Copper wire paper stripper and operation method

A technology for stripping paper and flat copper wire, applied in the field of transformers, can solve the problems of inability to protect the paper-wrapped flat copper wire, only stripping, uneven cut surface, etc., to achieve smooth cutting, not easy to be torn, and the cut surface is neat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

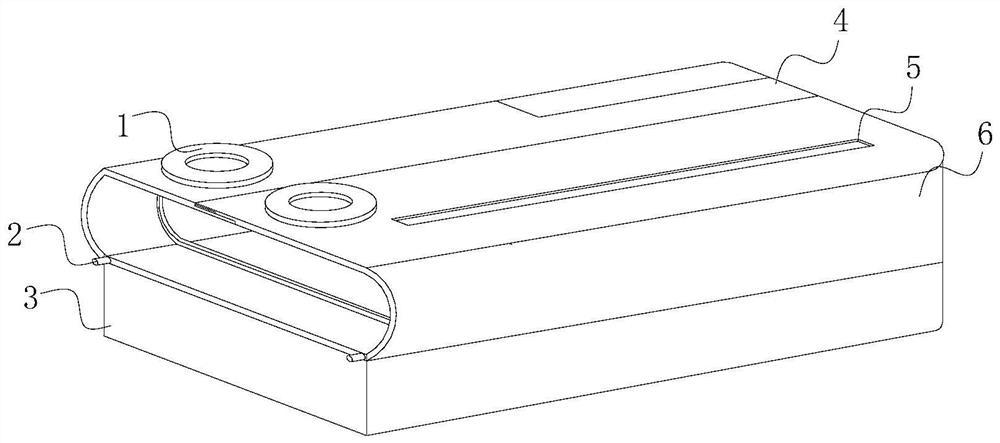

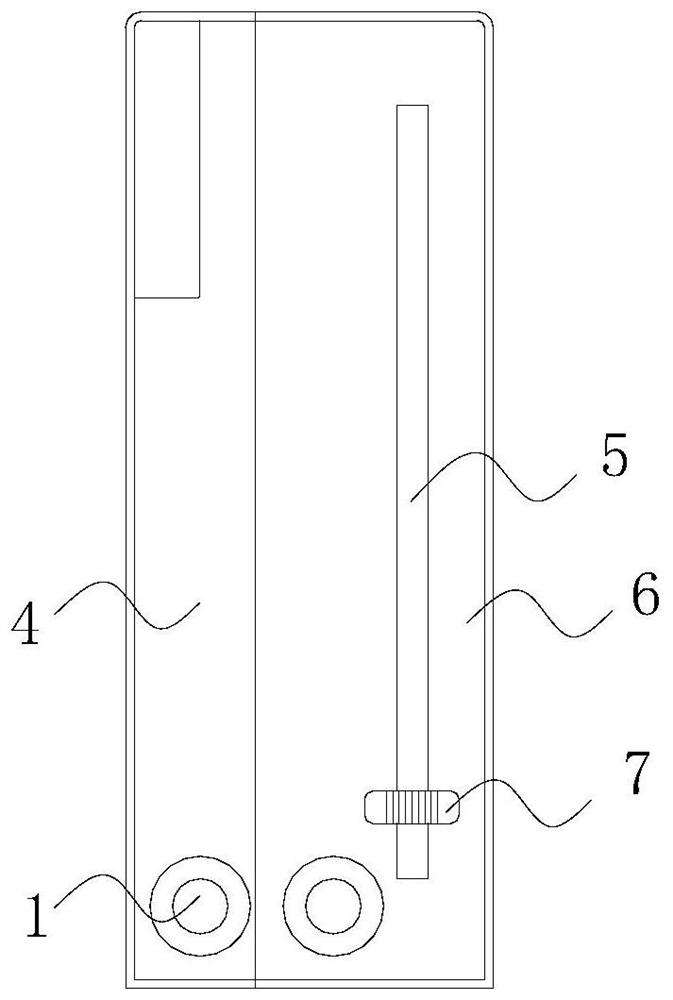

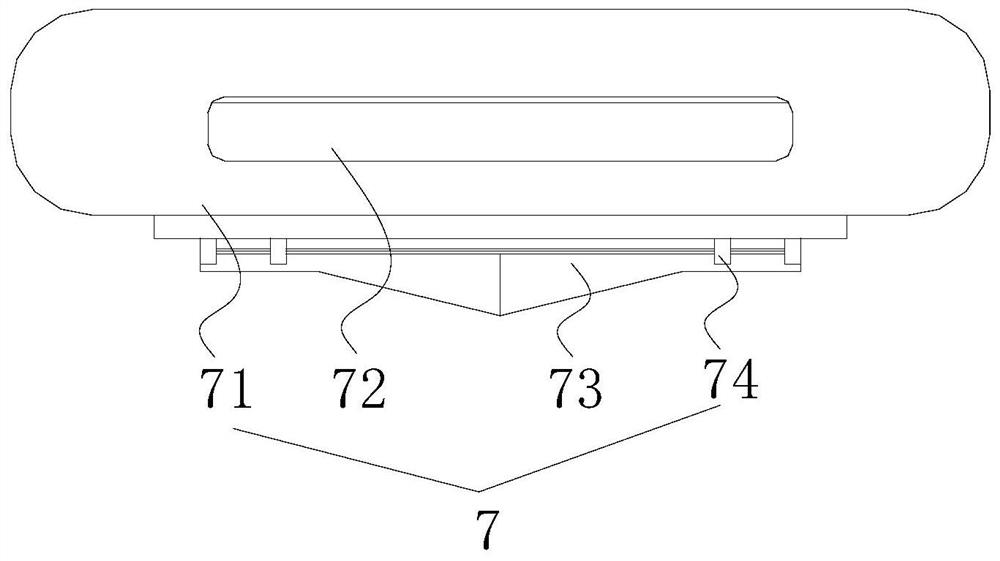

[0027] see Figure 1-Figure 7 , the present invention provides a copper wire stripper and its operation method, its structure includes a pressure plate 1, a connecting shaft 2, a chassis 3, a first opening and closing plate 4, a scoring groove 5, a second opening and closing plate 6, a scoring knife 7, The horizontal left and right sides of the chassis 3 are respectively equipped with a first opening and closing plate 4 and a second opening and closing plate 6 through the connecting shaft 2, and the other ends of the second opening and closing plate 6 and the first opening and closing plate 4 are buckled together. Have a scribe groove 5 on the second opening and closing plate 6, and the length of described scribing groove 5 is less than the length of the second opening and closing plate 6, and does not pass through any one side of the second opening and closing plate 6, is to prevent scratching in the scribe groove 5 The knife 7 breaks away from the scribe groove 5 and cuts pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com