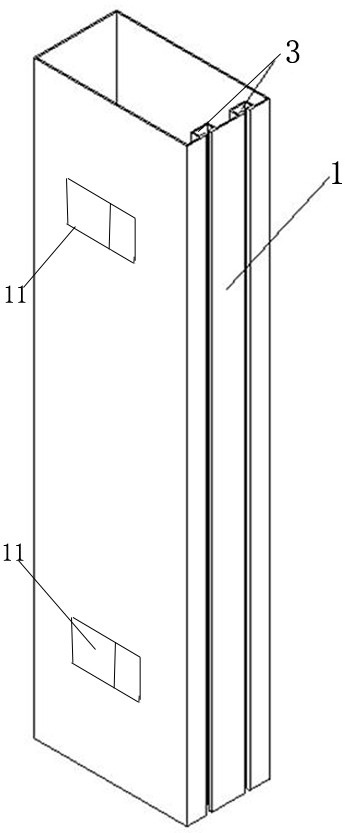

[0035] refer to Figure 1-Figure 15 , the installation structure of an aluminum square with an external decorative board according to the present invention will be described in detail.

[0036] An aluminum square pass installation structure provided with external decorative panels, such as Figure 1 to Figure 5 As shown, including aluminum square pass 1 and steel member 2, such as figure 1 , figure 2 and image 3 As shown, one side of the aluminum square duct 1 is embedded with two parallel bolt installation and fixing grooves 3 along its own length direction, and an external decorative plate 4 is detachably installed on at least one side of the aluminum square duct 1 , also includes two U-shaped corner codes that are interlocked to form a rectangular cylindrical structure, such as Figure 4 and Figure 5 As shown, and the width of the formed rectangular tubular structure is less than or equal to the width of the side wall used to connect the U-shaped corner code on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com