Auxiliary measuring device and method for percentage elongation after fracture and percentage reduction of area in tensile test

A technology of elongation after fracture and reduction of section, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as inability to guarantee measurement accuracy, waste of detection time, etc., and achieve measurement implementation. The effect of less difficulty, improved measurement accuracy, and simple measurement device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

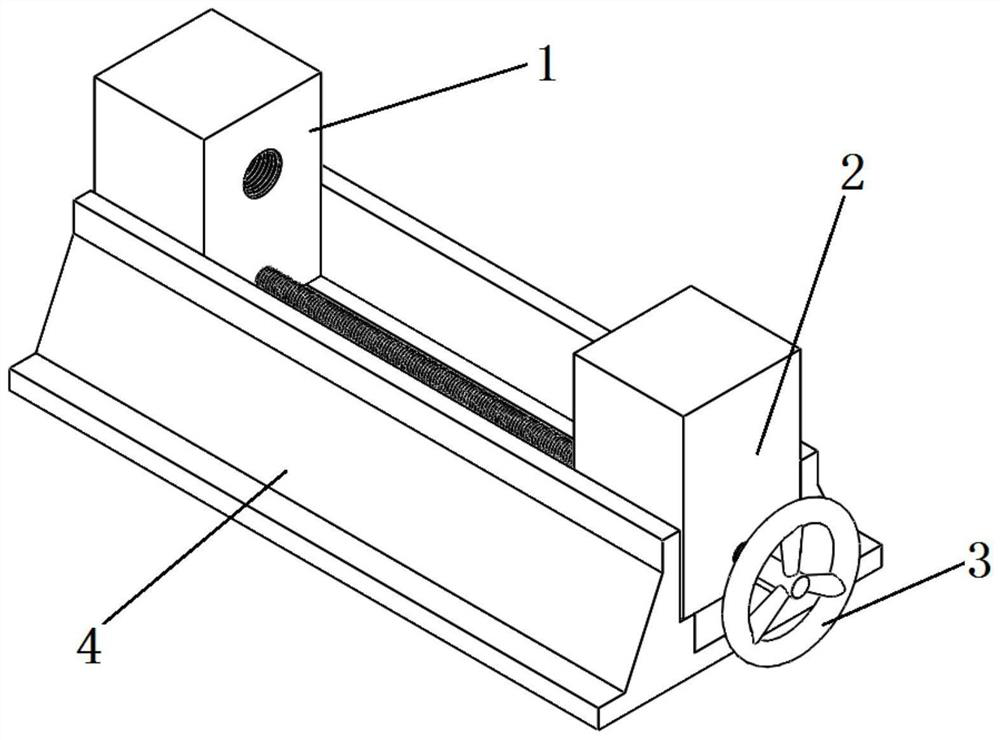

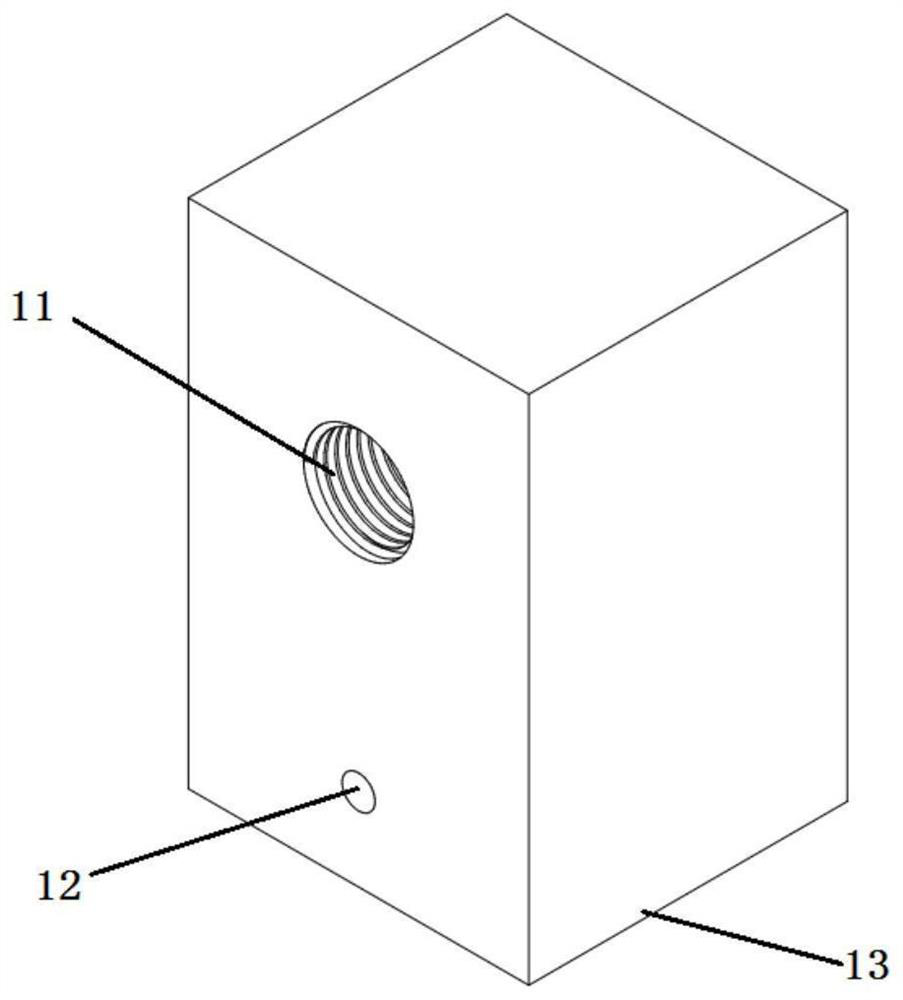

