Macromolecule/modified organic montmorillonite laser marking material, and preparation method and antibacterial application thereof

A technology of organic montmorillonite and laser marking, applied in the field of new polymer materials, to achieve the effect of environmental protection application, low cost and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

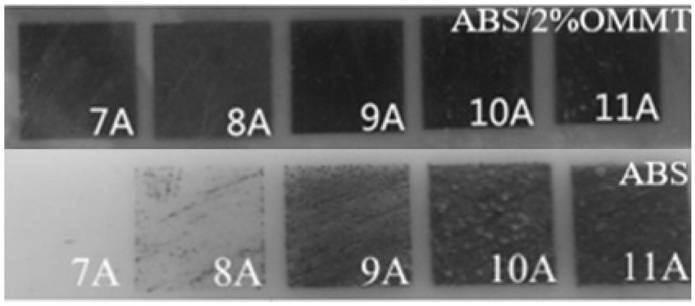

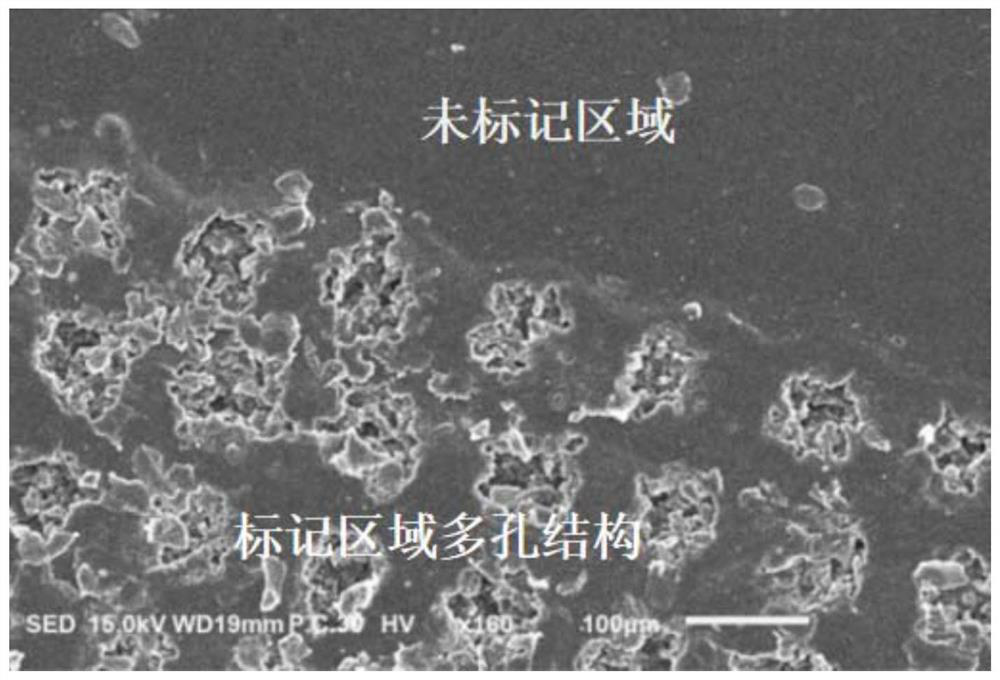

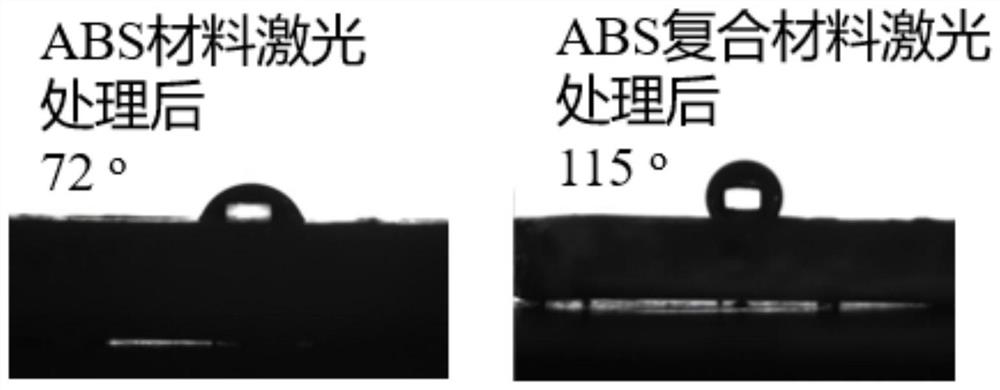

Method used

Image

Examples

Embodiment 1

[0035] Preparation of polymer / modified organic montmorillonite composites:

[0036](1) Take 54mL of methanol and 6mL of water in a 100mL flask and stir evenly, then add tetrabutyl titanate coupling agent respectively, the concentration is 1-4vol.%), then adjust the pH to 5.5 with glacial acetic acid, Heat in an oil bath at 56°C, react at a constant temperature for 1.5h, then raise the temperature to 85°C, add 1g of montmorillonite (sodium-based montmorillonite, particle size range 10-50nm), stir and react at a constant temperature for 2h, wash with methanol, filter with suction, Dry at 60°C to obtain a coupling agent-modified montmorillonite;

[0037] Use surfactant to modify montmorillonite, add 1g of coupling agent modified montmorillonite to 100mL round bottom flask, add 25mL water to stir and disperse evenly, slowly add cetyl trimethyl bromide at 70℃ Ammonium CTAB surfactant with a concentration of 7.5 mg / mL was reacted for 6 hours, washed with ethanol and water until no ...

Embodiment 2

[0045] Compared with Example 1, the difference between Example 2 is that nano zinc oxide particles are added therein.

[0046] Preparation of polymer / modified organic montmorillonite / zinc oxide composite:

[0047] (1) The preparation of organically modified montmorillonite, the difference is that the silane coupling agent KH550 is used, and the others are the same as in Example 1;

[0048] (2) 35 parts of organically modified montmorillonite, 20 parts of antibacterial nano-zinc oxide (ZnO, 10nm), 45 parts of polystyrene and 0.5 part of antioxidant, using a torque rheometer for blending operation, the setting temperature is 200°C, the rotation speed is 30r / min, and the blending time is 6min, so that the modified montmorillonite, nano-zinc oxide, antioxidant and polystyrene are fully melted and uniform, and then tableted and granulated to obtain laser masterbatch.

[0049] (3) Polymer / modified organic montmorillonite / zinc oxide composite material was prepared by melt blending m...

Embodiment 3

[0060] Preparation of polymer / modified organic montmorillonite / zinc oxide composite:

[0061] (1) The preparation of organically modified montmorillonite, the difference is that the silane coupling agent KH560 is used, and the others are the same as in Example 1;

[0062] (2) 35 parts of organically modified montmorillonite, 20 parts of antibacterial nano zinc oxide (ZnO, 15nm), 45 parts of polystyrene and 0.5 part of antioxidant, use torque rheometer to carry out blending operation, set temperature as 205°C, the rotation speed is 35r / min, and the blending time is 5min, so that the modified montmorillonite, nano-zinc oxide, antioxidant and polystyrene are fully melted and uniform, and then tableted and granulated.

[0063] (3) Prepare polymer / modified organic montmorillonite / zinc oxide composite material by melt blending method, 100 parts of high-density polyethylene, 1 part of masterbatch with laser marking and antibacterial properties, and 0.5 part of antioxidant . The org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com