Manufacturing method of digitalized small-size stacked high-retention dental implant operation guide plate

A manufacturing method and a small-sized technology, applied in prosthetics, dentistry, dental implants, etc., can solve the problems of difficult to observe the guide plate fully in place, increase the difficulty and error of the guide plate, and squeeze the surgical operation space, etc., and achieve the retention force. High, increased success rate, improved accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

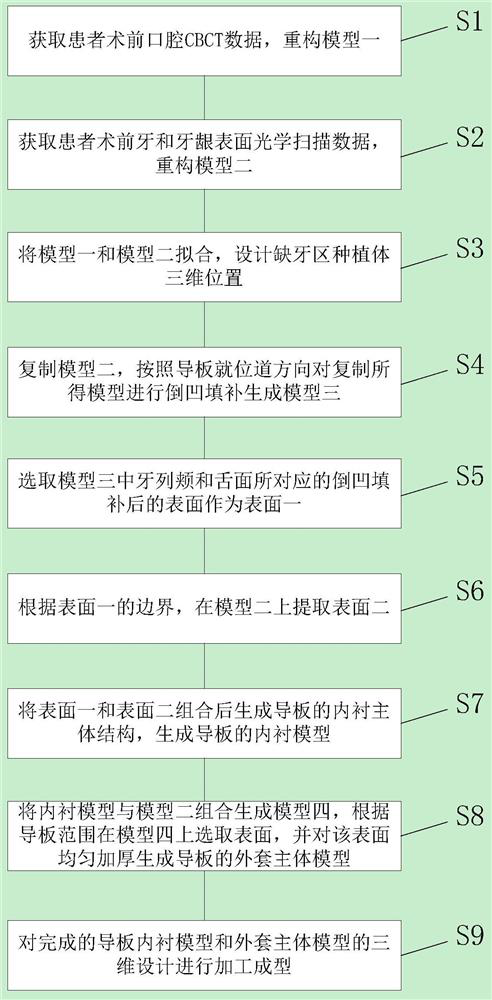

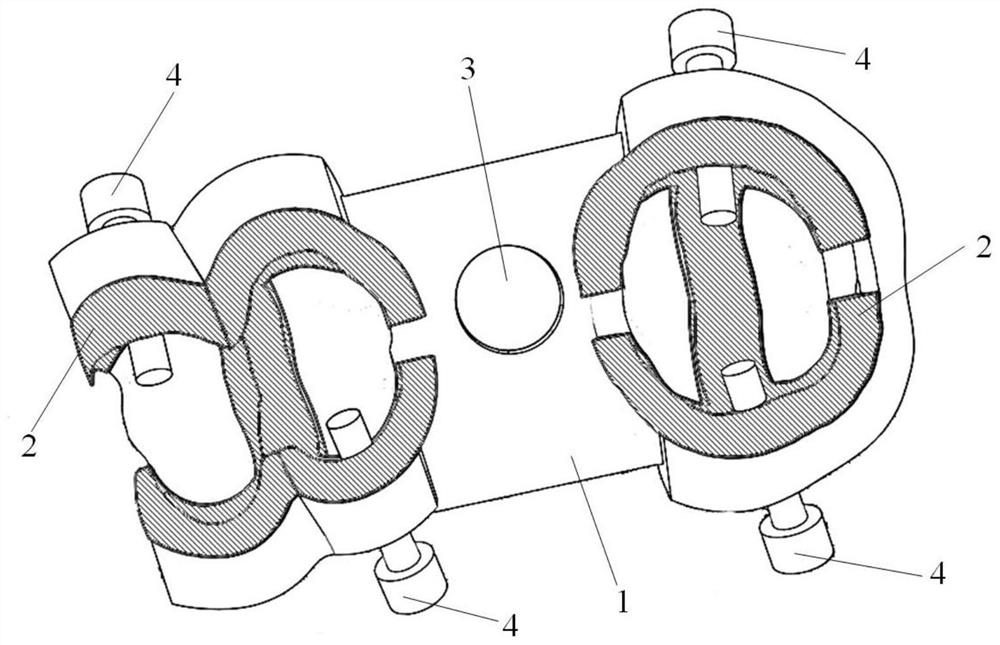

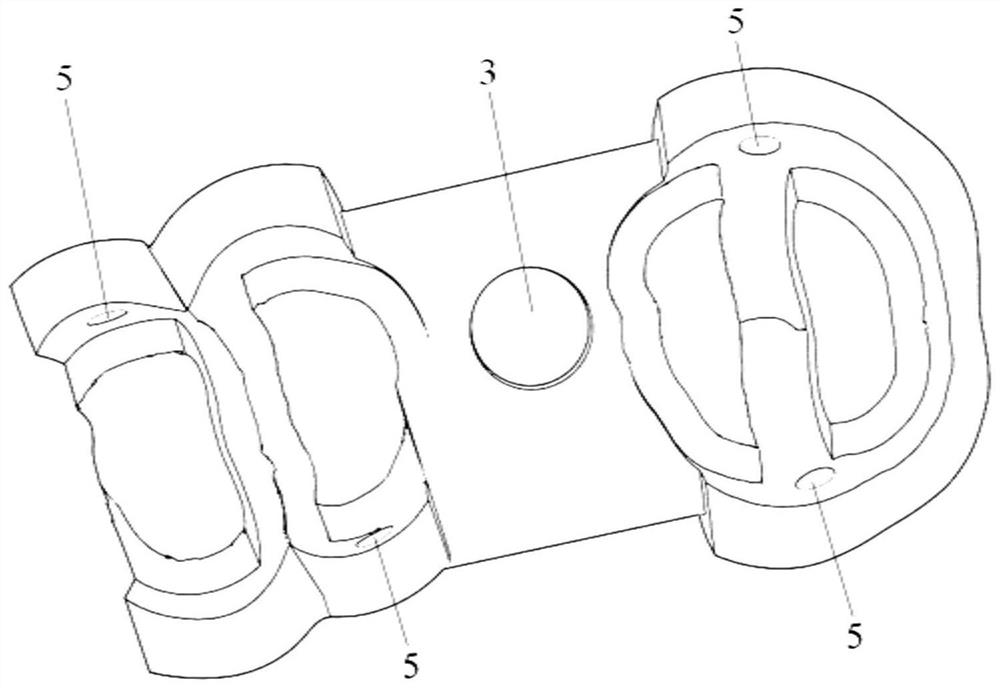

[0049] Example: such as Figure 1 to Figure 6 As shown, a method for making a digital small-size stacked high-retention dental implant surgery guide includes the following steps:

[0050] S1: Obtain the CBCT data of the patient's oral cavity before operation, and reconstruct Model 1;

[0051] S2: Obtain the optical scanning data of the patient's preoperative teeth and gum surfaces, and reconstruct the second model;

[0052] S3: Fit model 1 and model 2, and design the three-dimensional position of the implant in the edentulous area;

[0053] S4: copy model 2, and fill in the undercut of the copied model according to the direction of the guide plate in place to generate model 3;

[0054] S5: Select the surface after filling the undercuts corresponding to the buccal and lingual surfaces of the dentition in Model 3 as Surface 1;

[0055] S6: According to the boundary of surface 1, extract surface 2 on model 2;

[0056] S7: Combine Surface 1 and Surface 2 to generate the main l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com