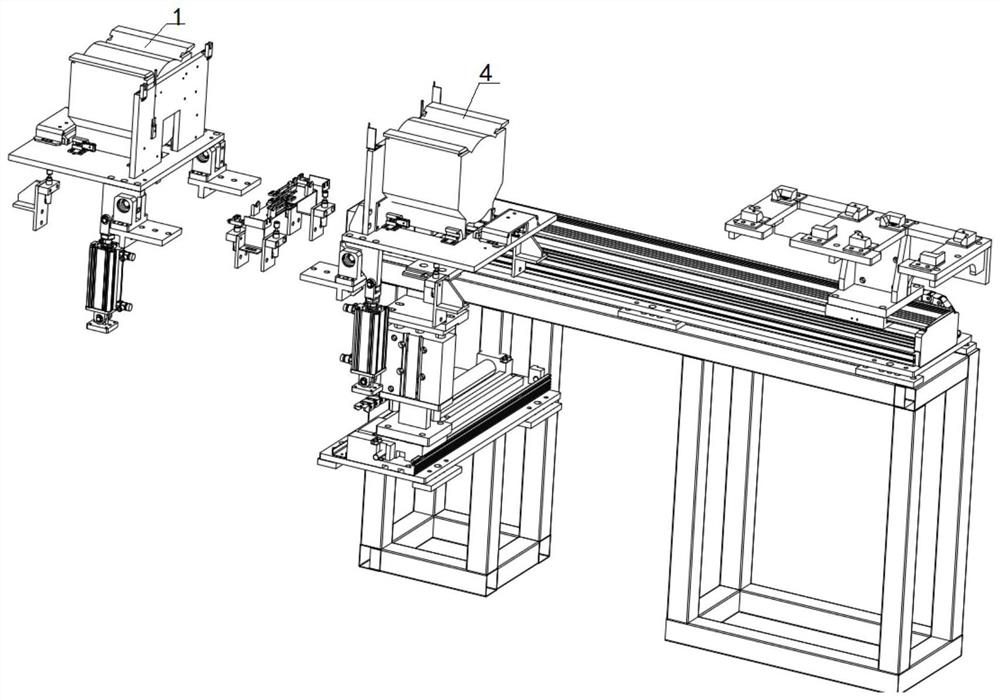

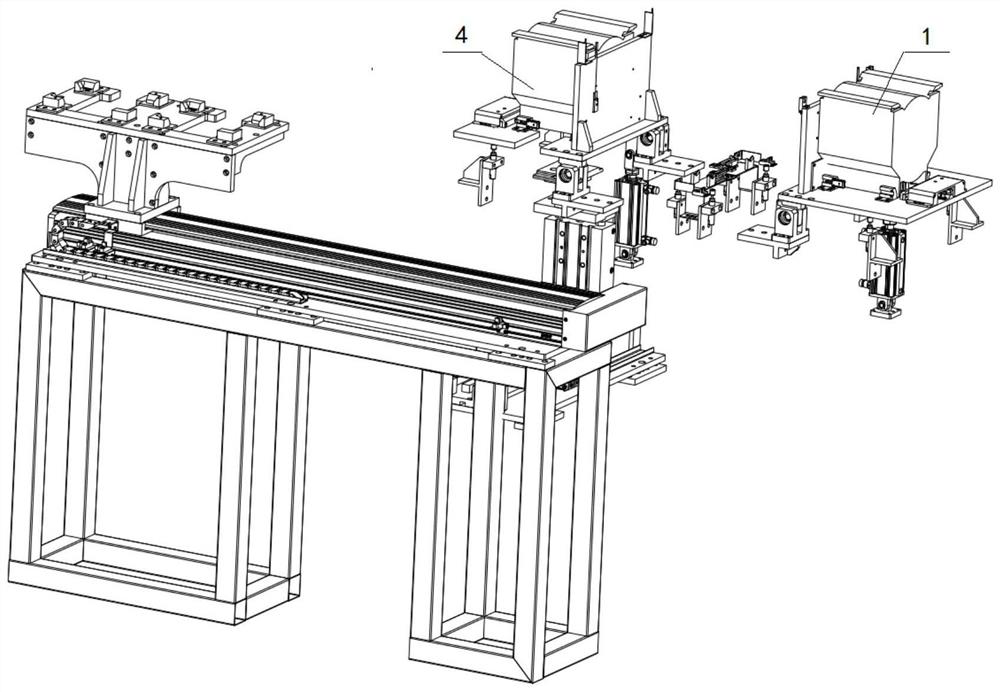

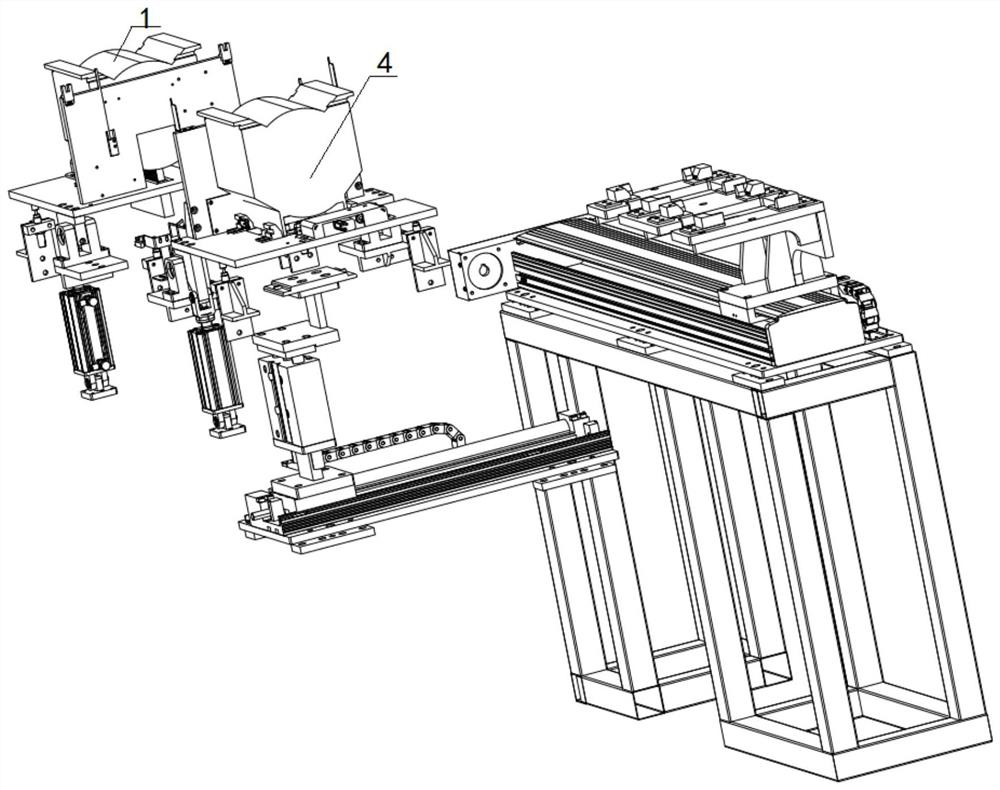

High-efficiency wafer box conveying device of wet cleaning equipment

A technology of wet cleaning and conveying device, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems affecting wafer transfer efficiency, wafer fragmentation, cumbersome operation process, etc., to ensure integrity and stability, increase the utilization rate, and the effect of simple transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0071]The structure of the present embodiment is substantially identical to the structure of the first embodiment, and the wafer detector is increased, and the wafer detector includes detecting the cylinder 12 and the detection sensor 13, detecting the sensor 13, and the detection sensor 13. The detection cylinder 12 is disposed directly below the first horizontal placement plate 2 structure. The first wafer cartridge 1 is provided with a plurality of wafer card slots, and the adjacent wafer card grooves form a card slot gap, and the detecting sensor 13 includes a plurality of parallel setting detecting sensing sheets. A card slot gap is formed between the adjacent wafer card grooves, and the detecting sensor 13 includes a plurality of parallel setting detecting sensors 13, detecting the position of the sensing sheet to the position of the card slot gap. In the receiving mechanism, the sliding push is increased, the sliding push hand includes the sliding track 9 and the push arm 10,...

Embodiment 3

[0073]This embodiment provides a wafer loading delivery method, and its working process is as follows:

