Construction method for floating transportation undocking installation of dock gate

A construction method and dock door technology, applied in the directions of transportation and packaging, artificial islands, dry docks, etc., can solve the problems of large volume, heavy weight, and difficult dock doors to be floated out of the dock, so as to ensure accuracy, reduce weight, guarantee The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

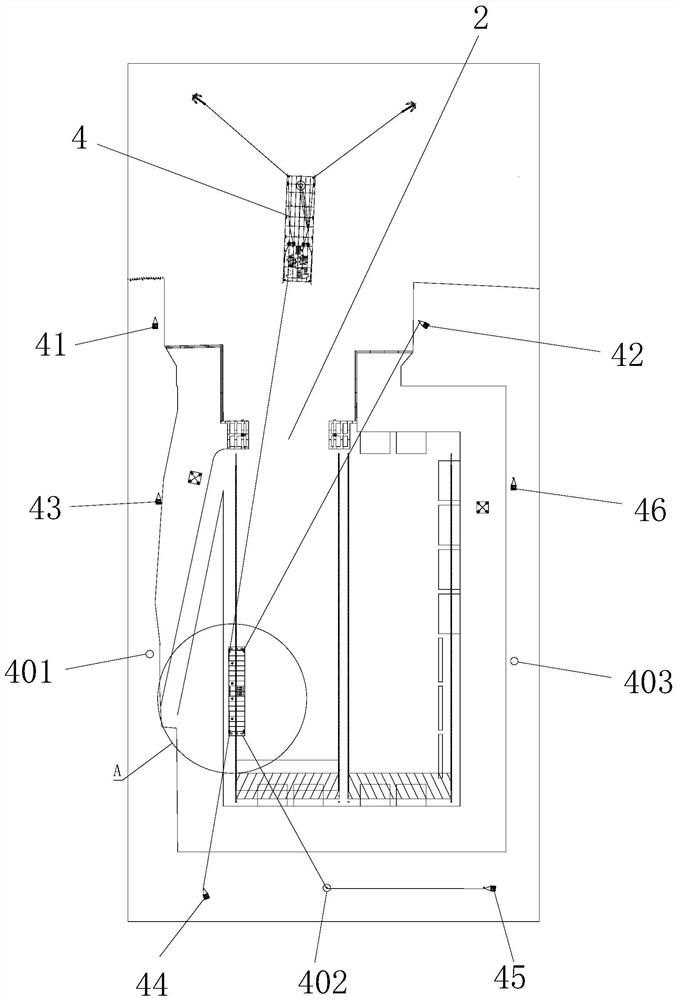

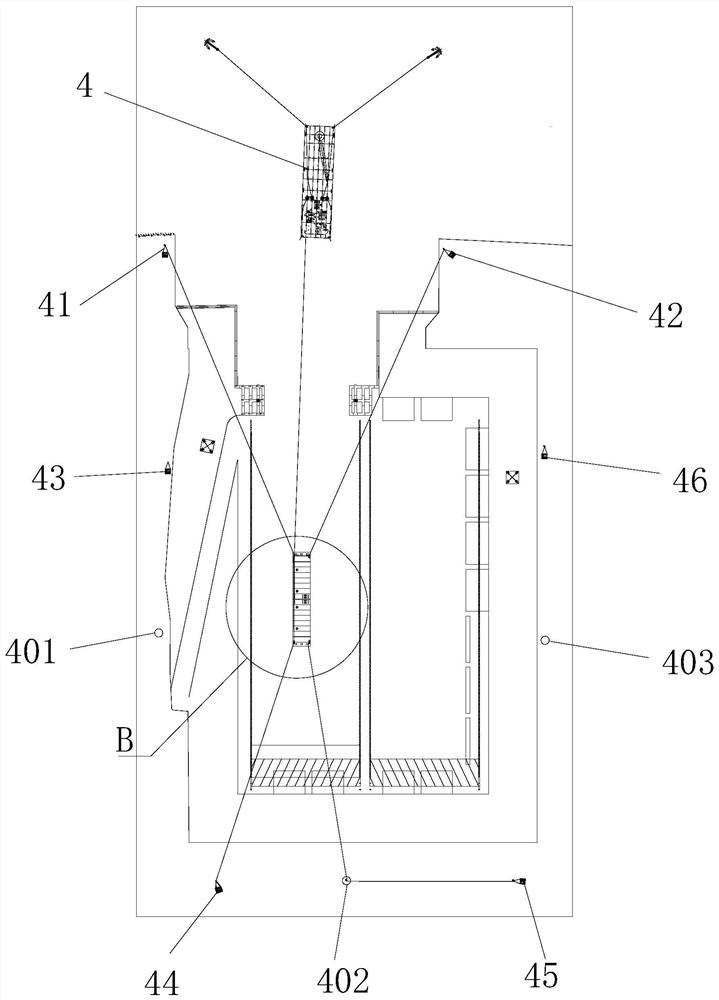

[0074] This embodiment 1 provides a construction method for the dock door to be floated out of the dock for installation. It should be noted that when implementing this embodiment 1, the dock door 1 should be located at the storage position in the dock. Present embodiment 1 specifically comprises the following steps:

