Bridge inspection vehicle device and method capable of self-adapting to track installation errors

A bridge inspection vehicle and installation error technology, which is applied to bridges, tracks, bridge parts, etc., can solve the problems of out-of-synchronization, wear and tear, and track and track jamming of the inspection vehicle, so as to avoid the driving trolley from being stuck on the track and ensure the structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

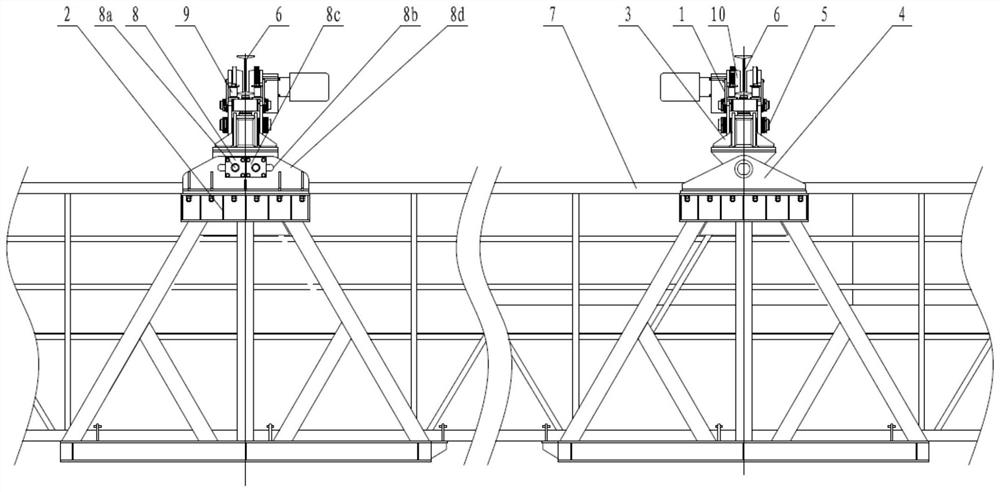

[0030] A bridge inspection vehicle device for adaptive rail installation errors, please refer to the attached figure 1 As shown, it includes walking tracks 6 arranged on the left and right sides of the bottom of the bridge, the driving trolley 1 suspended on the walking track 6, the driving trolley 1 is provided with walking wheels 10, and the driving trolley 1 passes through the walking wheels 10 and the walking The track 6 forms a support and can roll forward or backward along the walking track 6. The lower end of the driving trolley 1 is fixedly connected with the mast 2, and the mast 2 is connected with the vehicle frame 7. There is also a track installation error between the driving trolley 1 and the mast 2. Regulating mechanism.

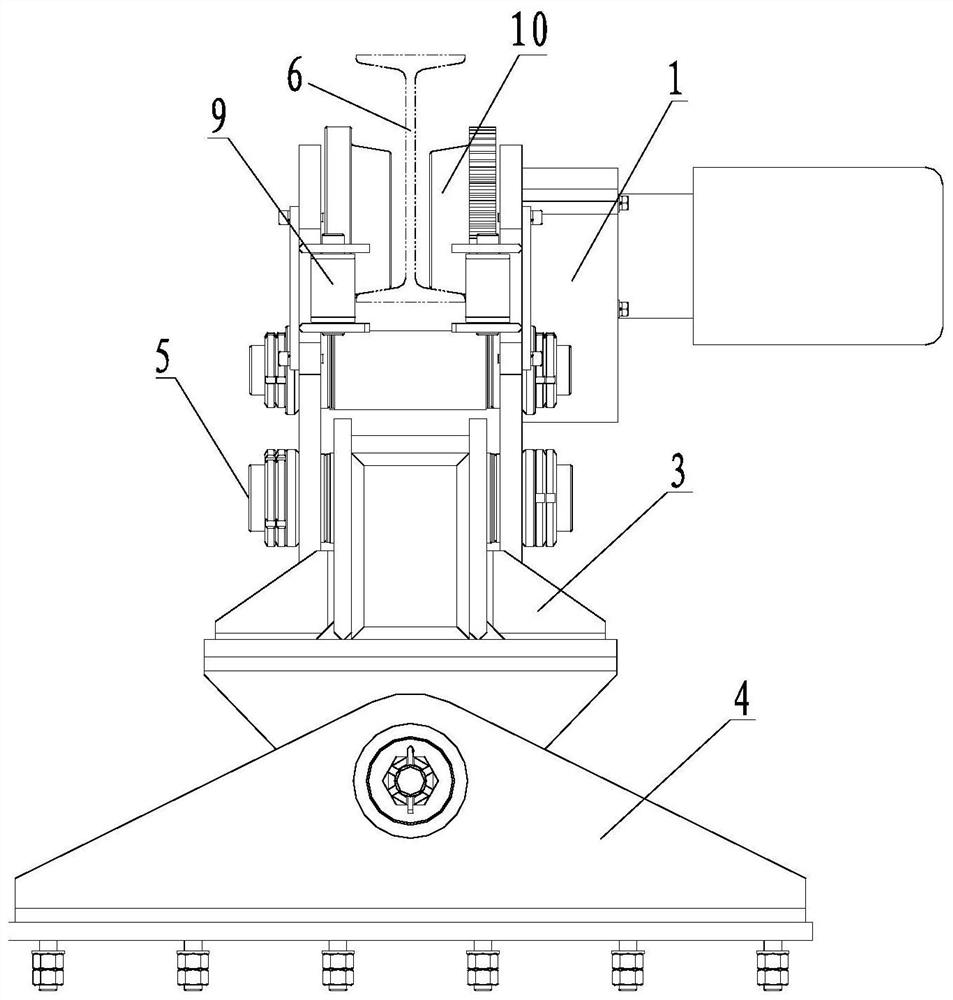

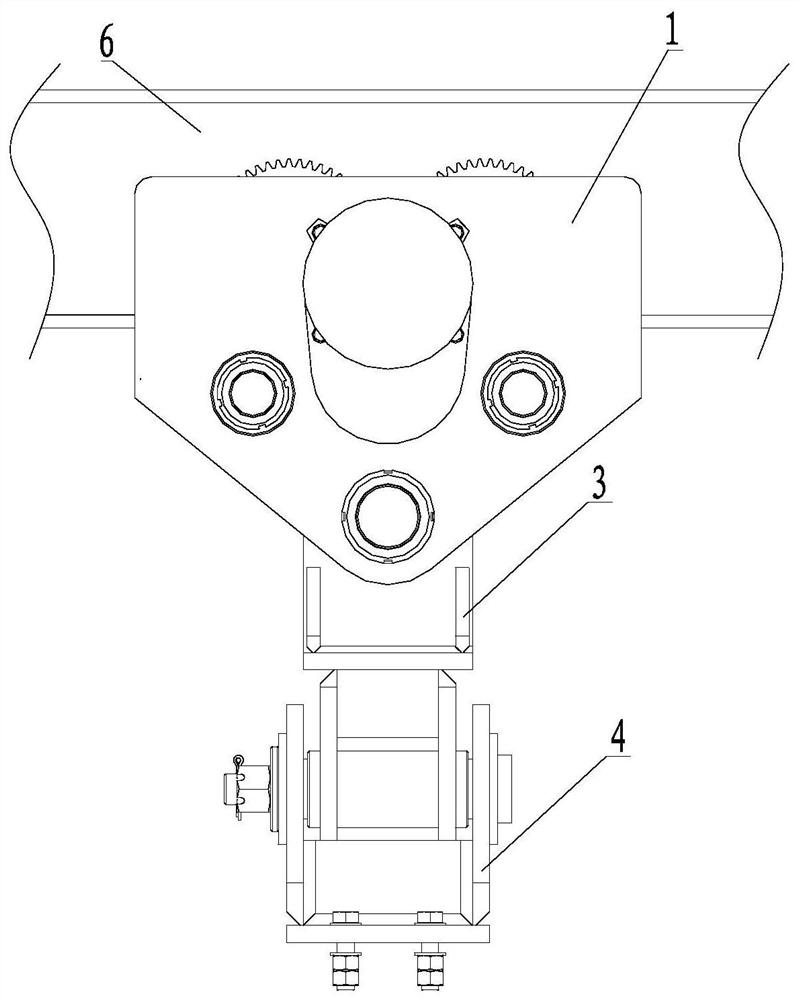

[0031] For more details, please refer to the attached figure 2 - attached Figure 5 As shown, the track error adjustment mechanism includes an upper cross hinge 3 hinged on the driving trolley 1 on the left and right sides, and the upper cro...

Embodiment 2

[0033] A bridge inspection vehicle device for adaptive rail installation errors, please refer to the attached figure 1 As shown, it includes walking tracks 6 arranged on the left and right sides of the bottom of the bridge, the driving trolley 1 suspended on the walking track 6, the driving trolley 1 is provided with walking wheels 10, and the driving trolley 1 passes through the walking wheels 10 and the walking The track 6 forms a support and can roll forward or backward along the walking track 6. The lower end of the driving trolley 1 is fixedly connected with the mast 2, and the mast 2 is connected with the vehicle frame 7. There is also a track installation error between the driving trolley 1 and the mast 2. Regulating mechanism.

[0034] The difference between this embodiment and Embodiment 1 is that please continue to refer to the attached figure 2 - attached Figure 5 As shown, in this embodiment, the rail installation error adjustment mechanism also includes a lowe...

Embodiment 3

[0037] A bridge inspection vehicle device for adaptive rail installation errors, please refer to the attached figure 1 As shown, it includes walking tracks 6 arranged on the left and right sides of the bottom of the bridge, the driving trolley 1 suspended on the walking track 6, the driving trolley 1 is provided with walking wheels 10, and the driving trolley 1 passes through the walking wheels 10 and the walking The track 6 forms a support and can roll forward or backward along the walking track 6. The lower end of the driving trolley 1 is fixedly connected with the mast 2, and the mast 2 is connected with the vehicle frame 7. There is also a track installation error between the driving trolley 1 and the mast 2. Regulating mechanism.

[0038] In this embodiment, a guide block 9 is provided between the drive trolley 1 and the running track 6, and the guide block 9 can provide sufficient lateral stiffness for the drive trolley 1, so that the traveling wheels 10 only bear vertical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap