Trimming and chamfering tool for composite material laminated structure

A composite material layer and chamfering tool technology, applied in the field of trimming tools, can solve the problems of manual processing efficiency and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

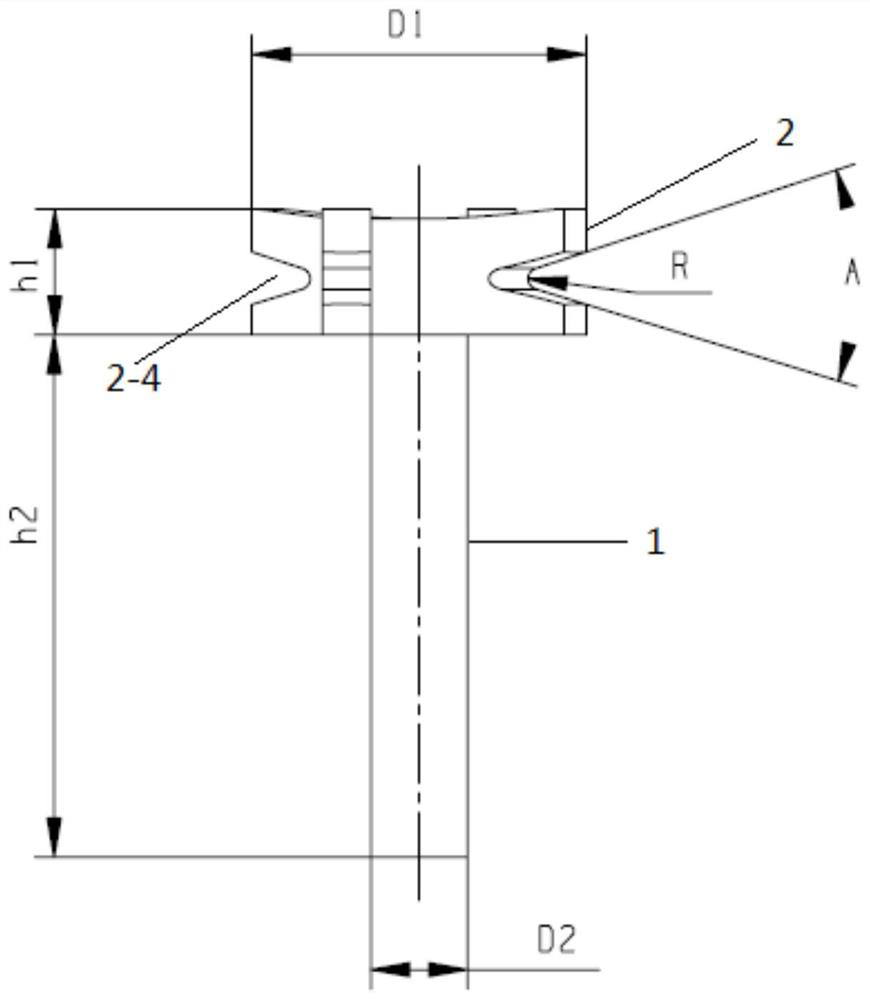

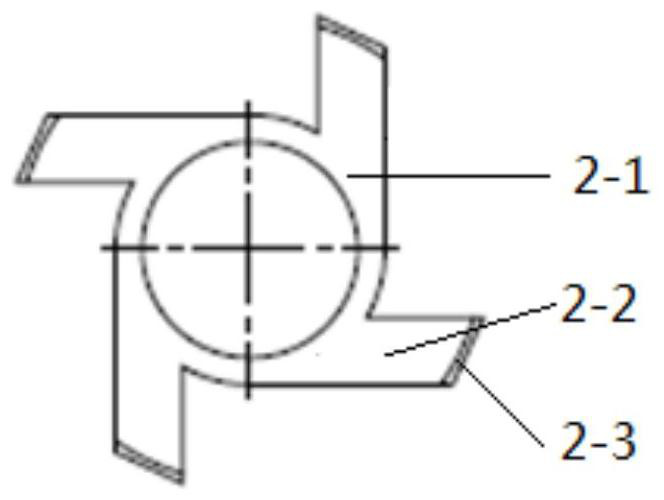

[0041] like figure 1 As shown, the edge trimming and chamfering cutter with composite material laminate structure includes a handle part 1 and a cutter head part 2 . The shank part 1 includes a shank, the shank is cylindrical, the diameter D2 of the shank part 1 is 4 mm, and the height h2 of the shank part 1 is 25 mm. The cutter head 2 includes a connector 2-1 and four cutter heads 2-2, the connector 2-1 is circular, the inner ring of the connector 2-1 is fixedly connected to the top of the handle, and the connector 2- The upper and lower surfaces of 1 are parallel and perpendicular to the handle; each cutter head 2-2 is fixed on the side of the outer ring of the connector 2-1, and is located in the tangential direction, and the other end is provided with a handle parallel to the axial direction of the handle. blade 2-3, one end of the four cutter heads 2-2 is uniformly distributed on the circumference, and the upper and lower surfaces of the connector 2-1 are respectively al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap