Toothbrush head production process and equipment and toothbrush head

A production process and production equipment technology, which is applied in the field of producing toothbrush heads, can solve the problems of copper sheet holes storing dirt, affecting oral health, and affecting appearance, etc., so as to reduce dirt and dirt, improve oral health, and reduce gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

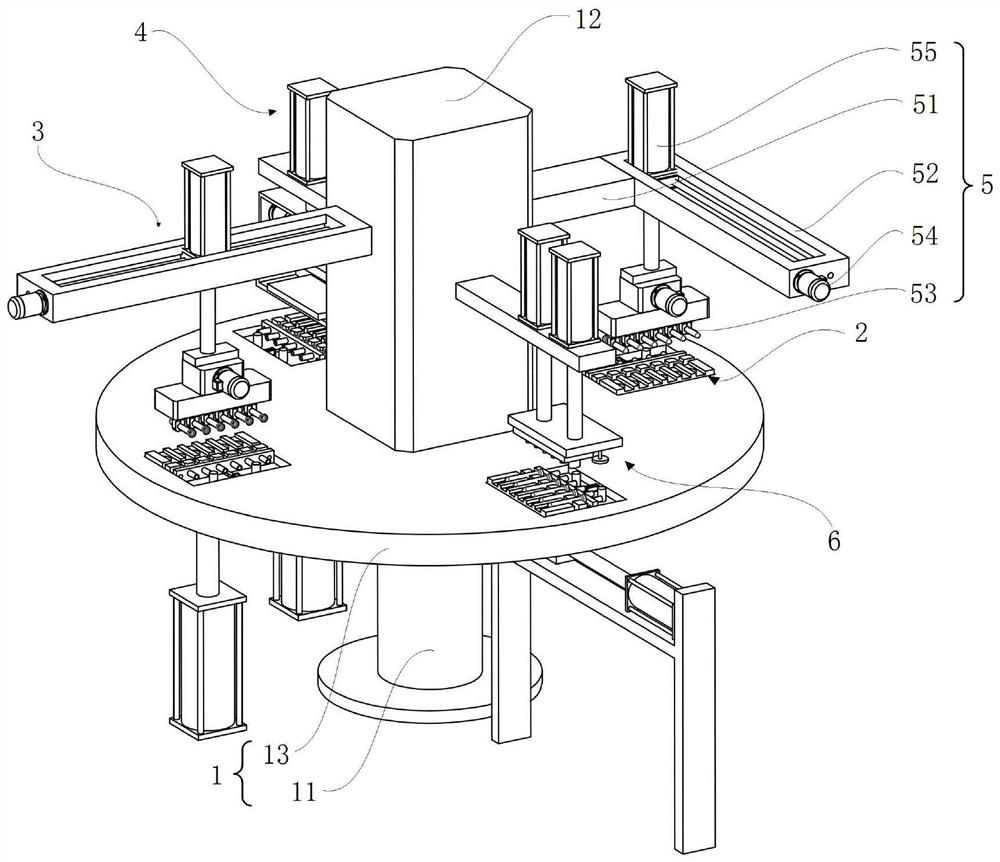

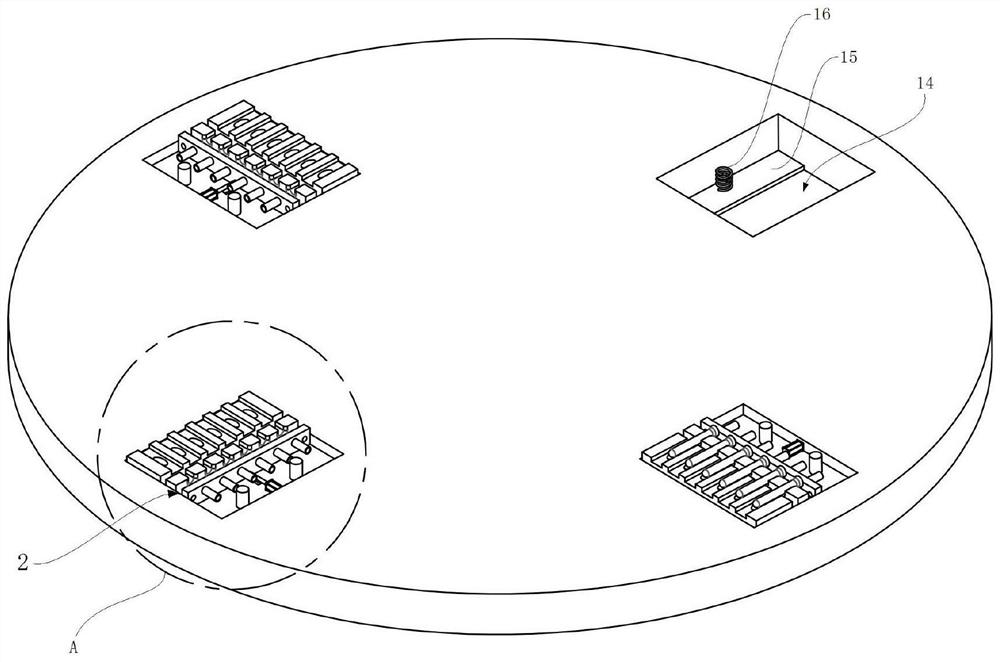

[0050] In order to make the purpose, technical solutions and advantages of this application clearer, the following in conjunction with the attached Figure 1-8 And embodiment, this application is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

