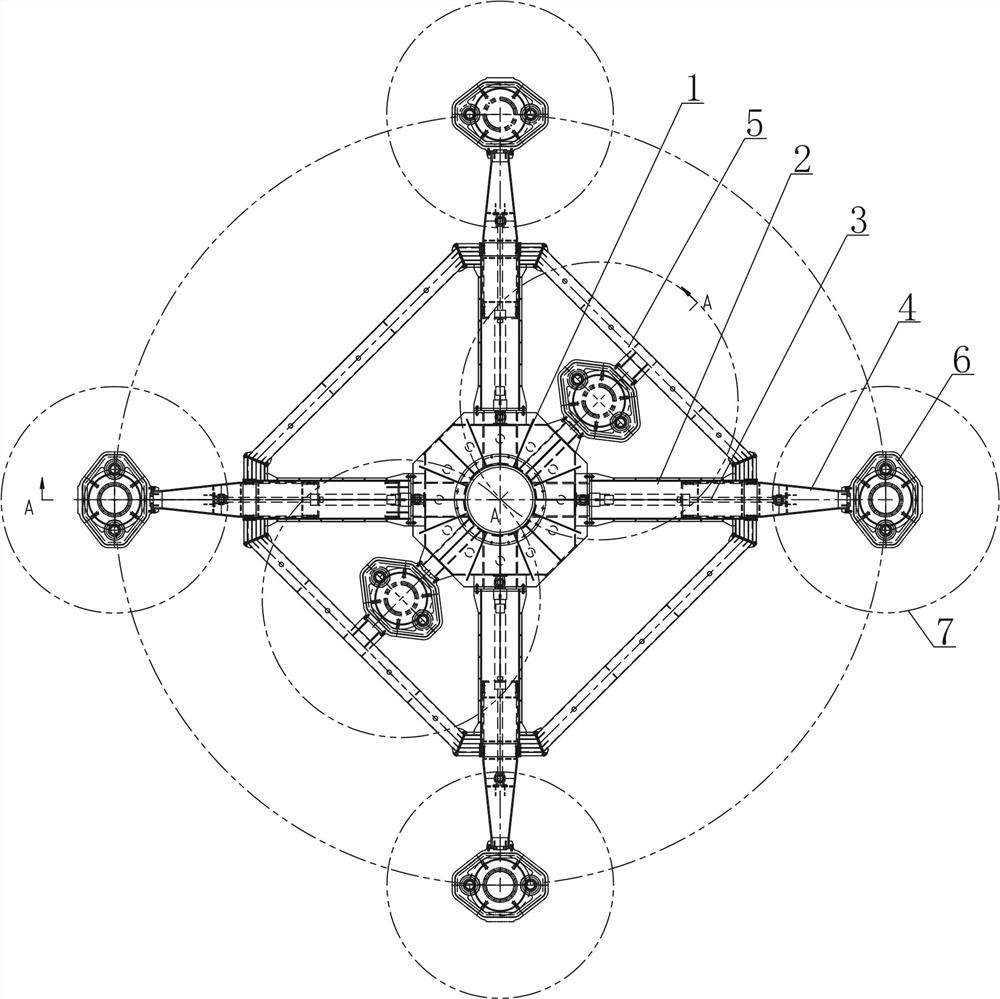

Telescopic revolution rack for ultra-large-diameter full-section shaft drilling machine

A super-large-diameter, full-section technology, applied to shaft equipment, sinking, drilling equipment, etc., can solve problems such as huge excavation equipment for super-large-diameter shafts, large excavation engineering, and difficulties in manufacturing, assembly, transportation, and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

