Sucker type fixing seat for camera equipment and conversion assembly of sucker type fixing base

A technology for converting components and fixing parts, which is applied in the direction of suction cups, connecting components, supporting machines, etc. It can solve the problems of troublesome installation and removal of cameras, missing the best opportunity for shooting, time-consuming and laborious installation and removal of cameras, etc., and achieves simple structure, Simple and fast installation and disassembly, improving simplicity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objects and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be clear that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

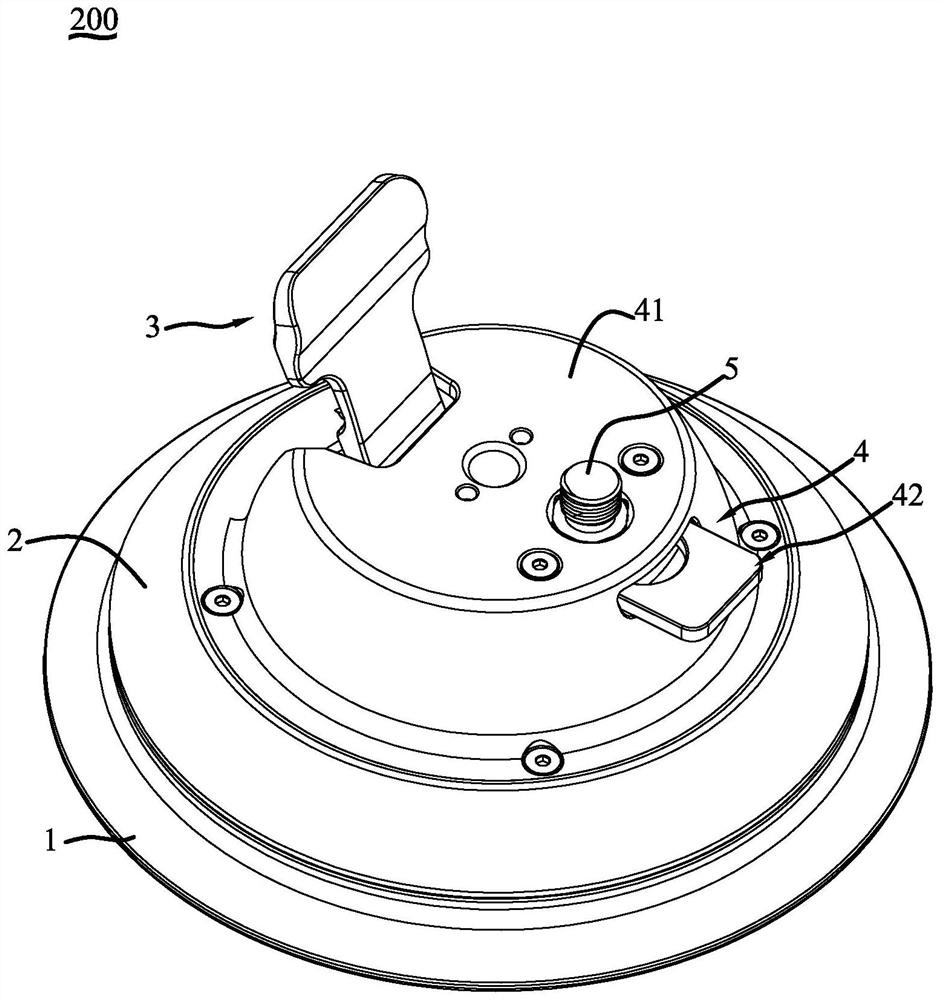