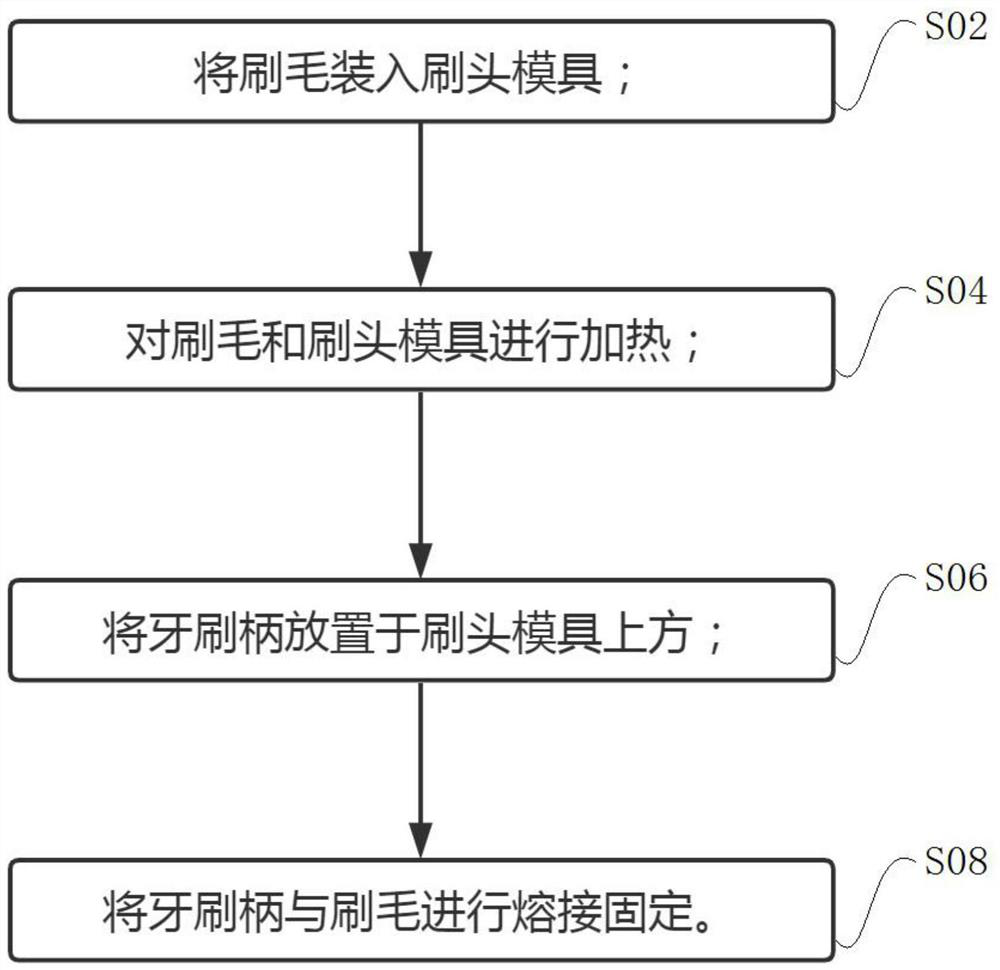

[0051] The embodiment of the present application discloses a kind of toothbrush head production technology, with reference to figure 1 , the toothbrush head production process comprises the following steps:

[0052] S02: Put the bristles into the brush head mould.

[0053]Specifically, the brush head mold is provided with a bristle fixture, and a plurality of hair-planting holes are arranged on the bristle fixture, and the cross-sectional shape of each hair-planting hole can be different, and the hair-planting machine can be used to put the bristles into the hair-planting holes, waiting for subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com