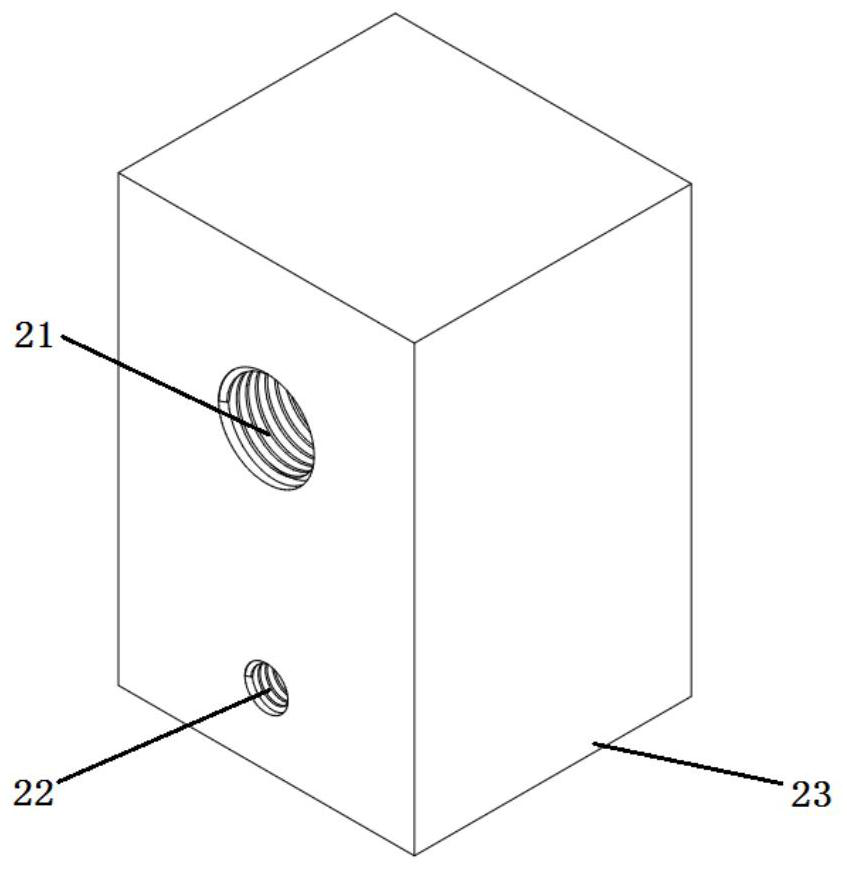

[0072] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0073] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0074] In the present invention, the tensile test refers to a test for measuring a series of properties of a material under the action of a tensile load, also known as a tensile test.

[0075] According to the provisions of GB / T228.1-2010, the elongation after break (A) refers to the residual elongation of the gauge length after break (L u -L 0 ) and the original gauge length (L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com