Electrical connector and manufacturing method thereof

An electrical connector and electrical connection technology, which is applied in the connection, the manufacture of the contact box/base, the parts of the connecting device, etc., can solve the problem that the connecting part is easily scratched by external objects, and the connecting part is easily scratched. staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate a better understanding of the purpose, structure, features and effects of the present invention, the present invention will now be further described with reference to the accompanying drawings and specific embodiments.

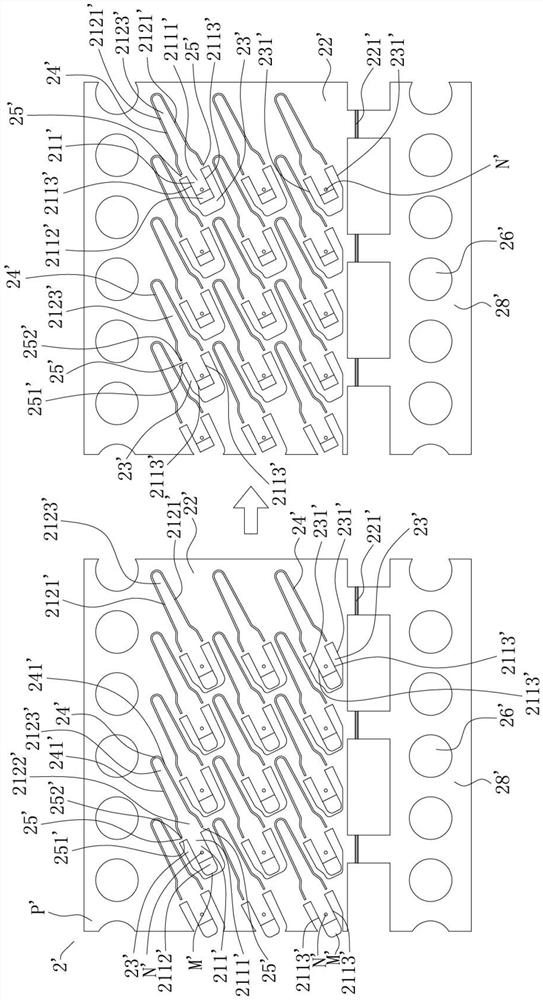

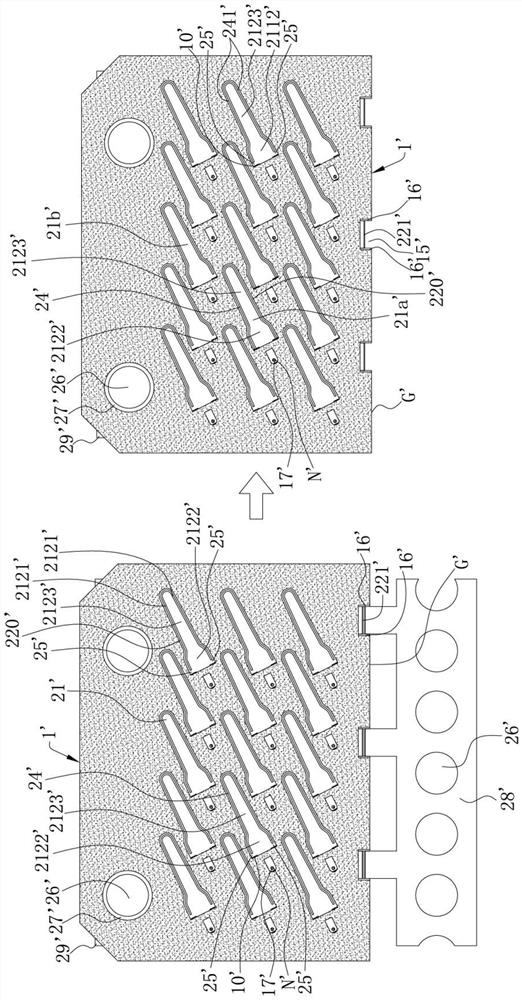

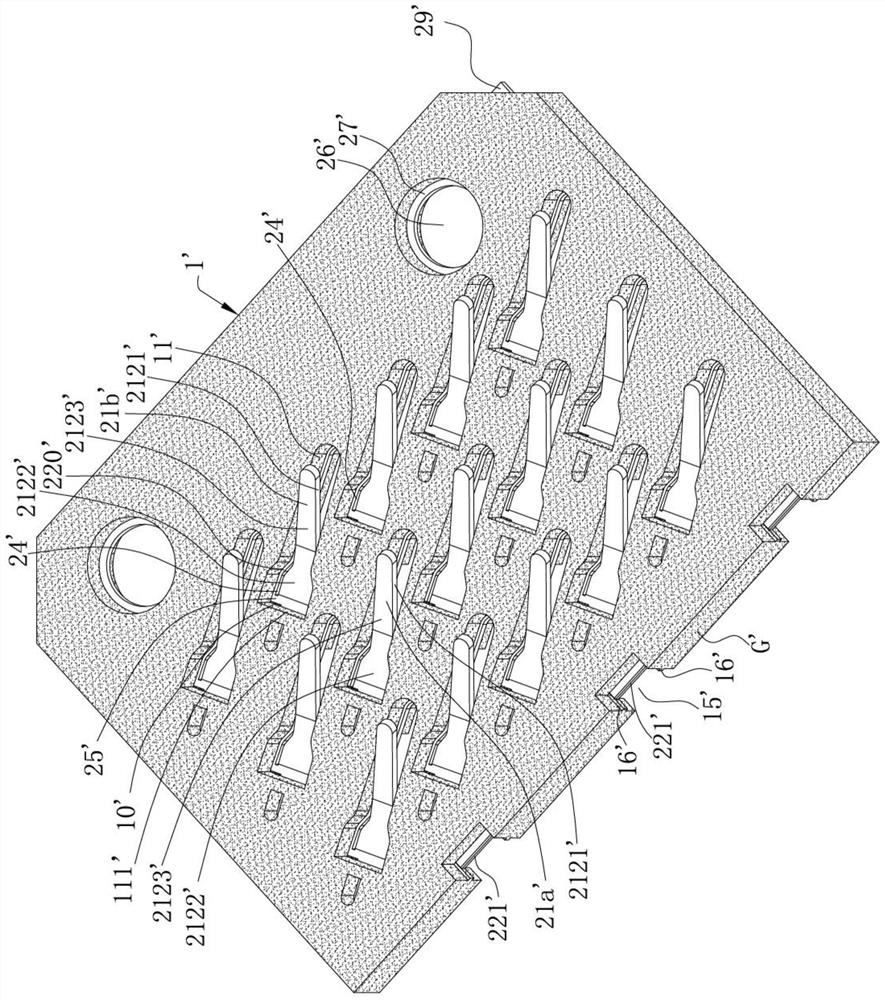

[0032] see image 3 , Figure 4 , Figure 7The electrical connector is used to electrically connect a first docking element E' and a second docking element F', and includes: an insulating body 1', a plurality of conductive parts that are insert-molded with the insulating body 1', and a The base plate 22', the conductive member and the base plate 22' are jointly cut from a metal sheet P'. The base plate 22' is arranged horizontally and is accommodated in the insulating body 1'. In this embodiment, The first docking element E' is a chip module, the second docking element F' is a circuit board, and the conductive member is a terminal 21' (of course, in other embodiments, the conductive member can also be a terminal 21 ' ', which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com