Magnetic levitation turntable with fifteen degrees of freedom and applied to semi-physical simulation platform

A semi-physical simulation, degree of freedom technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

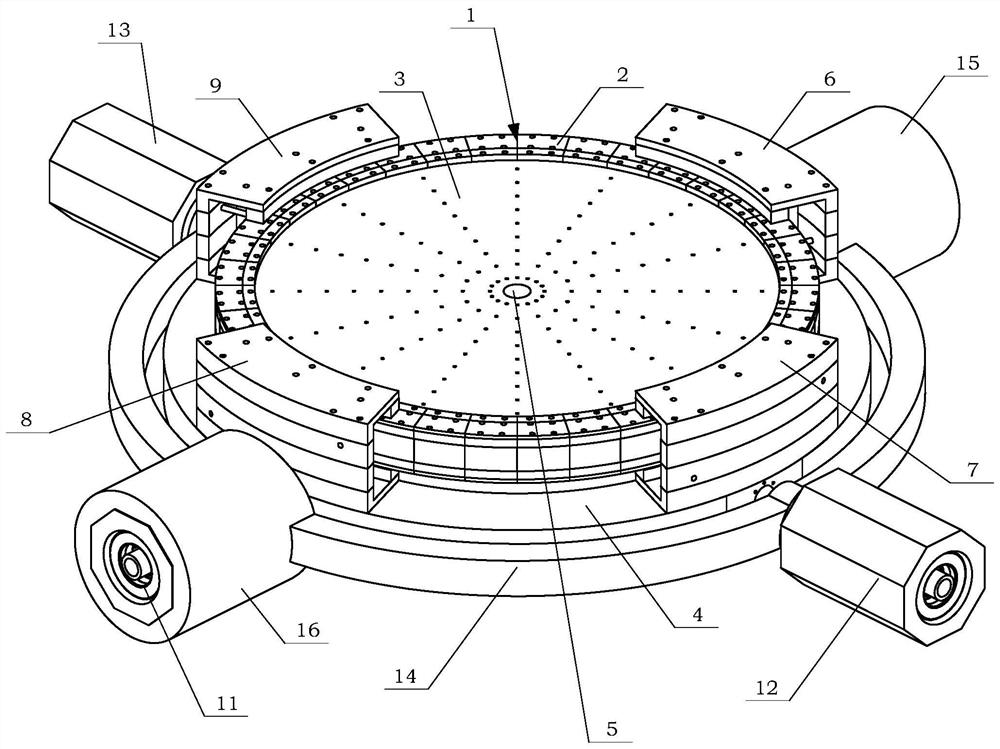

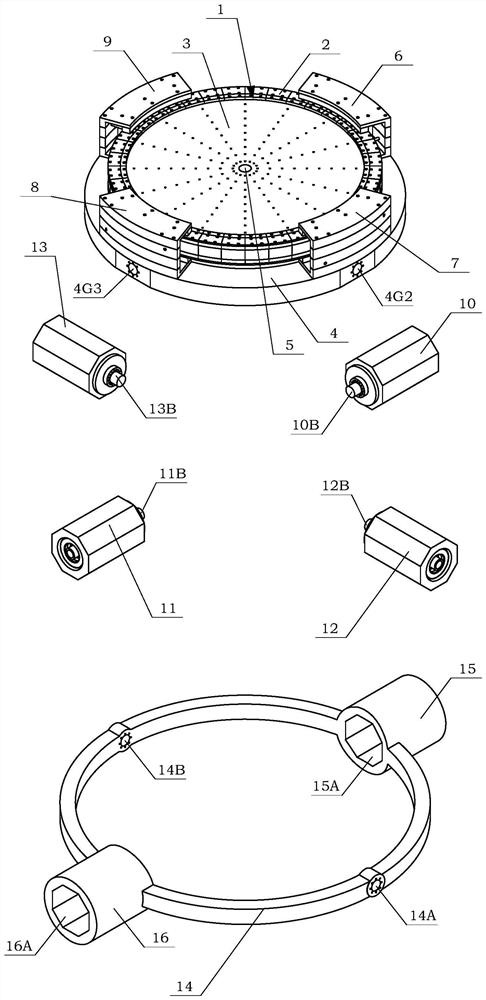

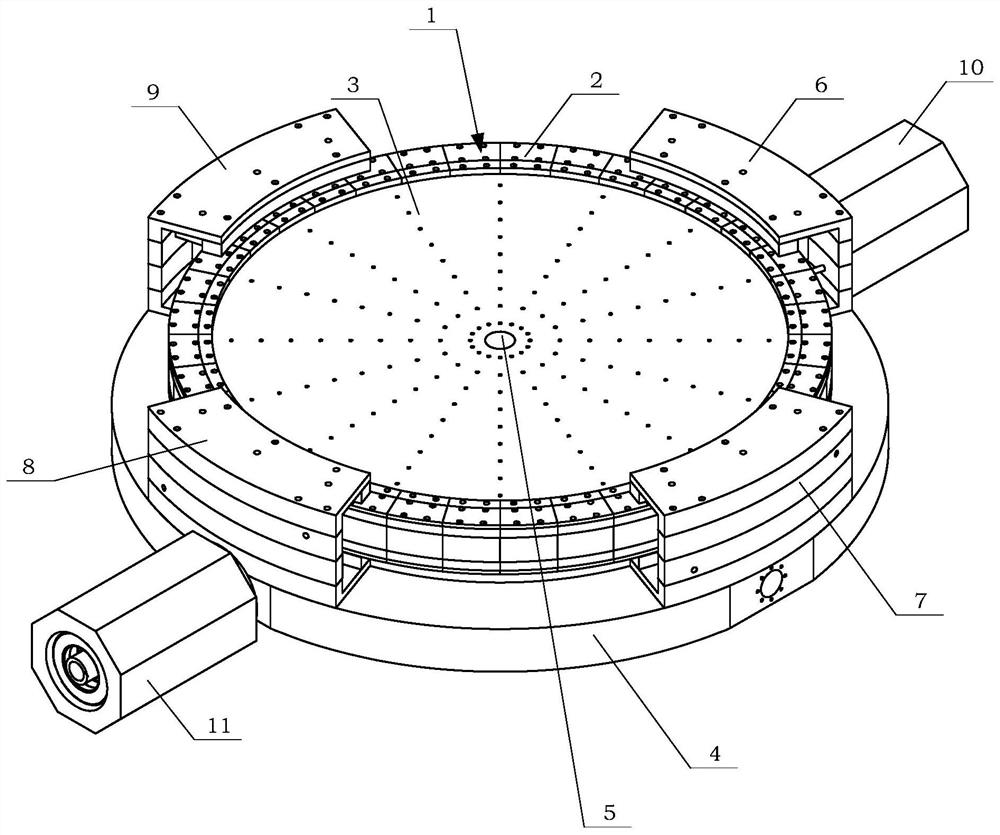

[0059]The invention will be further described in detail below with reference to the accompanying drawings.

[0060]Seefigure 1 ,Figure 1A ,Figure 1B ,Figure 1C As shown, the above-mentioned super-femal / quiet turntable having a fifteen degree of freedom is designed, including a first drive mechanism 10, a second drive mechanism 11, a third drive mechanism 12, a fourth drive mechanism 13, A-axial axial magnetic bearing body stator assembly 6, B-axial axial magnetic bearings, one body stator assembly 7, C-axial magnetic bearings, one body stator assembly 8, D-axial axial magnetic bearings, one-body stator assembly 9, radial axial magnetic bearing The rotor assembly 2, the disc body 3, the base 4, and the uniaxial turntable drive mechanism 5; the circular disk body 3 is distributed in the circular disc body 3, and the rotor assembly 2 constitutes a magnetic suspension rotation platform 1.

[0061]The first drive mechanism 10, the second drive mechanism 11, the third drive mechanism 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com