Expandable double-layer hybrid space planar antenna

A planar antenna, hybrid technology, applied in the field of spacecraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

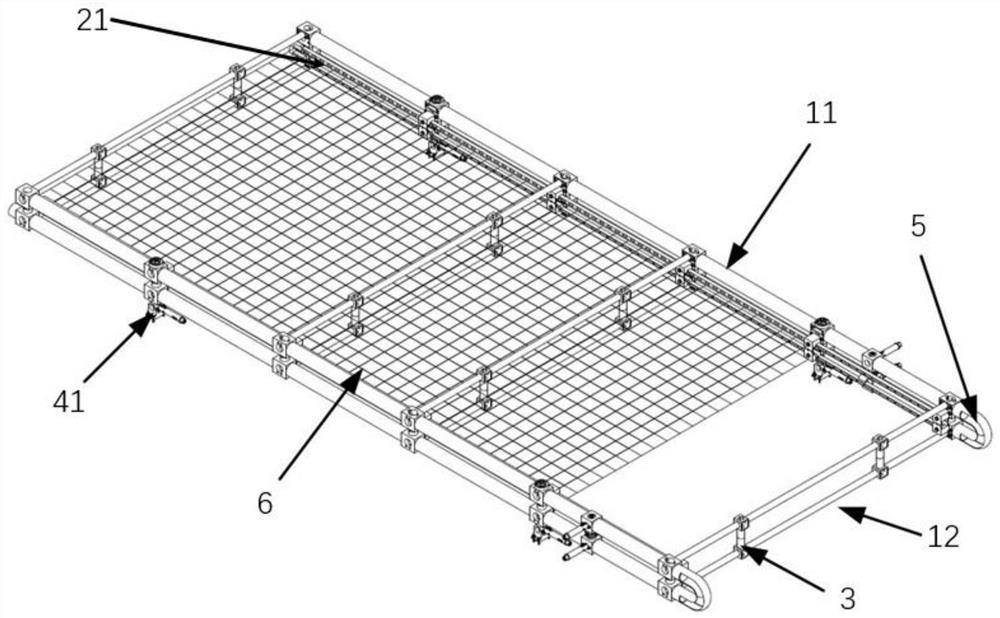

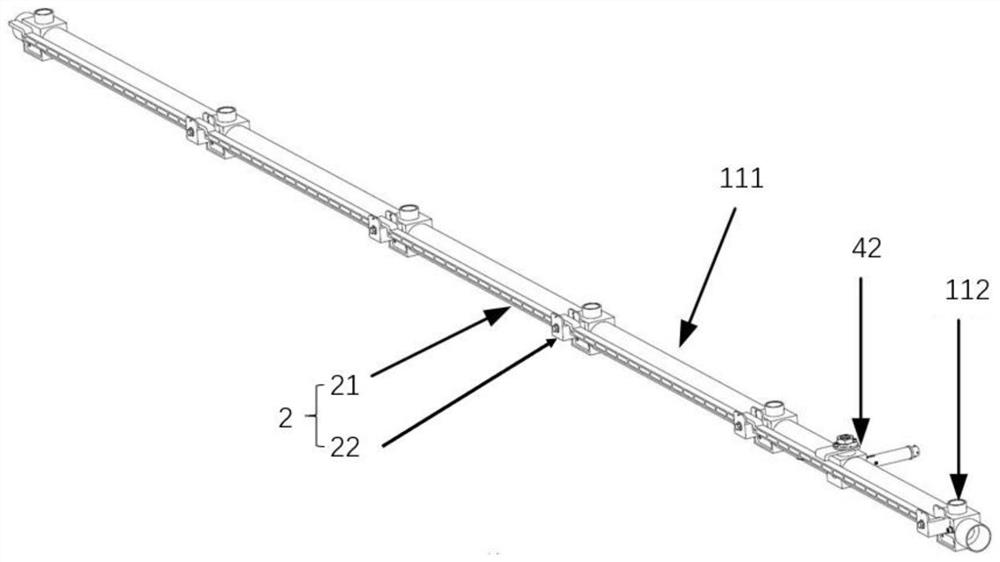

[0032] The present invention provides an expandable double-layer hybrid space planar antenna, which includes a planar film antenna frame 1 , a three-dimensional metal mesh antenna frame assembly 2 , a compression seat 3 , a compression release device 4 and a flexible hinge 5 . The planar film antenna frame 1 is a frame with a rectangular structure, including a spreading rod 11 and a cross bar 12. The two spreading rods 11 are parallel to each other. The two spreading rods 11 are connected and fixed by a plurality of cross bars 12. The number of the cross bars 12 is Two or more cross bars 12 located between two deployment bars 11 are parallel to each other. Preferably, the deployment rod 11 is formed by fastening and connecting a plurality of carbon fiber thin-walled rods 111 through compression joints 112. Further, the carbon fiber thin-walled rods 111 are formed by glueing thin-walled carbon fiber tubes. The thin-walled carbon fiber tube forms the carbon fiber thin-walled rod...

