Automatic conveying system and method for instrument set sterilization

A technology of automatic transmission and packet transmission, applied in the field of medical equipment, can solve problems such as failure to detect in time, muscle strain of staff, equipment damage, etc., and achieve the effect of saving manpower and material resources, saving labor costs, and avoiding wrong selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

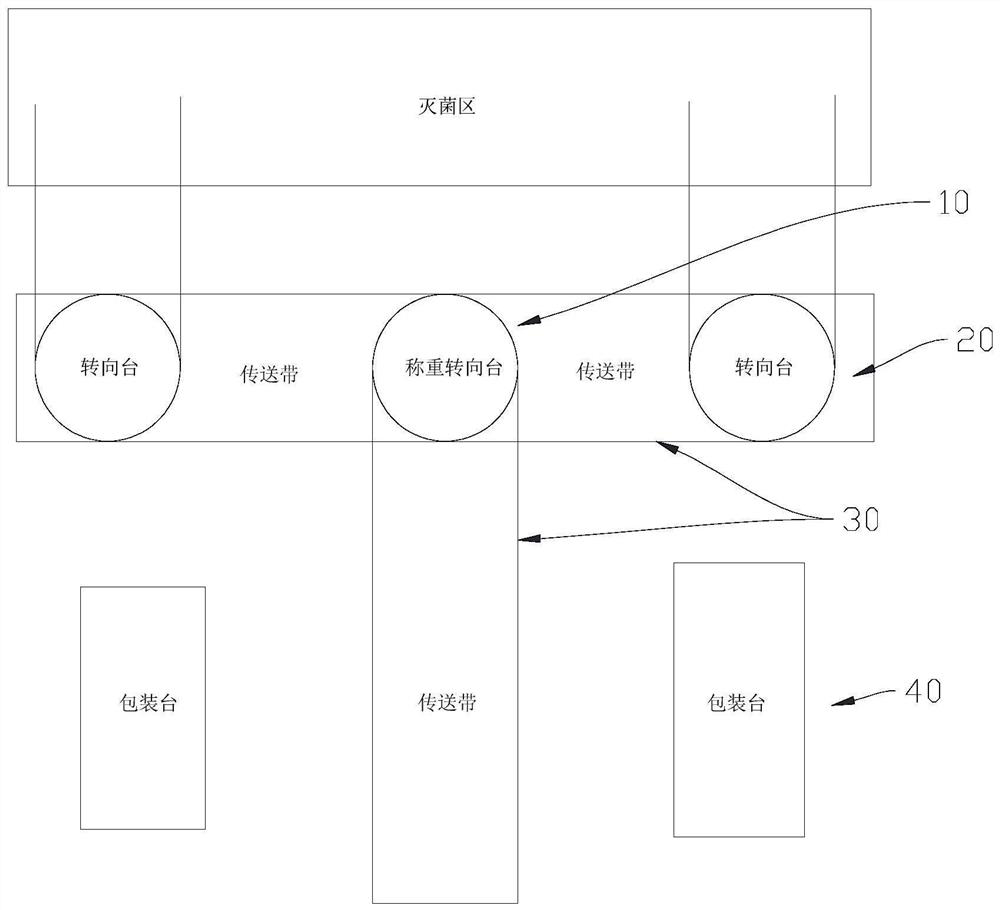

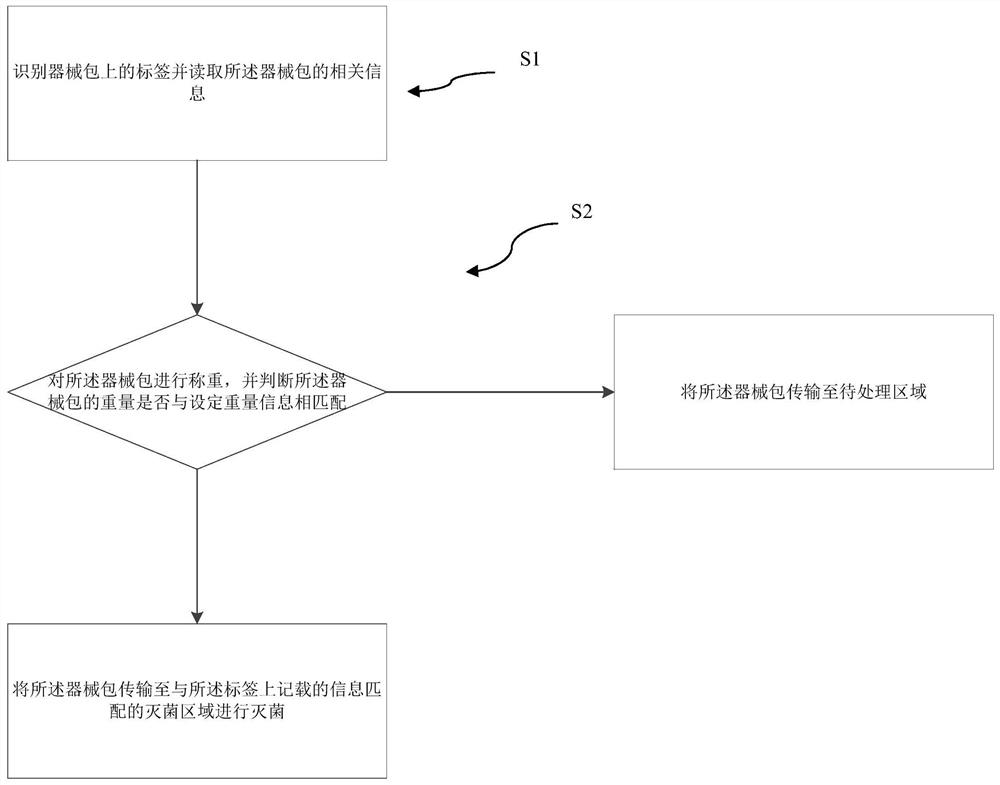

[0036] figure 1 Some preferred embodiments of the automatic instrument kit sterilization transfer system of the present invention are shown. The instrument package sterilization automatic transfer system can be used for automatic transmission of instrument packages, saving manpower and material resources, and can check the number of instruments in the instrument package in real time, avoiding the occurrence of wet packages of the instrument package, avoiding affecting the patient's operation process, and avoiding the selection of sterilization methods mistake. In some embodiments, a label can be set on the kit, and the label can record information about the kit, such as the type of kit, the weight of the kit, the steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com