Gas filling mother tank containing rack

A technology for placing racks and mother tanks, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, and container discharge methods, etc., can solve the problems of low production efficiency and high labor intensity, and achieve high production efficiency and labor. The effect of low strength and preventing back and forth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

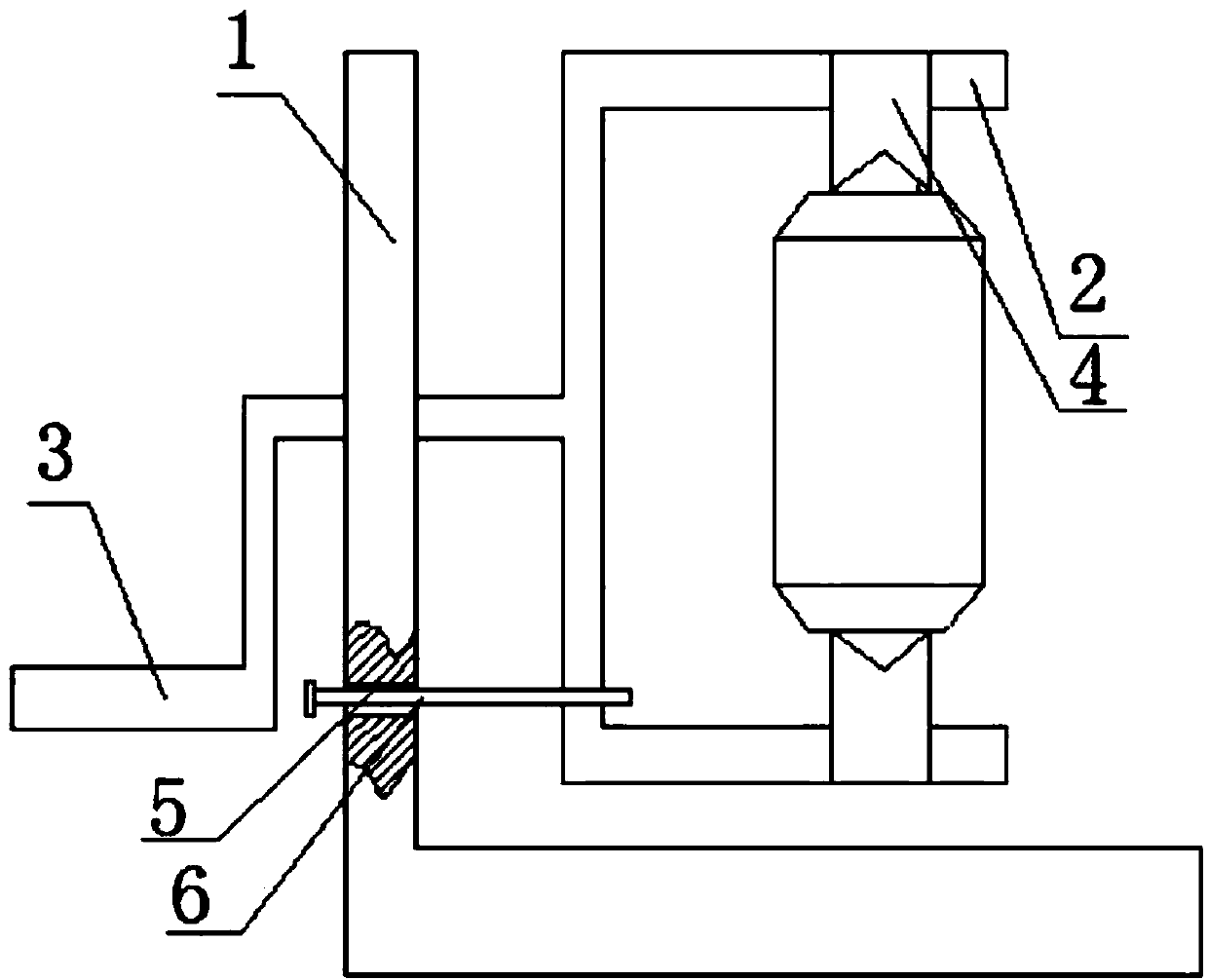

[0010] Such as figure 1 As shown, the gas-filling mother tank placement rack is characterized in that it includes a shelf 1, the shelf is connected to a frame body 2 with a rotating shaft, and there is a crank-shaped handle 3 on the other side of the rotating shaft, and there are clamps in the frame 4. The clamp is a structure that clamps to the side or bottom of the mother tank.

[0011] When in use, the female tank is clamped on the clip, and the handle can be turned when the female tank is to be reversed, which has the advantages of the present invention.

[0012] Furthermore, there are positioning holes 5 on the side of the frame body, and pins 6 are located in the positioning holes.

[0013] In this way, the frame body can be prevented from driving the mother tank to rotate at will, and the use effect is better.

[0014] The above descriptions are only specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com