Embodiment 2

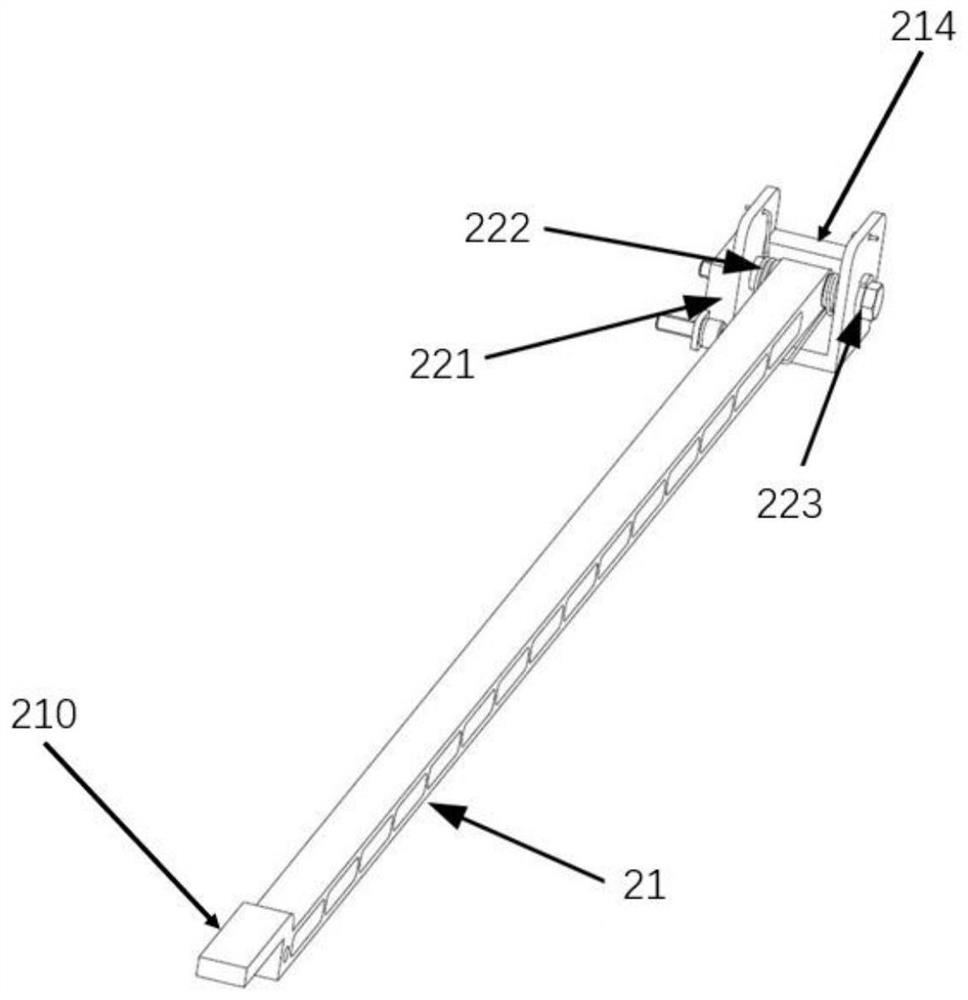

[0041] This embodiment 2 is formed on the basis of embodiment 1. Through the structural optimization design of the three-dimensional metal mesh antenna frame assembly, the metal mesh support rods on one side can be sequentially pressed on the inside of the frame, and a compression release device can be used. Realizing the folding and folding of multiple groups of metal mesh support rods on one side, the system structure is simplified, and the reduction in the number of pressing and releasing devices further reduces the overall weight of the system, which improves the reliability of the metal mesh support rods on-rail unlocking and releasing.

[0042] The metal mesh support rod 21 is designed as a structure with a Z-shaped end 210 , and the Z-shaped end 210 is located at the other end opposite to the end connected to the base 221 . Multiple sets of metal mesh support rods 21 connected to the same expansion rod 11 are connected end to end, and the way of connection is that the Z-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Folding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com