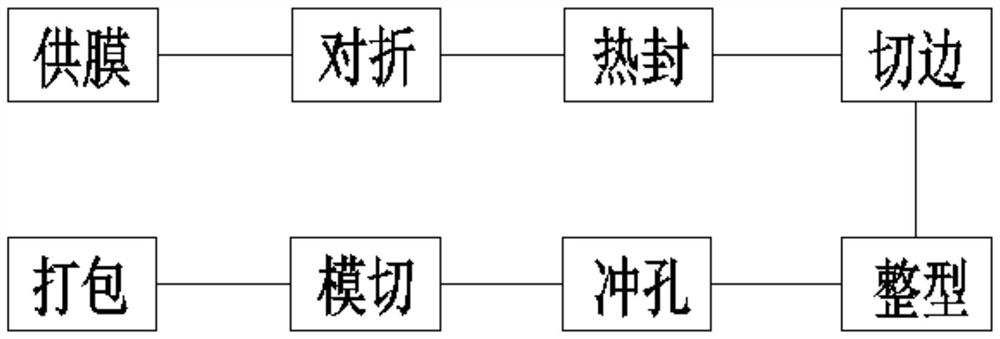

A three-side sealing bag making process

A technology of three-side sealing and craftsmanship, which is applied in bag making operations, container manufacturing machinery, flexible container manufacturing, etc. It can solve the problems of inability to process the bottom and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] S8: packing, the packaging bag of processing and shaping, and manually packing the box.

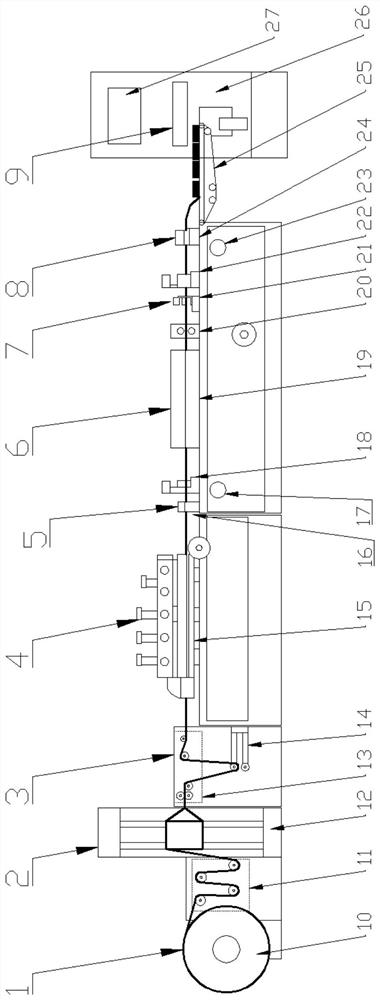

[0055] In this embodiment, the half-folding device includes a frame, and the frame includes a first column 125, a second column 126,

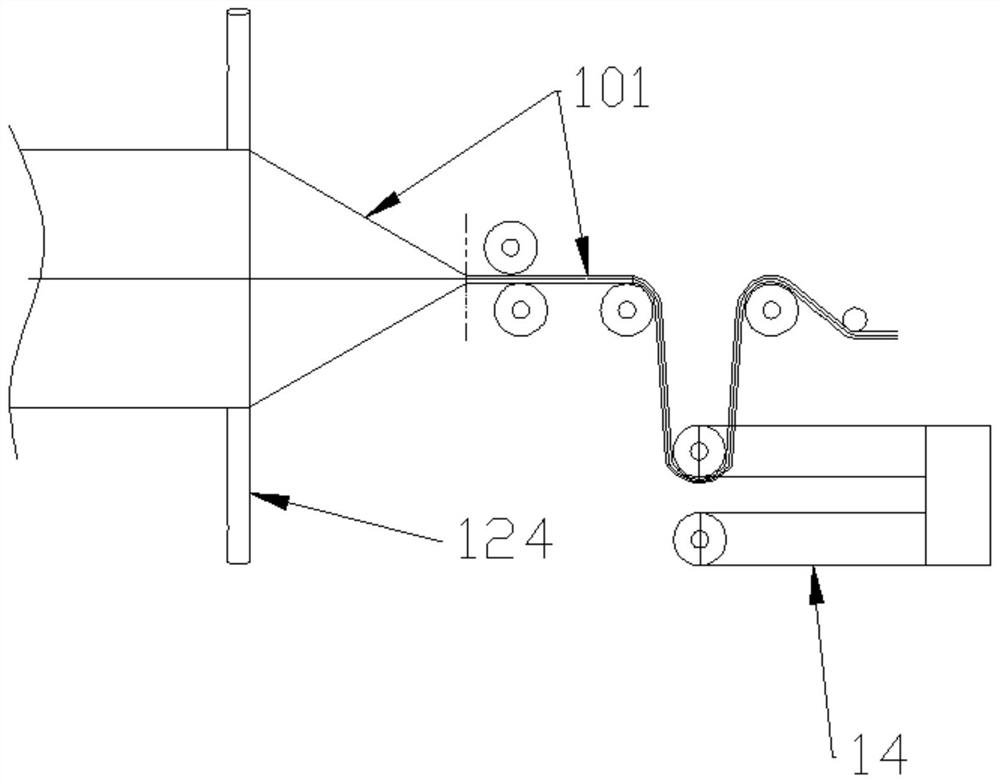

[0057] In this embodiment, the second floating roller 13 is located above the swing roller 14, and the swing roller 14 is connected through a swing arm

[0058] In this embodiment, the swing arm is also connected with a potentiometer, and the potentiometer is connected with a discharging motor. Using this advantage

[0059] In this embodiment, a photoelectric sensor 20 is provided between the shaping mechanism 6 and the punching mechanism 7. use this preference

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com