[0075] S1, extracting the accumulated water in the water storage chamber to float the dock door 1;

[0076] In this embodiment 1, the dock door 1 has a water storage cavity, and water can be poured into the water storage cavity to facilitate the sinking of the dock door 1, that is, to make the dock door 1 sit on the bottom by pressing water, and to facilitate storage of the dock door. 1. It is possible to reduce the weight of the dock door 1 by pumping out the accumulated water in the water storage chamber, so as to facilitate the floating of the dock door 1 and facilitate the floating transportation of the dock door 1. In the present embodiment 1, the accumula...

Embodiment 2

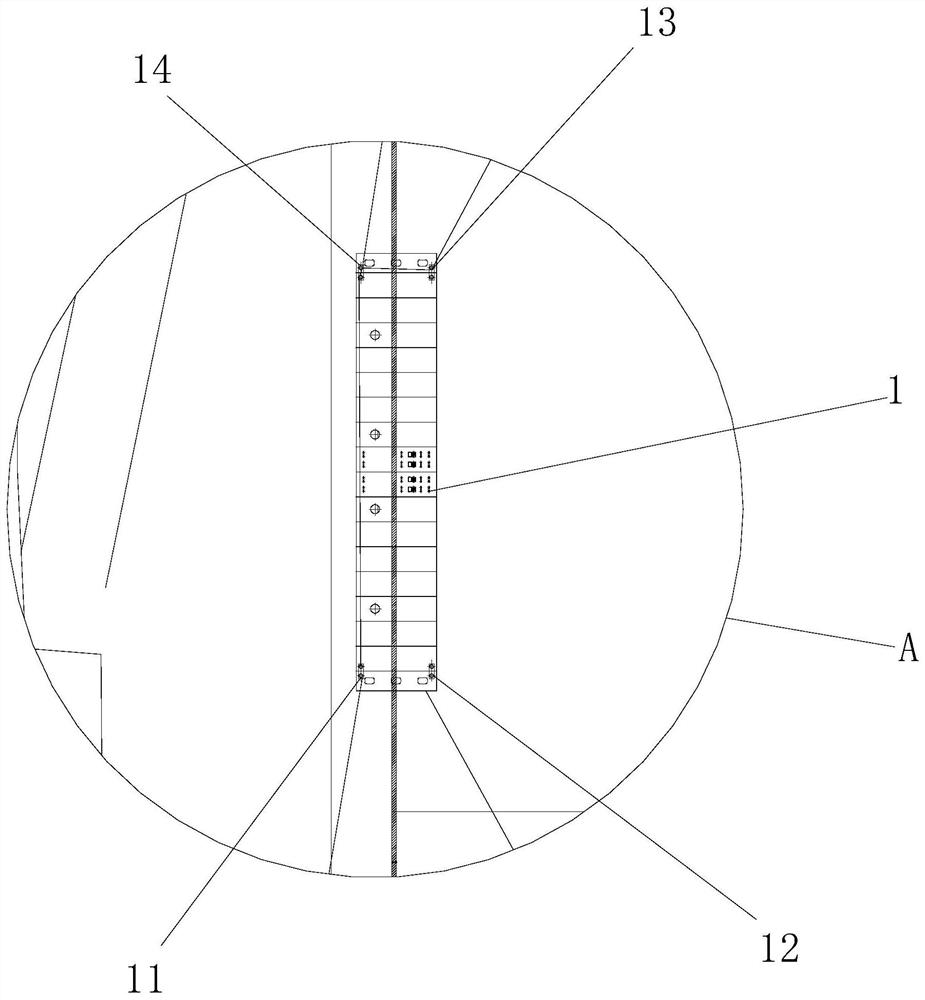

[0103] Embodiment 2 is the specific structure of the dock door in Embodiment 1.

[0104] The dock door 1 of the present embodiment 2 includes a steel frame 5; as Figure 16 to Figure 18 As shown, the steel frame 5 is preferably cuboid, and the steel frame 5 is provided with a bottom plate 51, a top plate 52, a first panel 53, a second panel 54, a first side plate 55 and a second side plate 56; the bottom plate 51 and the top plate 52 are opposite Set, the first panel 53 and the second panel 54 are set oppositely, the first side plate 55 and the second side plate 56 are set oppositely, the bottom plate 51, the top plate 52, the first panel 53, the second panel 54, the first side plate 55 and The second side plate 56 together constitutes the steel frame 5; specifically, the bottom plate 51, the top plate 52, the first panel 53, the second panel 54, the first side plate 55 and the second side plate 56 are spliced by several steel plates. The steel frame 5 is provided with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com