Locomotive brake resistor fault intelligent monitoring method

A technology of braking resistance and intelligent monitoring, applied in the direction of brakes, motor vehicles, brake components, etc., can solve problems such as unsolved problems, and achieve the effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

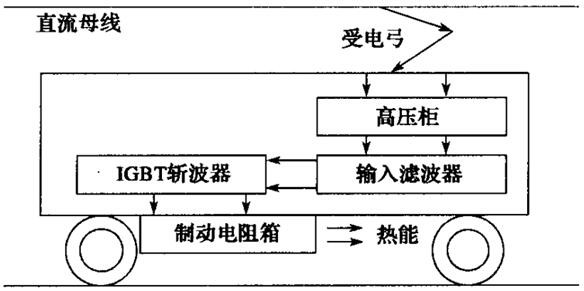

[0037] The working principle of the conventional locomotive braking resistor is attached figure 1 As shown; when the vehicle starts to brake with the braking resistor, the train will turn on the IGBT overvoltage chopping, and use the locomotive braking resistor to consume the regenerative energy of the IGBT chopping; and then use the fan to dissipate the heat of the locomotive braking resistor into the air; However, as the regenerative energy is dissipated on the braking resistor in the form of heat energy, the temperature of the resistor will gradually rise. It is necessary to monitor the braking resistor of the locomotive in real time to prevent the temperature of the braking resistor of the local locomotive from rising too fast, resulting in failure. Otherwise, it will seriously affect the safe operation of the vehicle traction system.

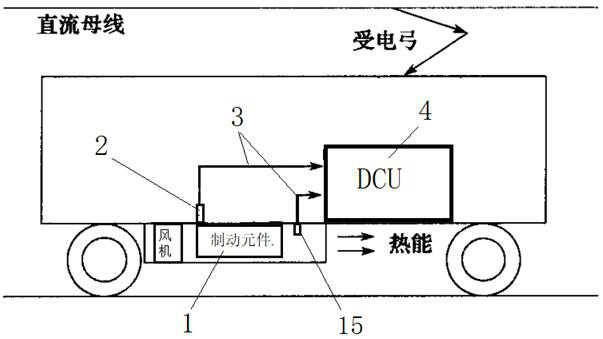

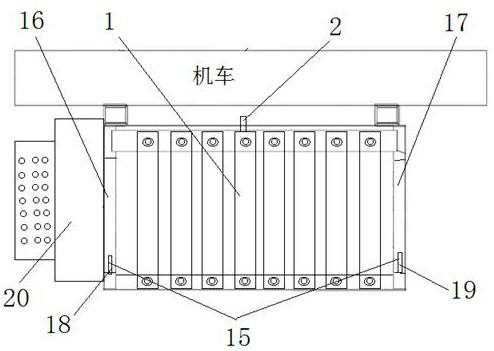

[0038] In order to obtain accurate braking resistor temperature, the present invention arranges a temperature sensor 2 in the body of the ...

Embodiment 2

[0052] The principle of the second embodiment is basically the same as that of the first embodiment, except that the specific structure and processing methods are different; an intelligent monitoring method for the failure of the braking resistor of the locomotive, through the braking resistor on the body surface of the braking resistor of the locomotive Install a temperature sensor, attach the temperature sensor to the body surface of the braking resistor, directly collect the temperature value on the surface of the braking resistor element, convert the collected temperature value into a temperature electrical signal, and send it to the traction control through the CAN bus The unit (DCU) performs intelligent identification and monitoring. At the same time, an air duct air temperature sensor is installed at the outlet or entrance of the ventilation duct of the braking resistor. The air temperature in the air duct is detected by the air duct air temperature sensor, and the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com