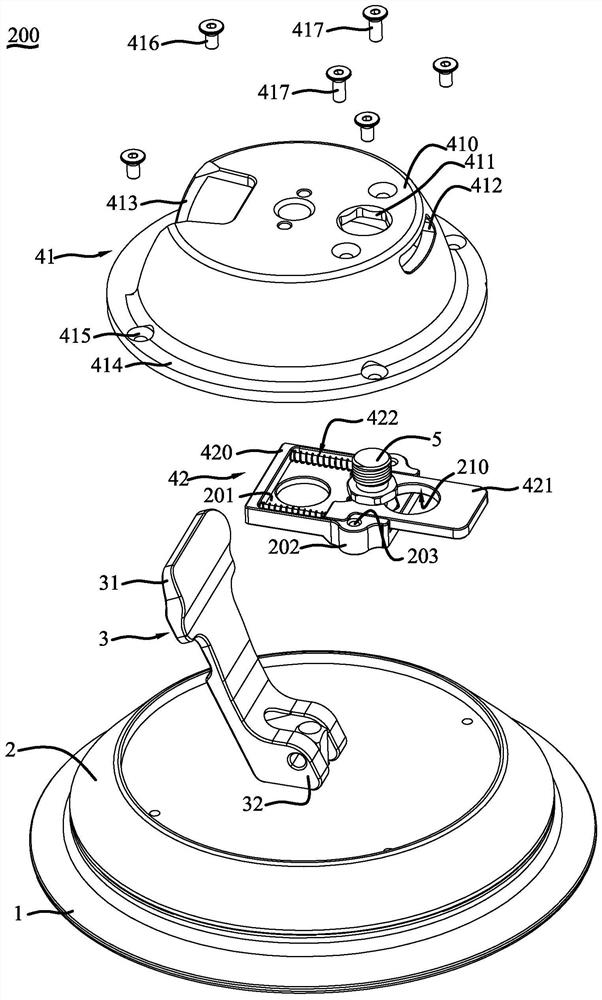

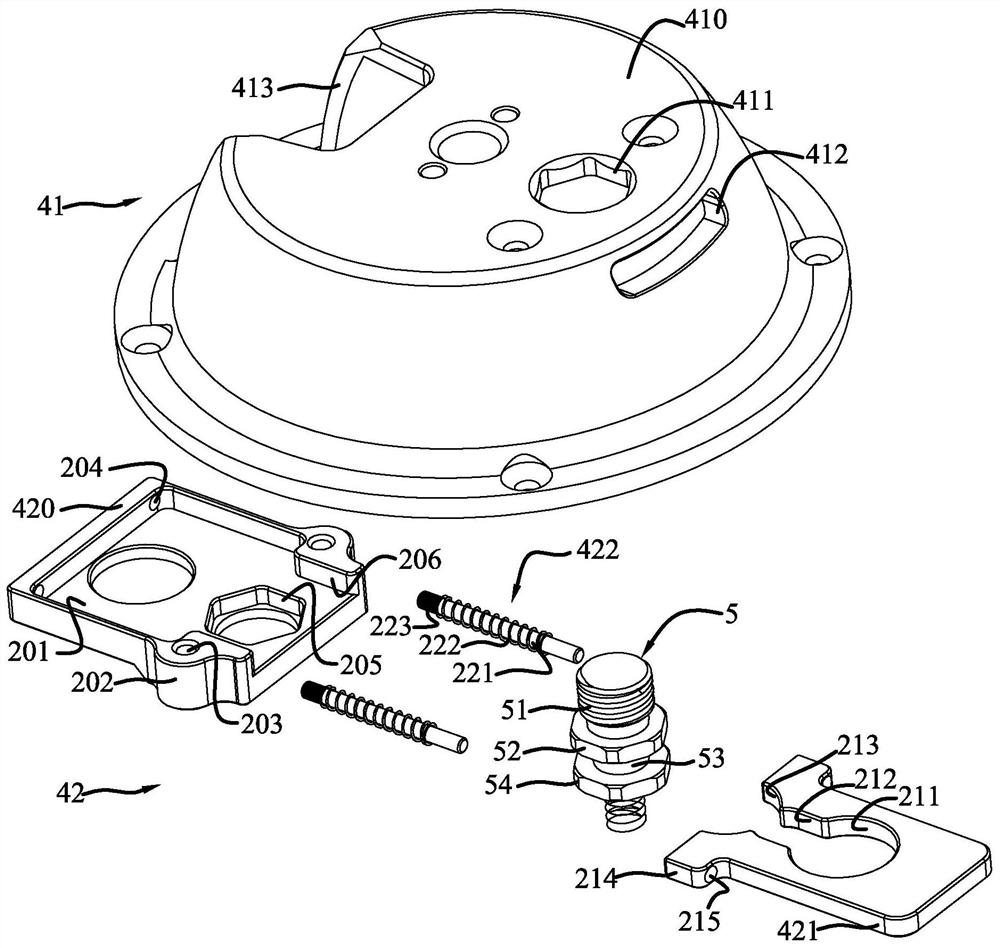

[0020] Also refer to figure 1 and figure 2 , the suction cup type fixing base 200 for camera equipment according to an embodiment of the present invention includes a suction cup 1, a base 2 covering the suction cup 1, and a lifting member 3 passing through the base 2 and connected to the suction cup 1 , and the conversion assembly 4 connected to the base 2 . In this embodiment, the lifting member 3 is configured in the form of a toggle, which includes a handle 31 for the user to operate to rotate and a biasing portion 32 disposed at a lateral end of the handle 31 . The thickness of the offset portion 32 in a direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com