Flatting machine on spiral pipe production line

A production line and spiral tube technology, applied in the flattening machine field, can solve the problems affecting the quality of the spiral tube, the thickness of the spiral tube wall is different, and the flattening machine cannot be flattened, etc., so as to achieve rapid flattening, ensure the forming quality and thickness consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

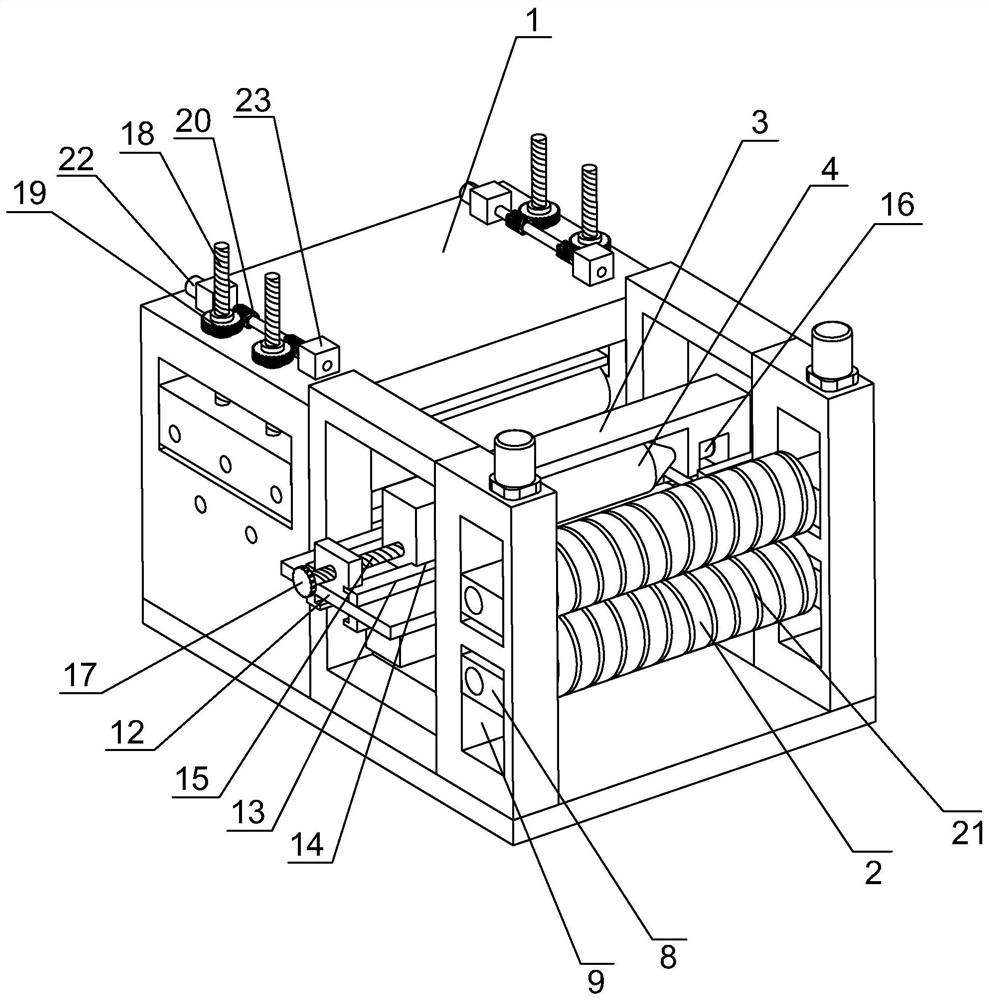

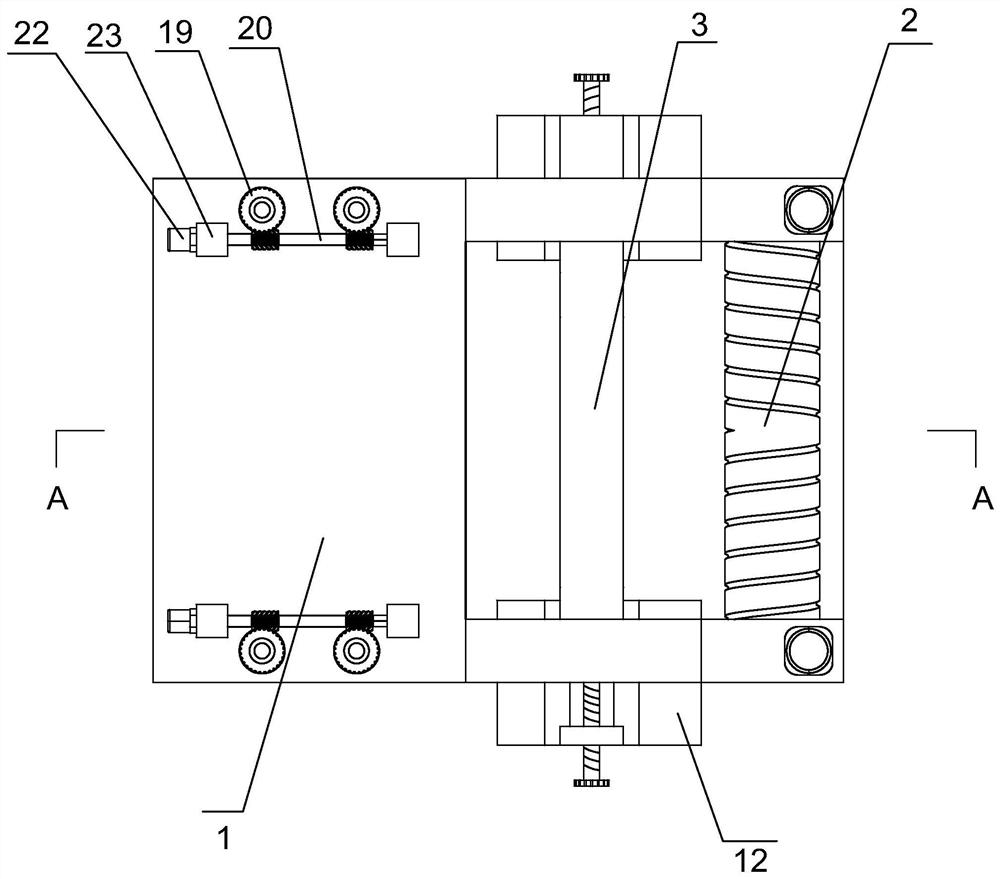

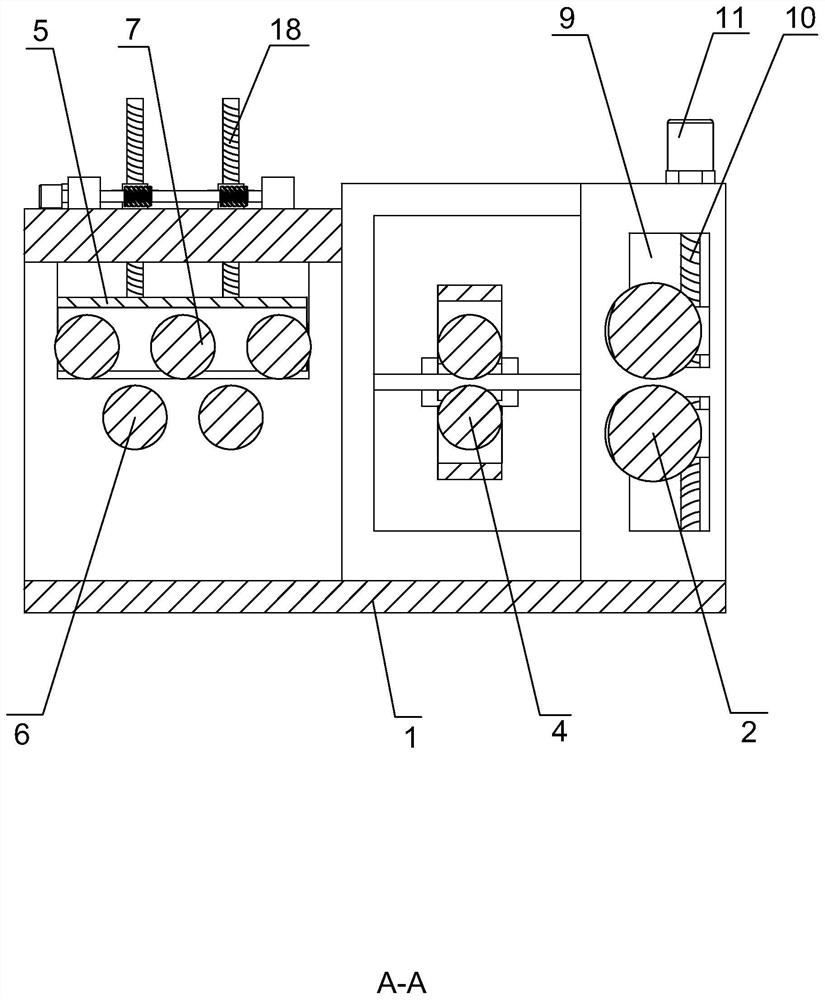

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] refer to figure 1 , is a flattening machine on a spiral pipe production line disclosed by the present invention, comprising a frame 1, the top surface of the frame 1 has a concave structure, and the steel belt can pass through the frame 1 through the concave structure, and the inner edge of the frame 1 The feeding direction of the strip is provided with a pre-pressing mechanism, a shape-adjusting mechanism, and a leveling mechanism in sequence.

[0024] refer to figure 1 with image 3 , The pre-compression mechanism includes two pre-compression rollers 2 arranged in parallel up and down in the frame 1, and the two pre-compression rollers 2 are arranged parallel to each other and their axial direction is perpendicular to the strip feeding direction. Two sections of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com