Surface fine polishing device based on PS plate production

A fine and grinding mechanism technology, which is applied in the direction of grinding drive devices, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of low working efficiency and uneven grinding of PS boards, and achieve good grinding effects and improved Work efficiency, convenient work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

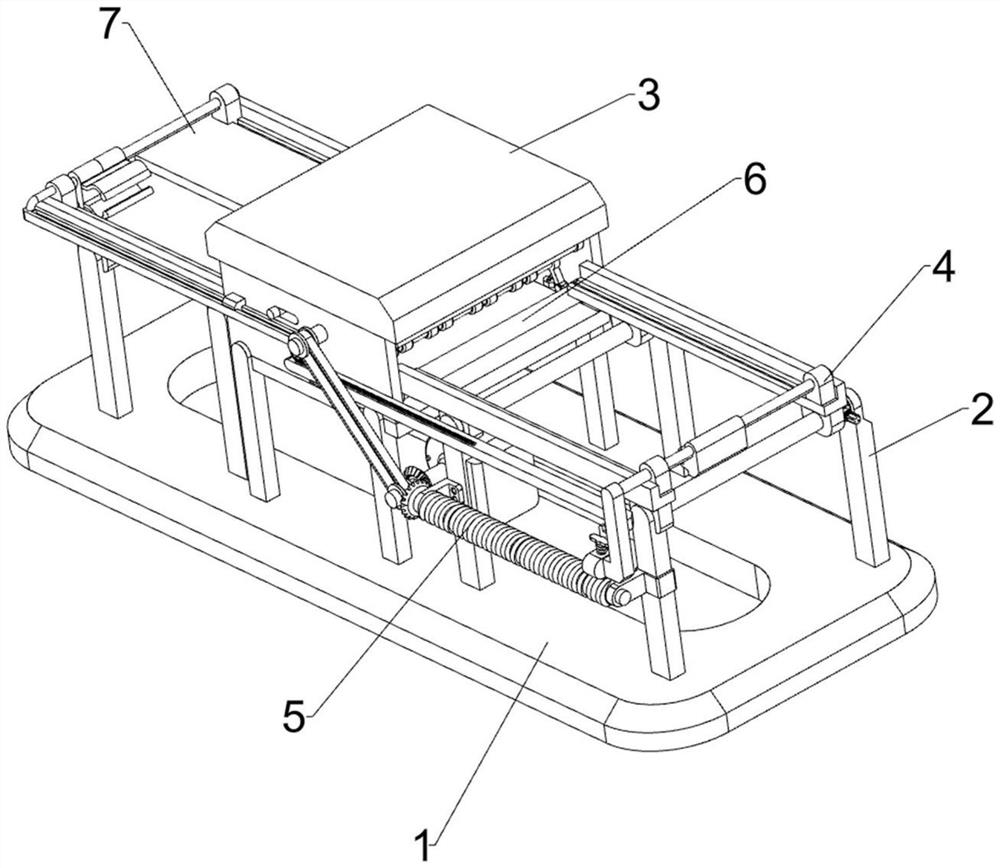

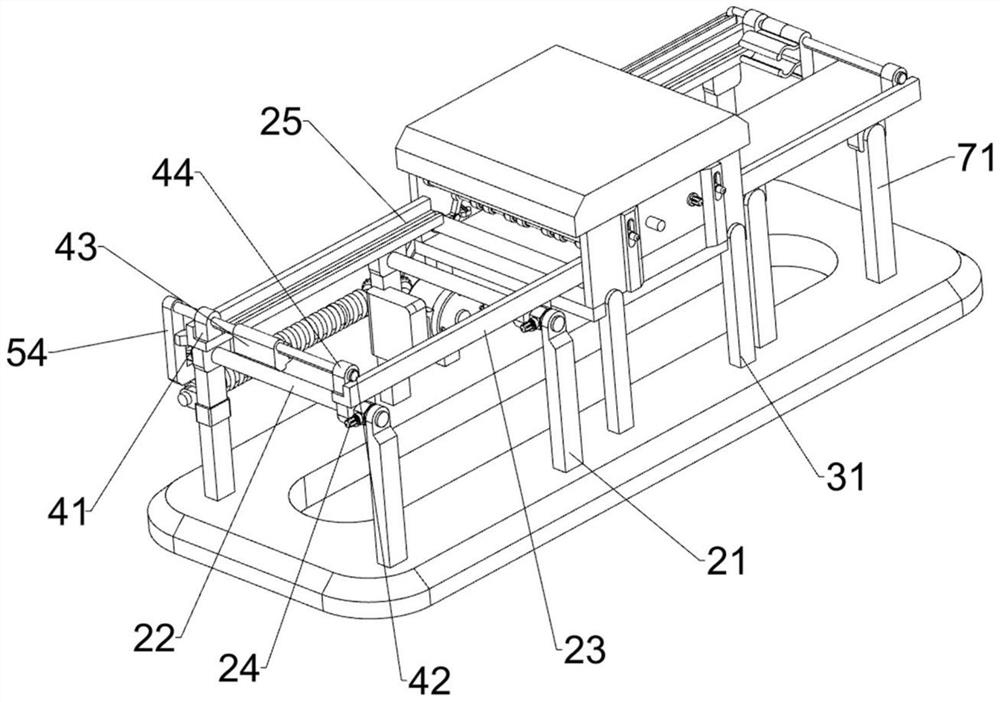

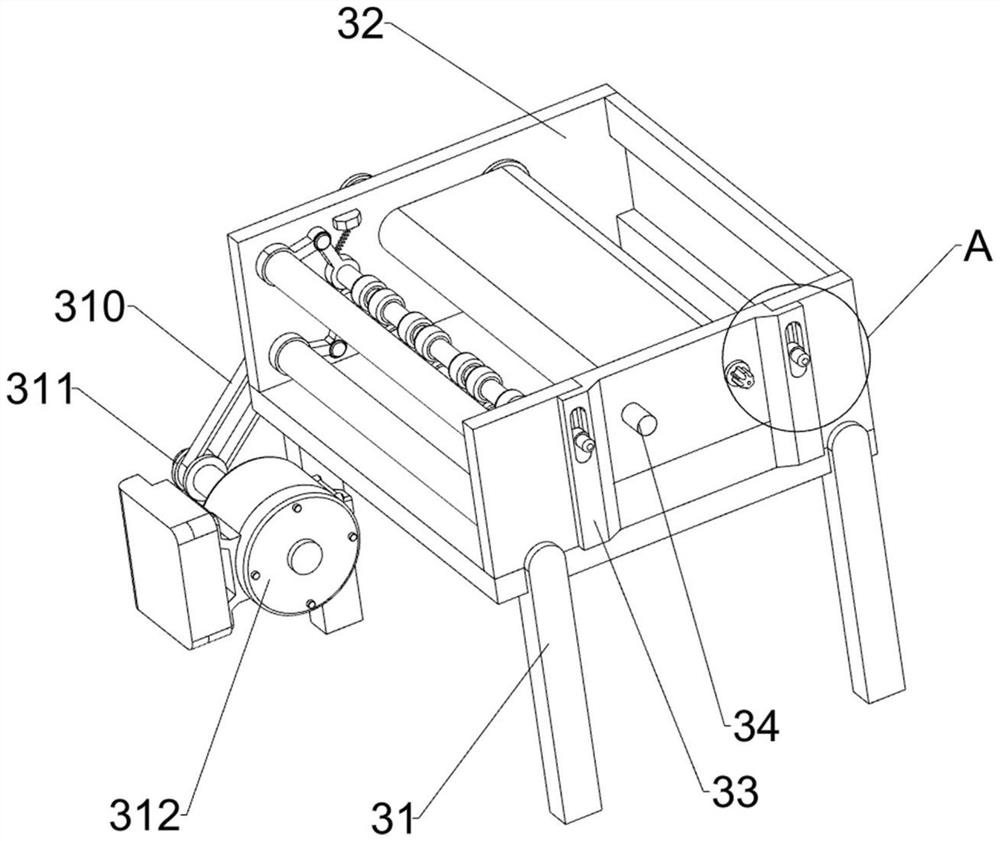

[0082] A surface fine grinding device based on PS plate production, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a feeding mechanism 2, a grinding mechanism 3 and a pushing mechanism 4. The top right side of the bottom plate 1 is provided with a feeding mechanism 2, the middle part of the top side of the bottom plate 1 is provided with a grinding mechanism 3, and the feeding mechanism 2 is provided with a There is a driving mechanism4.

[0083] The feeding mechanism 2 includes a first support column 21, a first connecting rod 22, a moving limit rod 23, a first locking rod 24 and a fixed limit rod 25. A first support column 21, a first connecting rod 22 is arranged between the first supporting column 21 tops on the same side in the longitudinal direction, and a moving stop rod 23 is slidingly provided between the rear sides of the first connecting rod 22, and the first connecting rod The rear sides of the rods 22 are all slid...

Embodiment 2

[0088] On the basis of Example 1, such as figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, an auxiliary moving mechanism 5 is also included, and the auxiliary moving mechanism 5 includes a first fixed block 51, a groove cylinder 52, a bevel gear 53, a connecting block 54, a slide bar 55, a second spring 56 and a second fixed block 57, The first support column 21 front side middle part of the front side is provided with the first fixed block 51, and between the first fixed block 51, the grooved cylinder 52 is arranged in rotation, and the left side of the grooved cylinder 52 and the output shaft of the motor 312 are all provided with cones. The gear 53 and the bevel gear 53 are meshed with each other. The front side of the first fixed rod 42 is provided with a connecting block 54. The lower part of the left side of the connecting block 54 is provided with a second fixed block 57. The front side of the second fixed block 57 rotates and slides. Slide bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com