Steel structure workshop framework

A technology for steel structures and workshops, which is applied to building components, building structures, and earthquake resistance, and can solve problems such as the inability to adjust according to needs and the inability to install beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

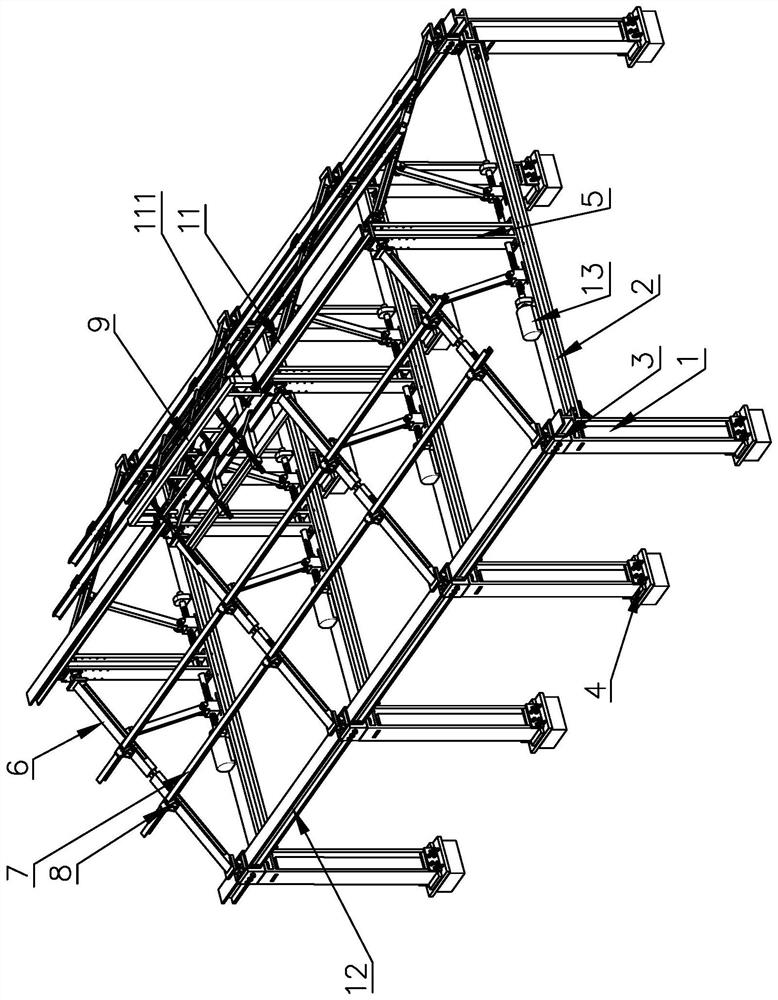

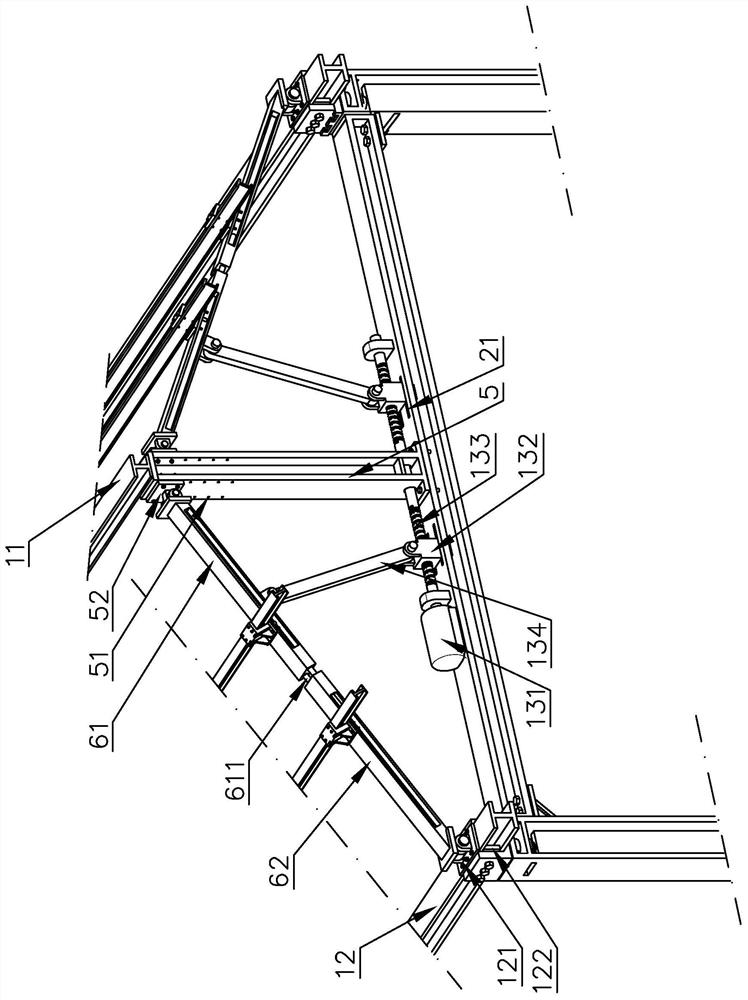

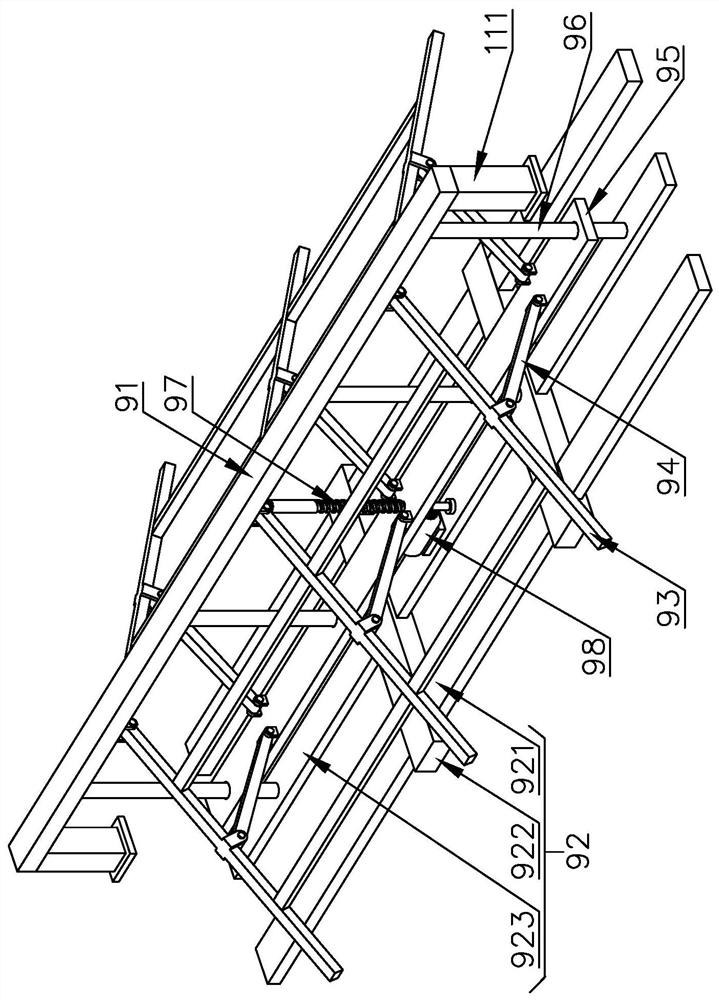

[0034] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0035] A skeleton of a steel structure factory building, comprising a first column 1, a transverse beam 2, a first connecting seat 3, a shock-absorbing fixing seat 4, a second column 5, an oblique beam 6, purlins 7, an adjusting fixing seat 8, a skylight 9, The first longitudinal beam 11, the second longitudinal beam 12, and the adjustment mechanism 13; the first connecting seat 3 is fixed on the top of the first column 1, and the shock-absorbing fixing seat 4 is fixed on the bottom of the first column 1; the two ends of the transverse beam 2 are fixed Connect the first column 1; one end of the second column 5 is fixedly connected to the transverse beam 2; both ends of the second longitudinal beam 12 are connected to the first connecting seat 3; Column 5; Adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com