An oil-pneumatic spring base assembly integrating a vehicle height sensor and a valve group

A technology of oil-gas spring and base assembly, applied in the direction of spring, spring/shock absorber, shock absorber, etc., can solve the problems of high process requirements, complex structure, many installation steps, etc., to improve reliability and accuracy, optimize The effect of using the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific examples illustrate the present invention in further detail.

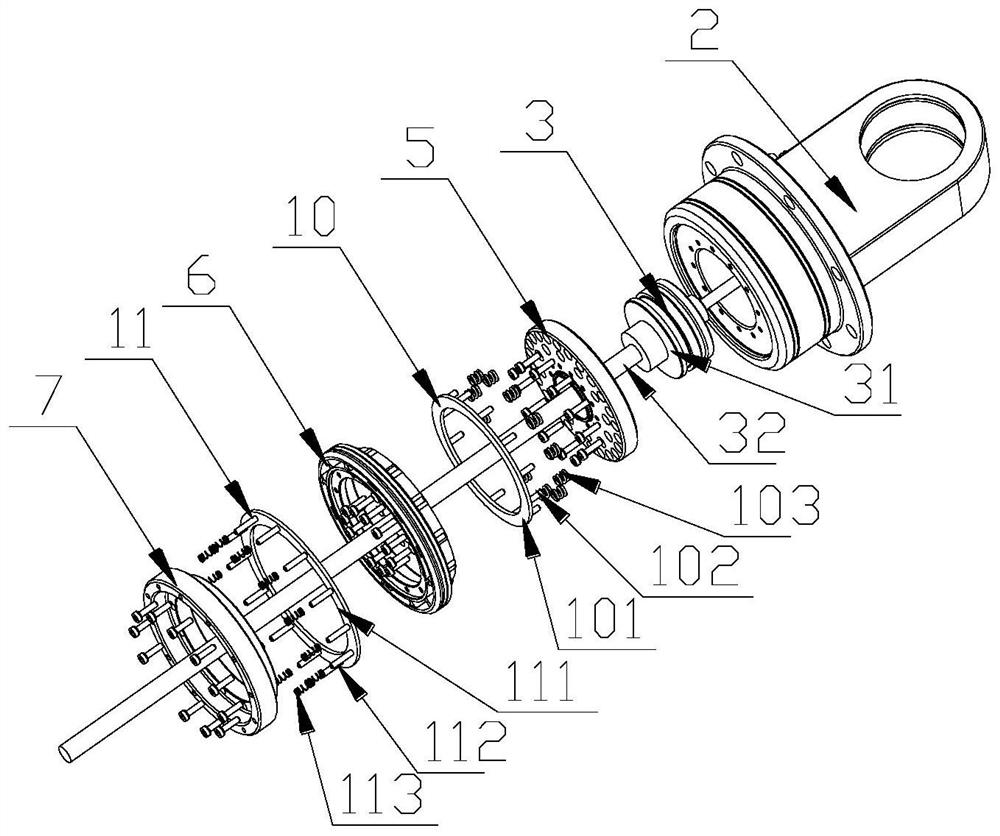

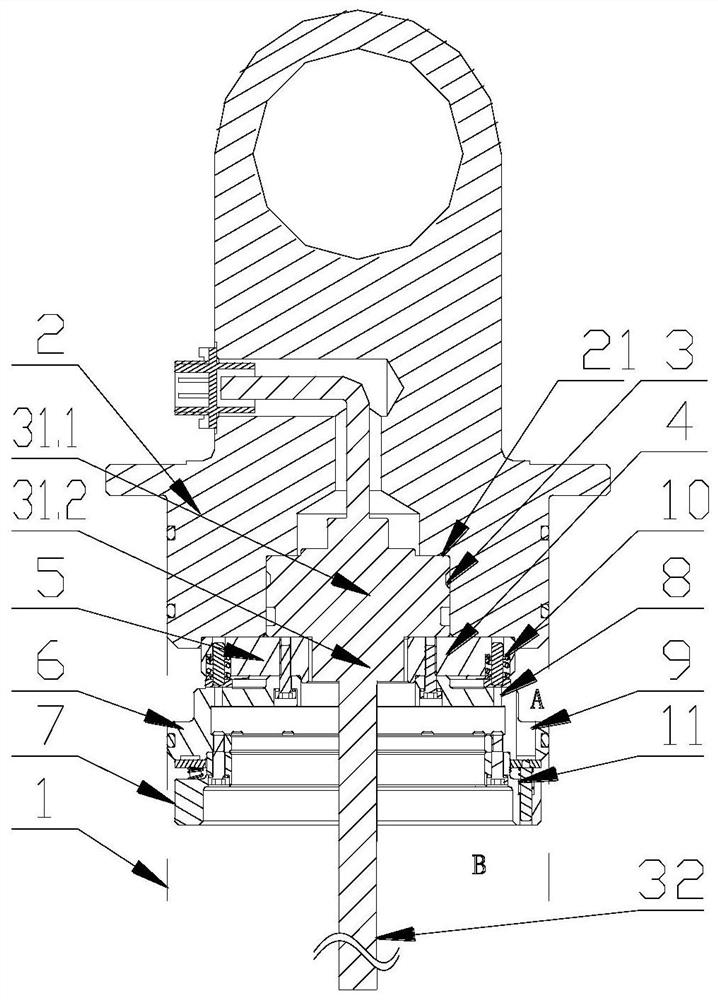

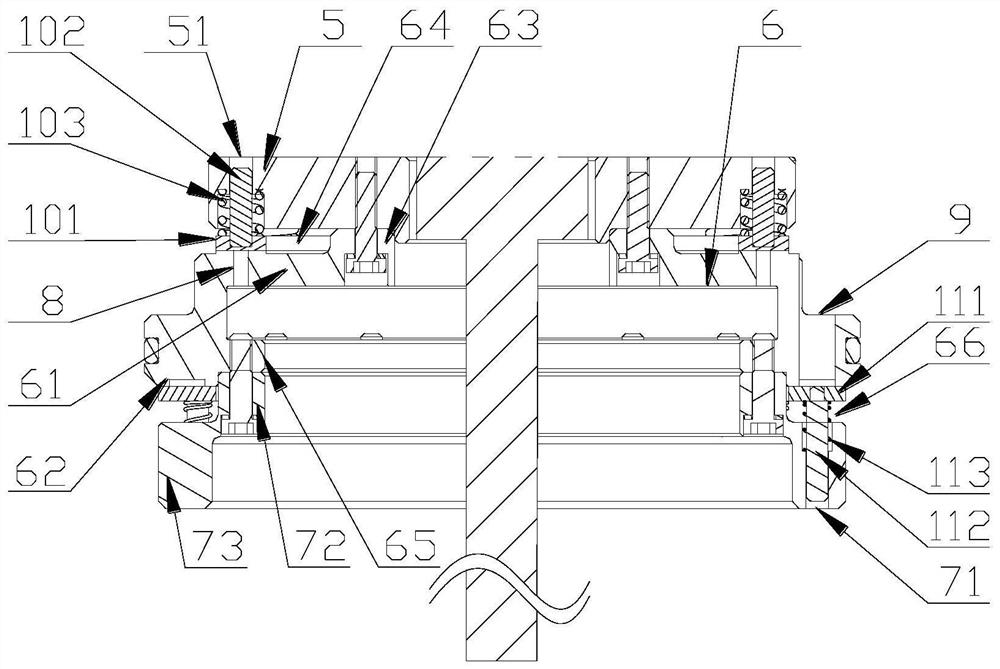

[0036] Such as Figure 1-3 As shown, the present invention provides an oil-pneumatic spring base assembly integrating a vehicle height sensor and a valve group, including a base 2 sealed and arranged on the upper end of the cylinder 1, and a vehicle height sensor 3 and valves arranged in the cylinder 1 Group 4, the vehicle height sensor 3 includes an electronic head 31 connected up and down and a sensing rod 32, the electronic head 31 is sealed and installed on the base 2, and the sensing rod 32 passes through the valve group 4 downward; the valve group 4 includes the same The ring-shaped upper pressure plate 5, valve seat 6, and lower pressure plate 7 connected by the shaft, the upper pressure plate 5 is fixedly connected with the base 2, the valve seat 6 is circumferentially sealed with the cylinder barrel 1 and the valve seat 6 is provided with a valve group The unloading through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com