[0074]Step 1, the first horizontal place plate 2, the second horizontal place plate 5 is in a horizontal state in contact with the carrier 11, and the first vertical place plate 3, the second vertical place plate 6 is in a vertical state. The first wafer cassette 1 is loaded with a wafer, and the second wafer cassette 4 is an air load, and the sliding push is away from the first wafer box 1. The first limiting cylinder 21, the second resident cylinder 23 operates, and the first wafer cassette 1 is fixed to the first horizontal place plate 2, and the second wafer cartridge 4 is fixed to the second horizontal placing plate 5.

[0075]Step 2, the drive mechanism at the first placement is simultaneously operated with the drive mechanism at the second placement, and the first placement, the second placement is simultaneously rotated 90 degrees, the first wafer box 1, the second wafer The op...

Embodiment 4

[0082]This embodiment provides a wafer unloading delivery method, and its working process is as follows:

[0083]Step 6. The mechanical clamping mechanism takes the wafer box to the transfers orbit 24.

[0084]Step 1, after the two wafer casings are induced to the wafer box signal, the controller controls the third drive mechanism to move the transfer carrier plate 25 to the second horizontal placement plate 5 ends close to the second horizontal placement plate 5.

[0085]Step 2, the adapter slider 28 is at the push-off point position of the first wafer cassette of the middle transfer carrier 25, and the pushing cylinder 29 is moved to move the push plate 32 to the hollow structure 30 on the middle transfer carrier 25, push plate 32 and crystal The bottom of the circle box is in contact, and the push cylinder 29 continues to operate, and the wafer box is pushed away from the middle transfer plate 25, and when the third sense switch is in the wafer box, the signal is transmitted to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com