Efficient chip removal system for plasma rock breaking

A plasma and rock-breaking technology, applied in construction and other directions, can solve the problems of reducing rock-breaking efficiency, unable to achieve high-speed rock-breaking, etc., and achieve the effects of improving drilling efficiency, efficient chip removal, and simple drill bit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

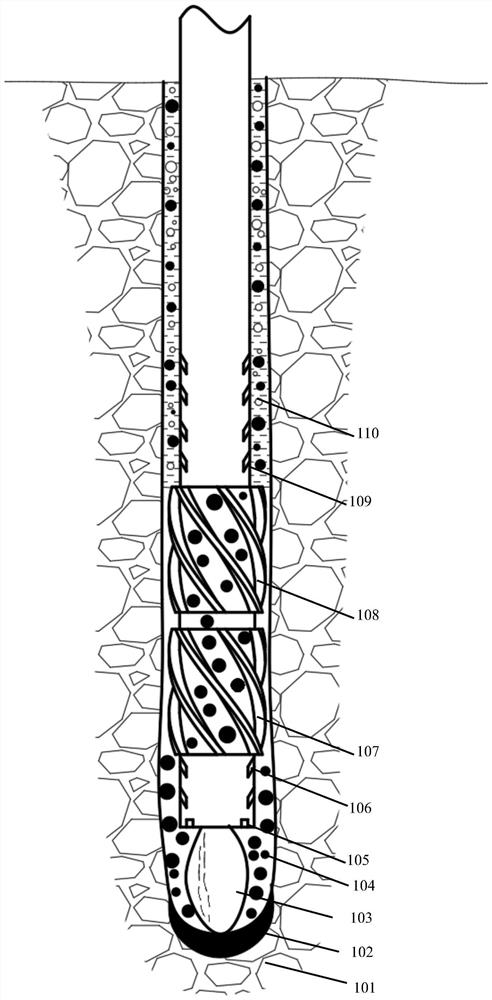

[0008] Such as figure 1 As shown, in the process of plasma rock breaking, the end of the plasma drill bit ejects a high-temperature and high-speed plasma arc 103, the high-temperature plasma arc 103 melts the formation 101 in the working area, and forms a molten magma pool 102 at the bottom of the well; There are multiple high-pressure gas nozzles 105, and the high-pressure gas nozzles 105 eject high-pressure gas intermittently, and the high-pressure gas is directly injected onto the magma pool 102, and the magma pool 102 is impacted into molten rock particles 104; multiple rising gas nozzles 106 are distributed on the drill bit , the outlet of the rising gas spout 106 is upward, and the rising gas spout 106 continuously ejects upward high-speed gas; the upward high-velocity gas blows the rock melting particles 104 upwards; at the high-pressure gas spout 105, the intermittent high-pressure gas and the rising gas spout 106 are sprayed Under the action of continuous high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com