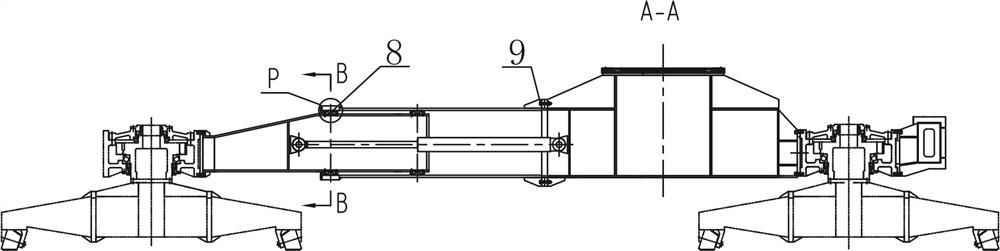

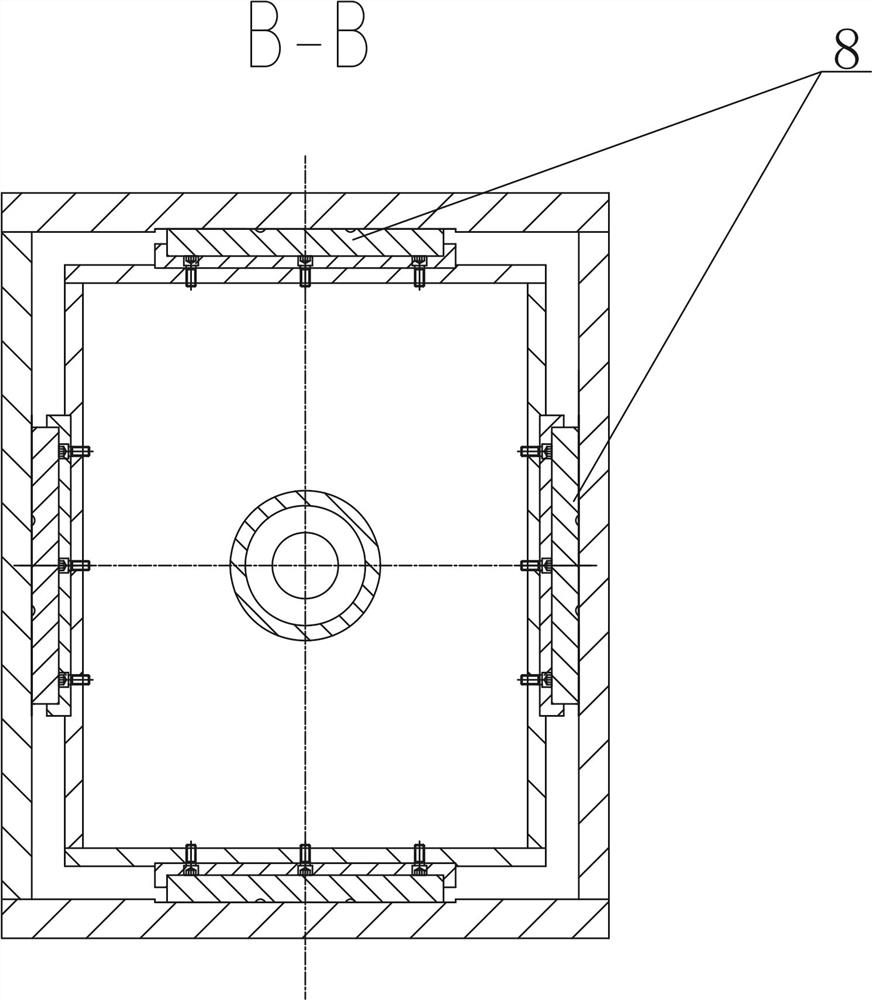

[0024]JoinFigure 1-4 , A telescopic mutual rack for large diameter full-section shaft rig is used in detail, including an intermediate frame 1, a mutual beam 2, a telescopic beam 4, a connecting beam 5, and a driver box 6, an intermediate frame 1 vertical setting, Four uniform uniformly spaced uniform intervals along the intermediate frame 1 is provided with a radial-shaped beam 2, and one end of the male rotor beam is connected to the intermediate frame 1 by a connecting bolt, and the other end of the mutant beam 2 is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap