A production line for making crushed peanuts

A peanut crushing and production line technology, which is used in centrifuges with rotating drums, centrifuges, solid separation, etc., can solve the problems of poor particle uniformity and excessive residual oil in peanut crushing, achieving complete particle integrity and improving the yield of finished products. , the effect of improving the quality of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

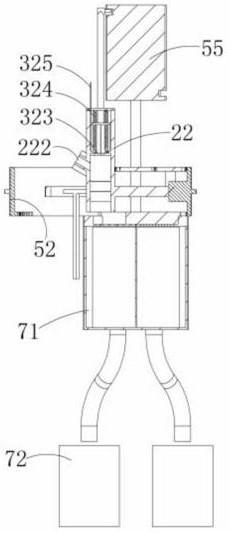

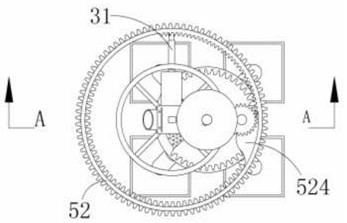

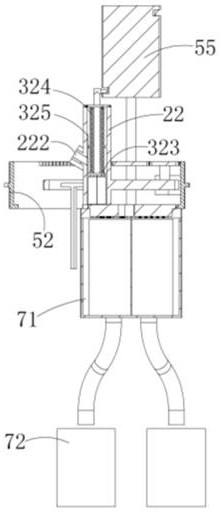

[0061] like Figure 1-2 As shown, a production line for making crushed peanuts, including a rack 1, also includes:

[0062] Tool holder unit 2, such as Figure 3-4 As shown, the tool holder unit 2 is arranged on the frame 1, and includes an annular connecting frame 21 arranged above the frame 1 and a tool holder 22 arranged in the annular connecting frame 21; the tool holder The bottom of the 22 is provided with an outlet 221 for crushed peanuts, and one side is inclined with a feeding port 222; a limit block 223 is provided in the knife holder 22 above the feeding port 222; A lateral guide groove 224 is provided on one side and under the feeding port 222, and a connecting plate 225 connecting the tool holder 22 and the annular connecting frame 21 is provided on the other side. The connecting plate 225 is provided with through holes a2251 and A through hole b2252; a guide hole 211 is provided at a position corresponding to the guide groove 224 on the annular connecting frame...

Embodiment 2

[0095] like Figure 14 , 16-18, in which the same or corresponding parts as in the first embodiment use the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences with the first embodiment are described below; The difference between Example 1 is that:

[0096] Among them, such as Figure 14 As shown, the fried peanuts enter the oil draining unit 8, and the drive unit 4 drives the conical rotating disk 83 to rotate, so that the peanuts spirally descend along the spiral oil draining pipe 84 and drain the oil centrifugally. The oil flows out through the oil draining hole 842 and flows along the cone. The inner wall of the shaped rotating disk 83 flows into the oil receiving groove 85, and the peanuts after oil draining enter into the tool holder 22 through the outlet of the spiral oil draining pipe 84.

[0097] Among them, such as Figure 16a and 16b As shown, at this time, the drive unit 4 drives the annular control disc 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com