Polyethylene laser marking master batch as well as preparation method and application thereof

A laser marking and polyethylene technology, applied in the field of polymer materials, can solve the problems of poor laser marking performance, and achieve the effect of excellent laser sensitivity and excellent laser marking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

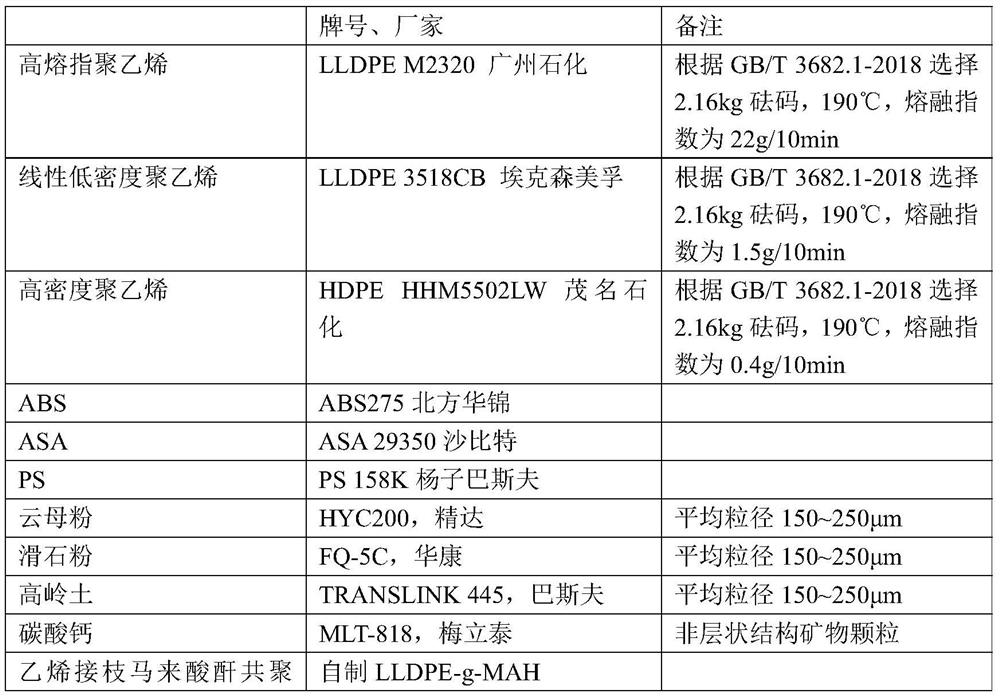

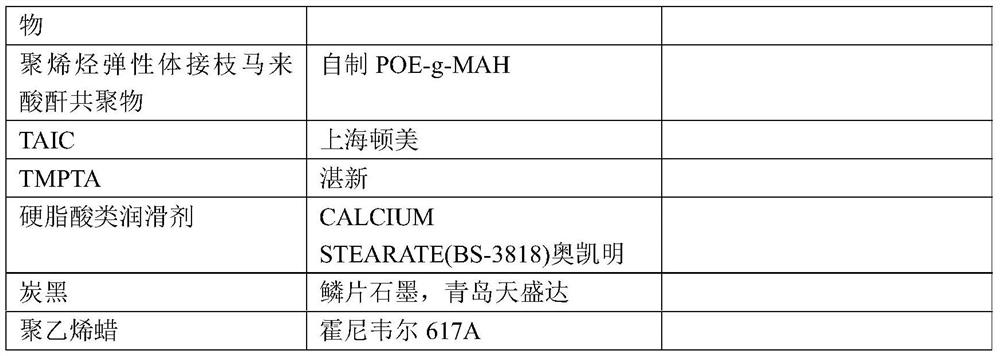

[0061] Embodiments 1 to 8 provide polyethylene laser marking masterbatches, which are respectively denoted as masterbatches A to H. The contents of each component of the polyethylene laser marking masterbatches are shown in Table 1.

[0062] Each component content (weight part) in the embodiment 1~8 of table 1

[0063]

[0064] The preparation method of the polyethylene laser marking masterbatch of embodiment 1~8 is:

[0065] Mix polyethylene, polystyrene-based copolymers, layered mineral particles, compatibilizers, cross-linking sensitizers, and lubricants into an extruder, melt extrude, cool, and granulate to obtain polyethylene laser marking Standard masterbatch.

Embodiment 9~20

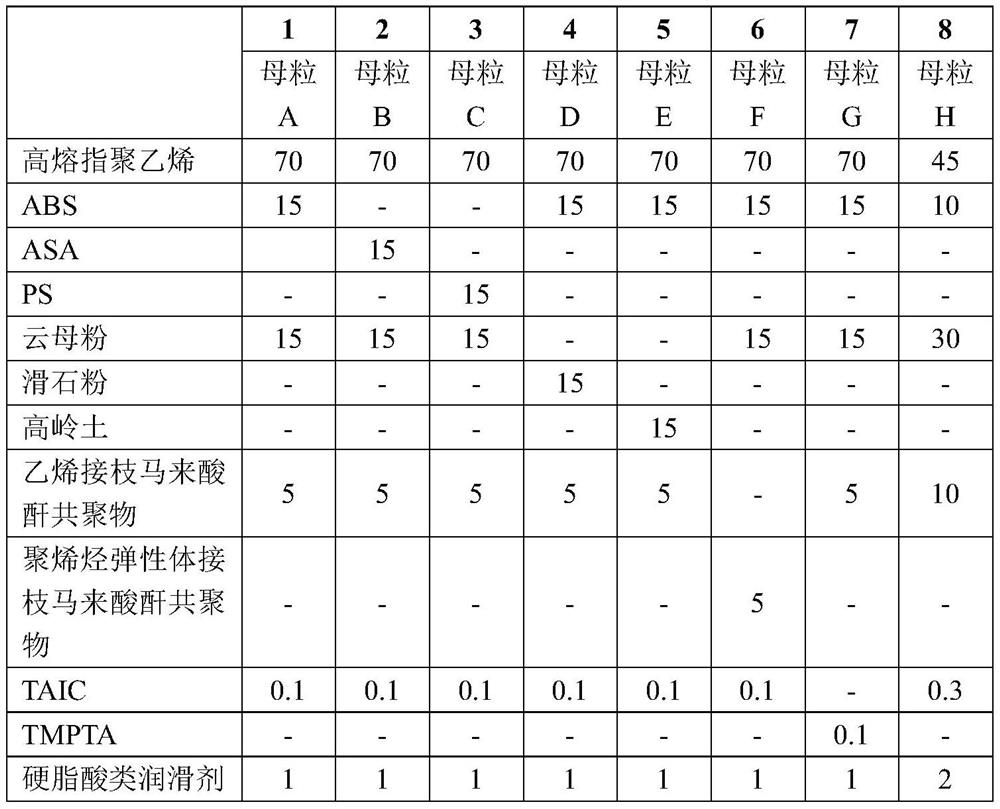

[0067] Embodiments 9-20 provide a polyethylene material for an optical cable sheath, and the content of each component of the polyethylene material for an optical cable sheath is shown in Table 2.

[0068] Each component content (weight part) in the embodiment 9~20 of table 2

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com