Test device and test method for static stiffness of CNC machine tool spindle unit

A technology of numerical control machine tools and testing devices, which is applied in measuring devices, testing of machine/structural components, elastic testing, etc. It can solve the problems of unsatisfactory accuracy and practicability, prone to errors, etc., and achieve comprehensive and accurate test results. Ideal applicability and ideal test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

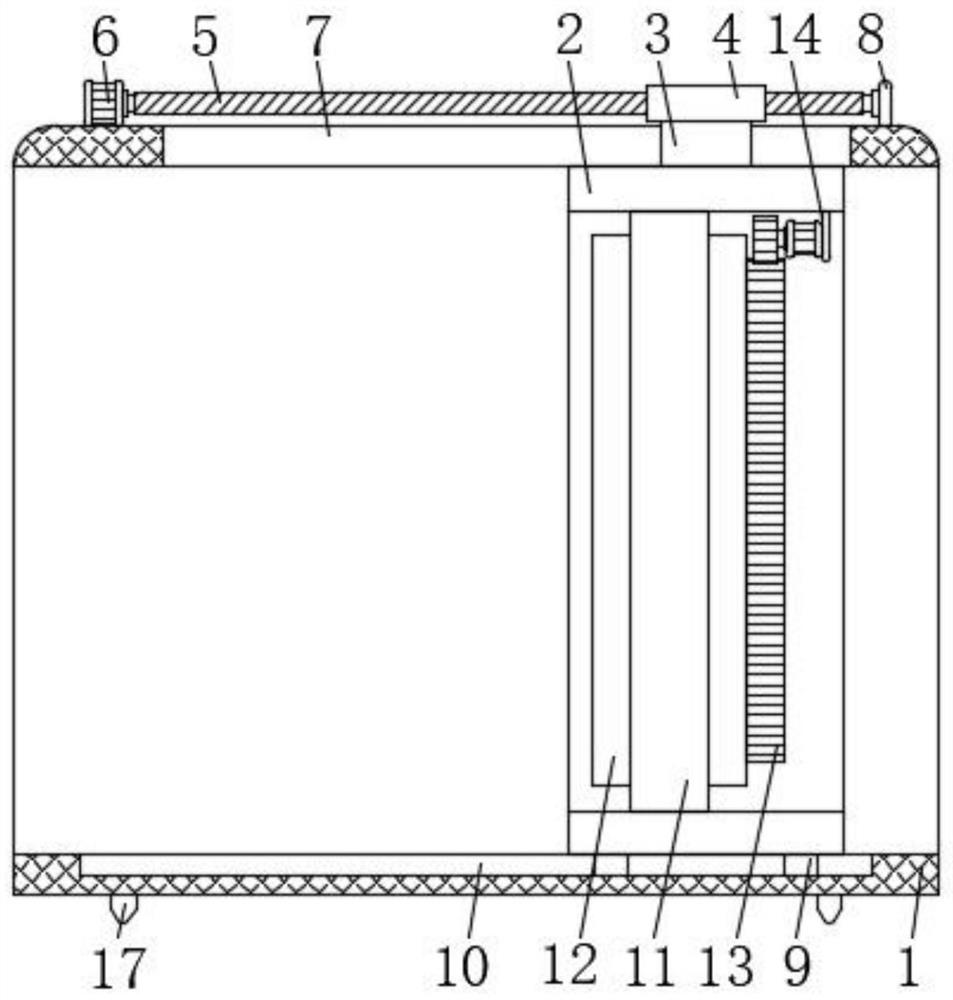

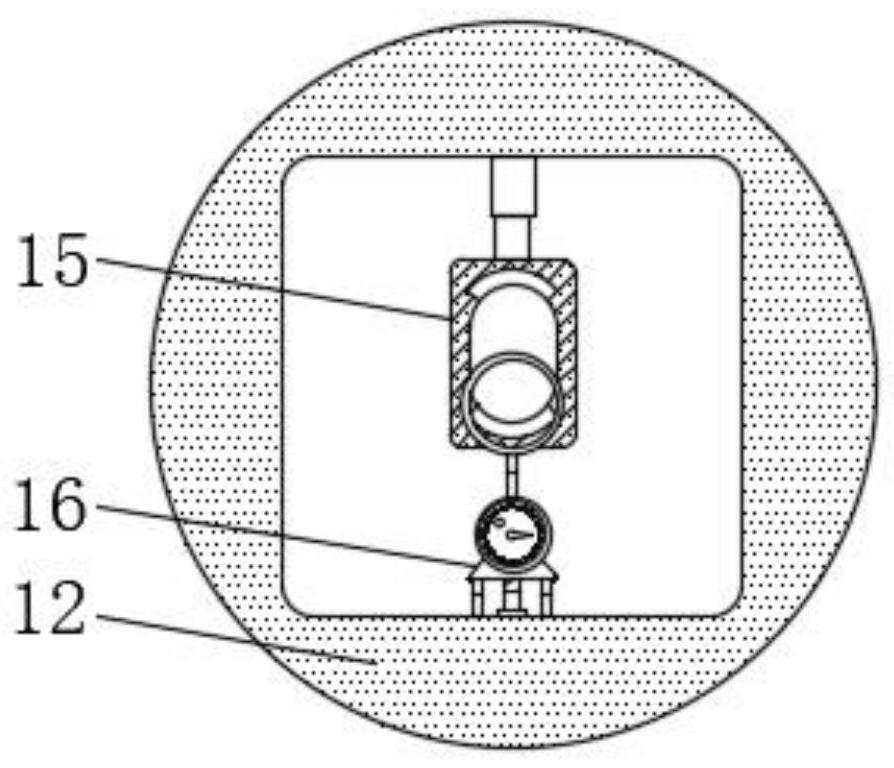

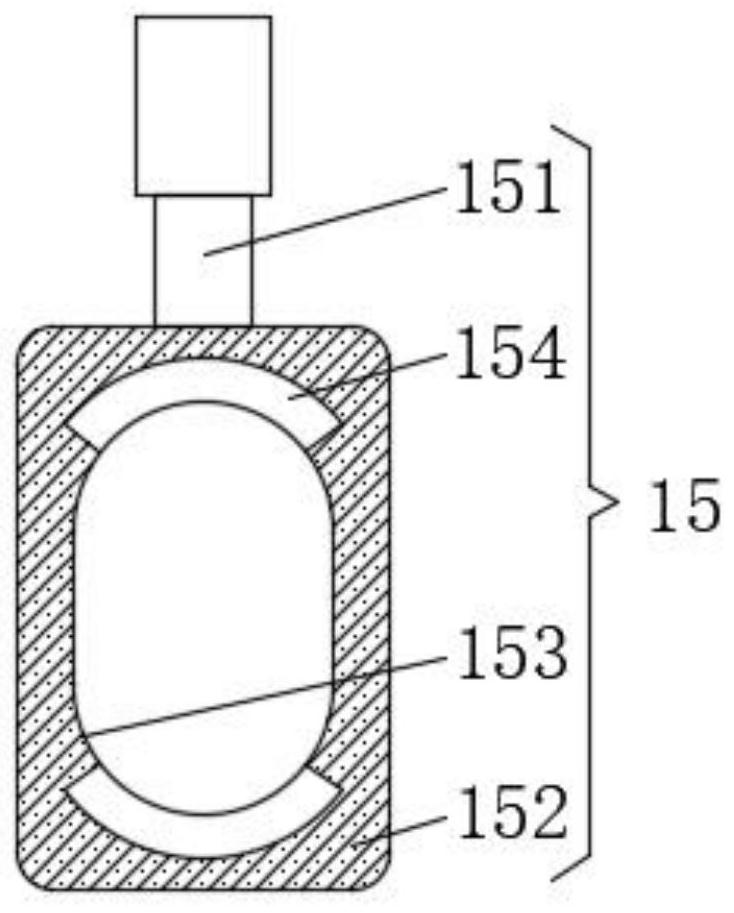

[0036] like Figure 1-8 As shown, the present invention provides a technical solution: a static stiffness test device for a spindle unit of a CNC machine tool, comprising a bottom frame 1, the inner wall of the bottom frame 1 overlaps with the outer surface of the moving frame 2, and the upper surface of the moving frame 2 is connected with the connecting block 3 The lower surface of the connecting block 3 is fixedly connected, and the upper surface of the connecting block 3 is fixedly connected with the lower surface of the threaded cap 4. By setting the first motor 6, the threaded column 5, the threaded cap 4, the connecting block 3 and the moving frame 2, the first motor 6 can be Controlling the rotation of the threaded column 5, at the same time, the threaded column 5 controls the threaded cap 4 and the moving frame 2 to move to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com