Motor cover and dust-sewage separation device

A technology of motor cover and motor base, which is applied to the installation of electromechanical devices, exhaust diffusion devices, and electrical equipment, and can solve problems such as loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

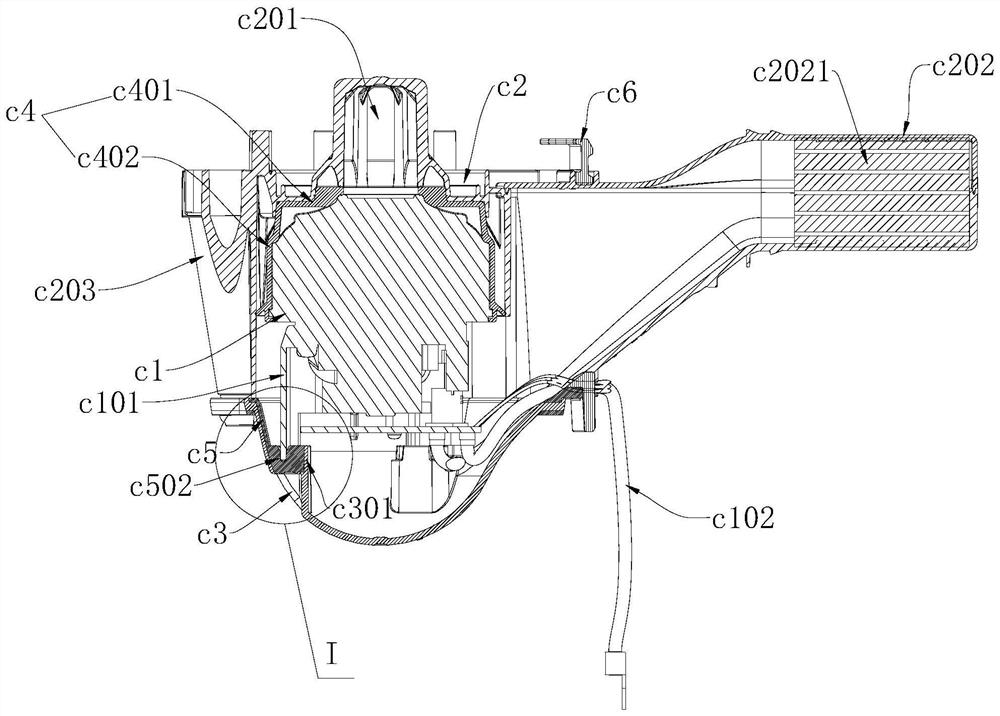

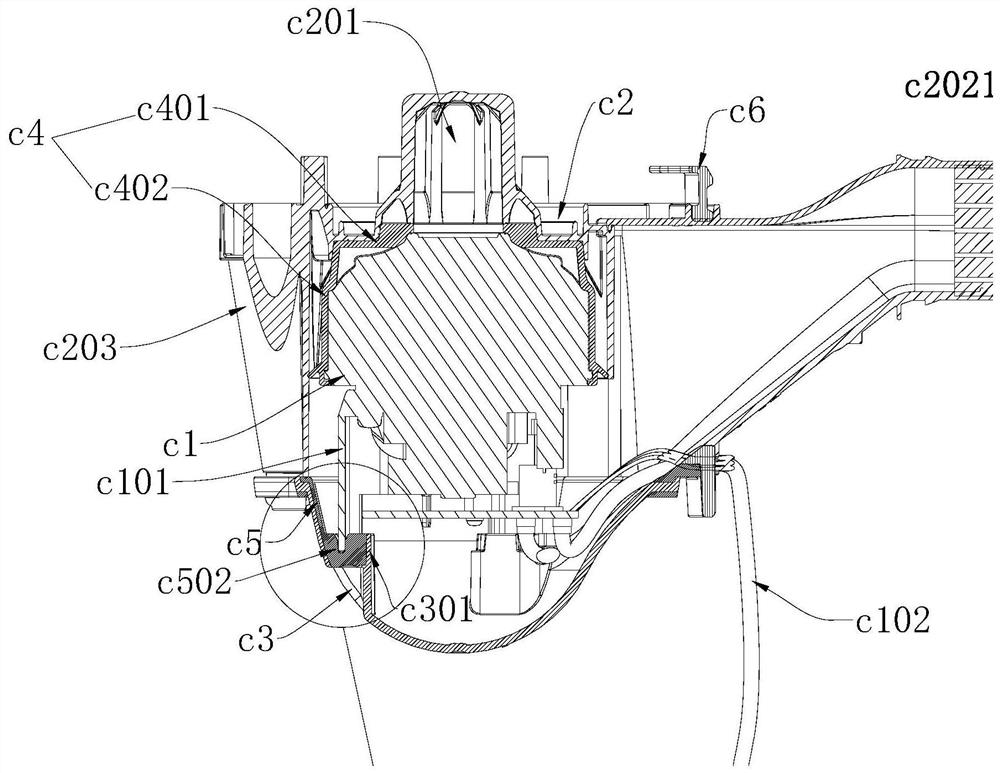

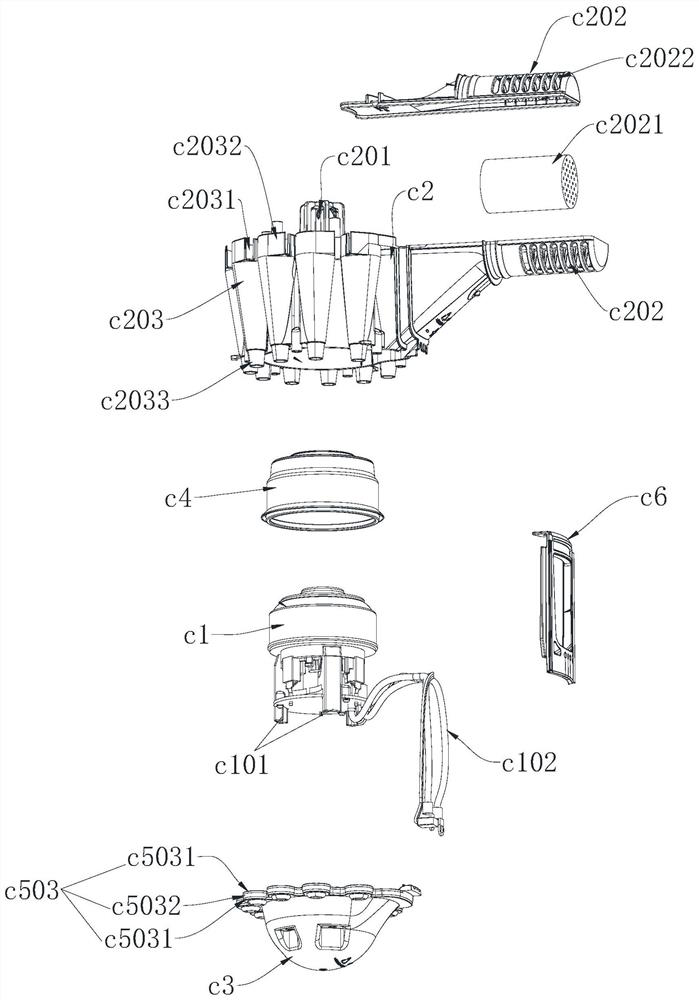

[0071] The invention provides a motor cover, such as figure 1 , figure 2 As shown, it includes: motor base c3, on which the vacuum motor c1 is supported and installed; The housing chamber for the vacuum motor c1 is opened to one side of the motor base c3; the motor seal c4 is arranged in the motor housing c2, and the motor seal c4 is clamped on the motor base c3 Between the motor housing c2 and the vacuum motor c1; the base shock absorber c5 is supported between the motor base c3 and the vacuum motor c1. The vacuum motor c1 is installed in the motor cover, and the upper and lower sides of the vacuum motor c1 are fastened and fixed through the motor shell c2 and the motor base c3 respectively, and a motor seal is interposed between the vacuum motor c1 and the motor shell c2 part c4, the motor seal c4 can make up the gap between the vacuum motor c1 and the motor casing c2, reduce the structural gap between the motor cover and the vacuum motor c1, and can be combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com