Built-in permanent magnet dismounting device and method of permanent magnet rotor

A technology of permanent magnet rotor and dismantling device, which is applied in the manufacture of stator/rotor body, electromechanical device, transportation and packaging, etc., can solve the problems of unusable permanent magnet, falling angle of permanent magnet, small permanent magnet, etc., and achieves rapid manufacturing and application. , does not occupy the space, the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

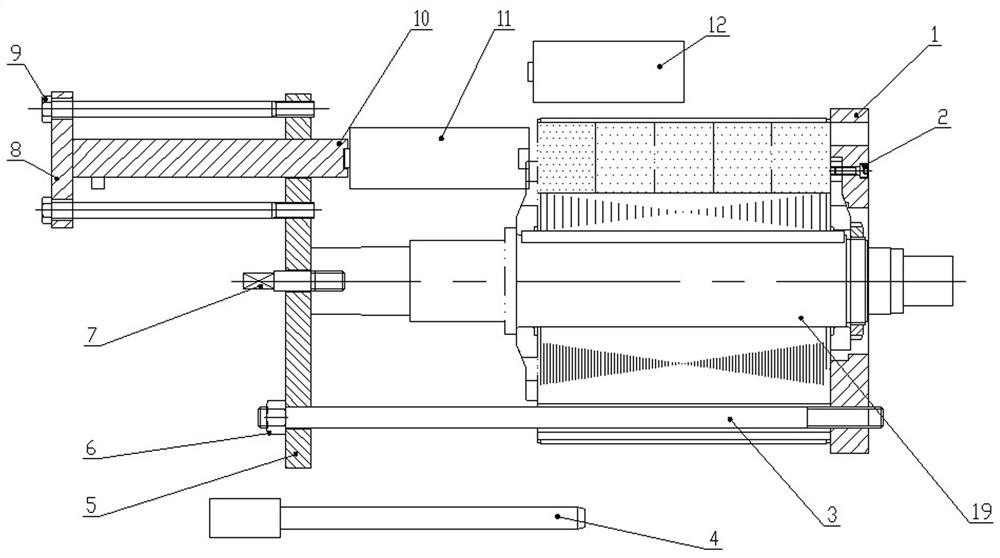

[0025] Such as figure 1 As shown, the present invention is mainly composed of the following 12 parts, including positioning plate 1, screw 2, pull rod 3, positioning column 4, fixing plate 5, nut 6, positioning pin 7, oil cylinder base 8, bolt 9, oil cylinder 10, first Top block 11, second top block 12.

[0026] Part 19 is the rotor assembled with permanent magnets.

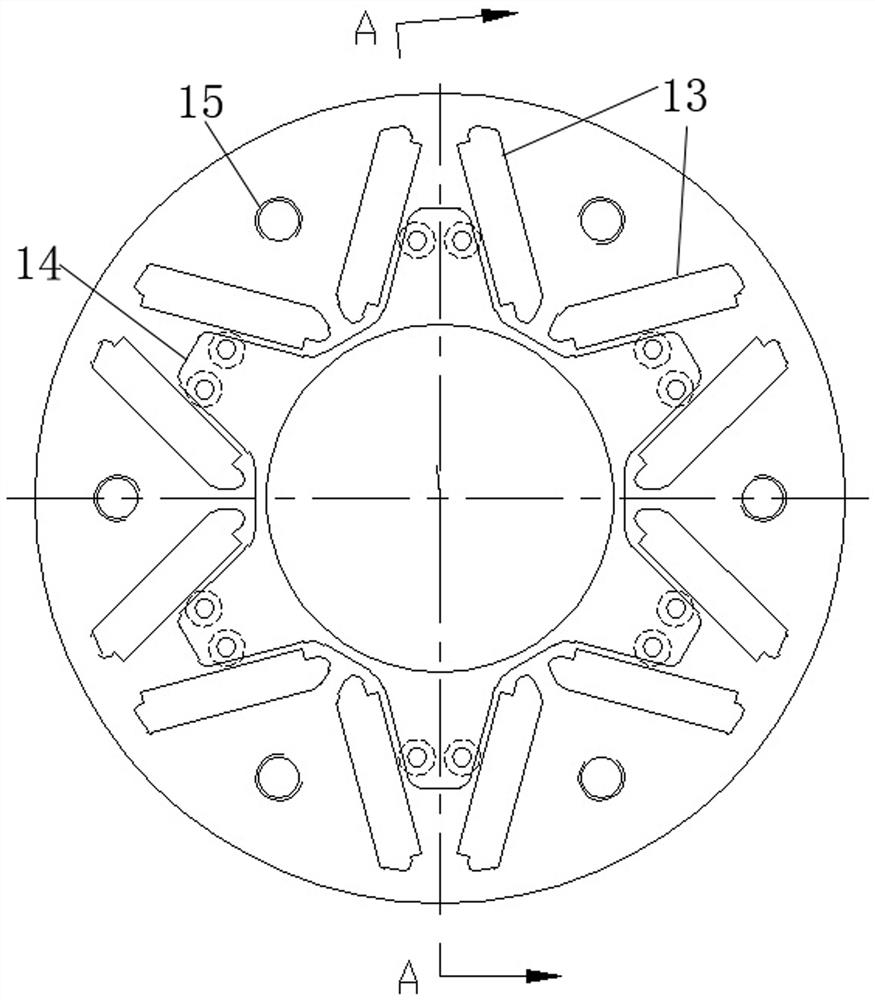

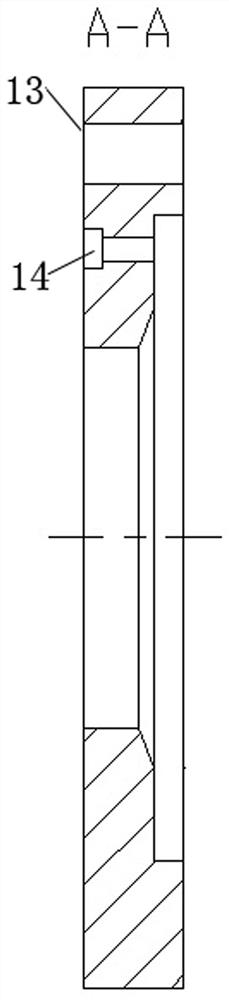

[0027] The positioning plate 1 is fixed on the rotor with screws 2. The positioning plate 1 is made of stainless steel plate. The positioning plate 1 has a through hole (rectangular hole) that is a little larger than the permanent magnet groove, so as to ensure that the permanent magnet can be taken out smoothly after being pushed out. , to avoid being directly attracted to other objects after being pushed out, causing damage to the permanent magnet and other injuries.

[0028] There is a positioning hole (central hole) in the center of the fixing plate 5, and there are 6 second through holes 16 on the plate, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com