Mop forming machine

A molding machine and mop technology, applied in cleaning machinery, carpet cleaning, floor cleaning, etc., can solve the problems of high structural failure rate, surface wear of mop rod, large outward centrifugal force of the claw grasping device, etc., and achieve stable operation structure. , The effect of stable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

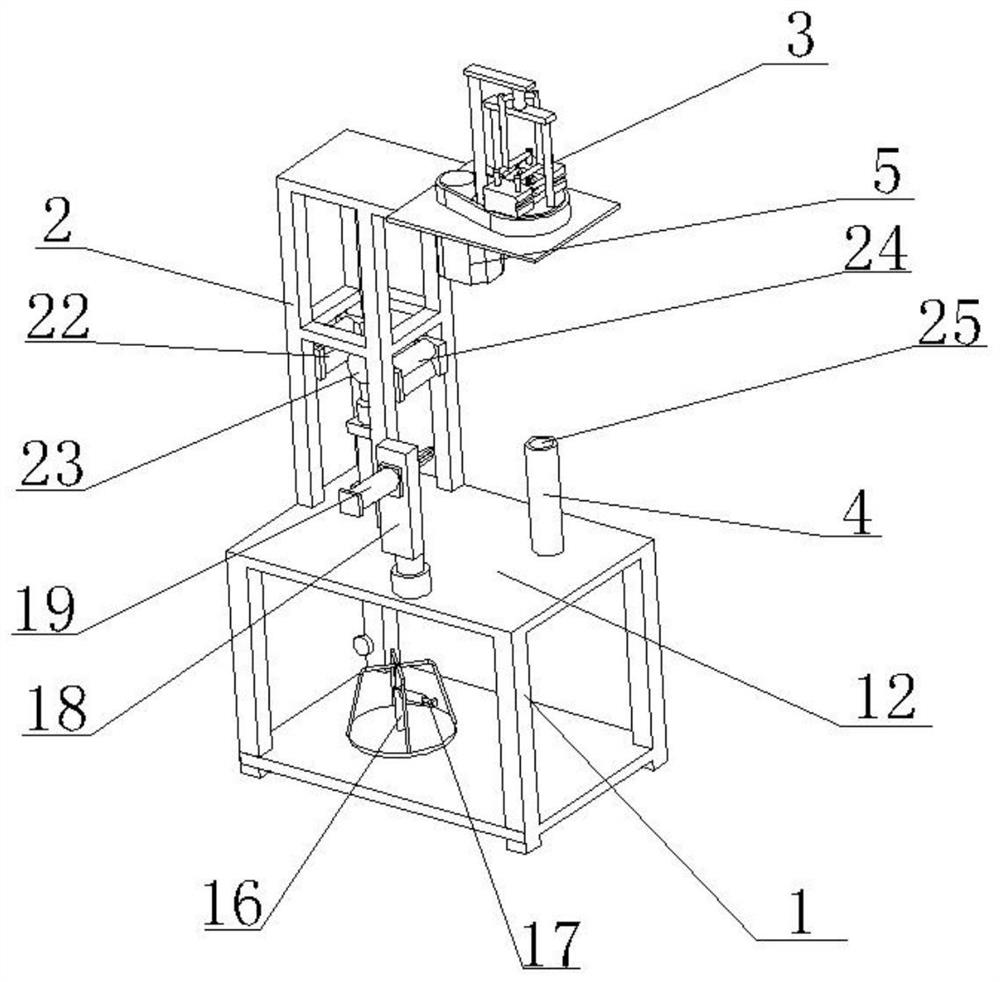

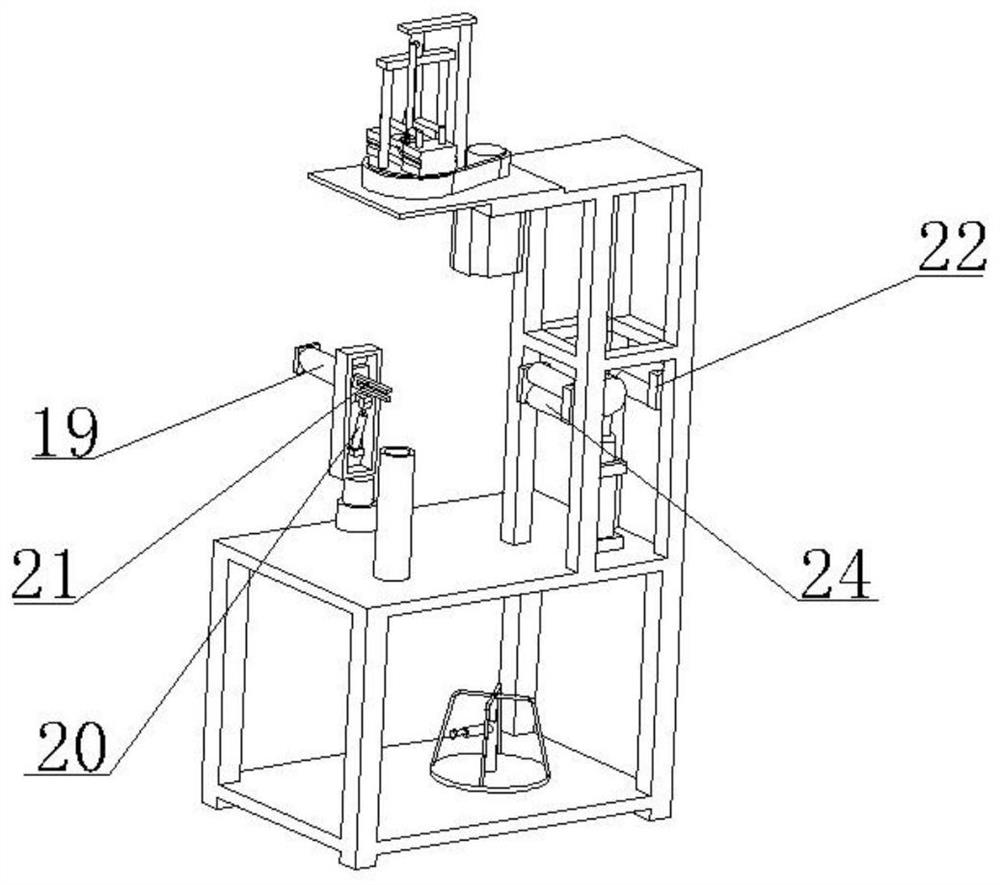

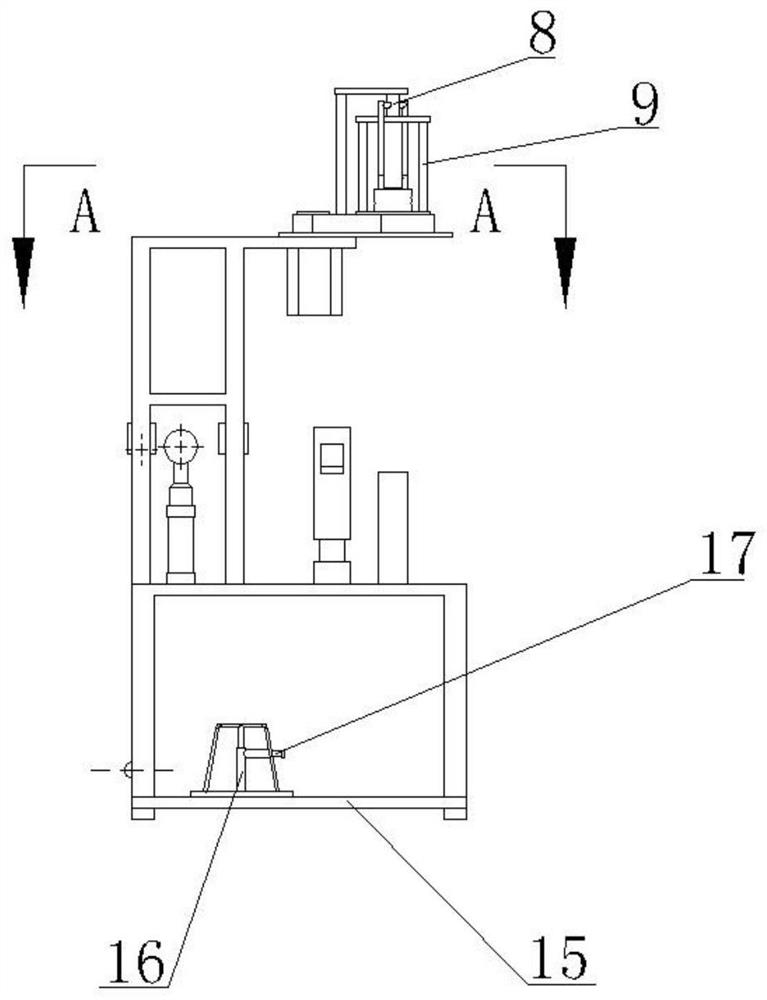

[0028] Embodiment: A mop forming machine, including a base 1, an upper bracket 2, a clamping rotation unit, an outlet unit, a power output unit, and a control center respectively connecting the clamping rotation unit, the outlet unit, and the power output unit. An operating platform 12 is provided on the upper surface of the base 1 , and the upper bracket 2 is fixedly installed on the operating platform 12 . The clamping rotation unit includes a clamping rotation device 3 and a limit support device 4 , and the clamping rotation device 3 is installed on the upper end of the upper bracket 2 . The clamping hole 7 corresponding to the limit support device 4 is provided at the lower end of the clamping and rotating device 3 , and the clamping and rotating device 3 can clamp and rotate the mop rod.

[0029] The clamping and rotating device 3 includes a driving motor 5, a movable turntable 6, a clamping assembly, a rotary joint 8, and a rotating bracket 9. The driving motor 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com