Rubber composition comprising a polyphenolic compound

A technology of rubber composition and polyphenol compound, applied in transportation and packaging, special tires, tire parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

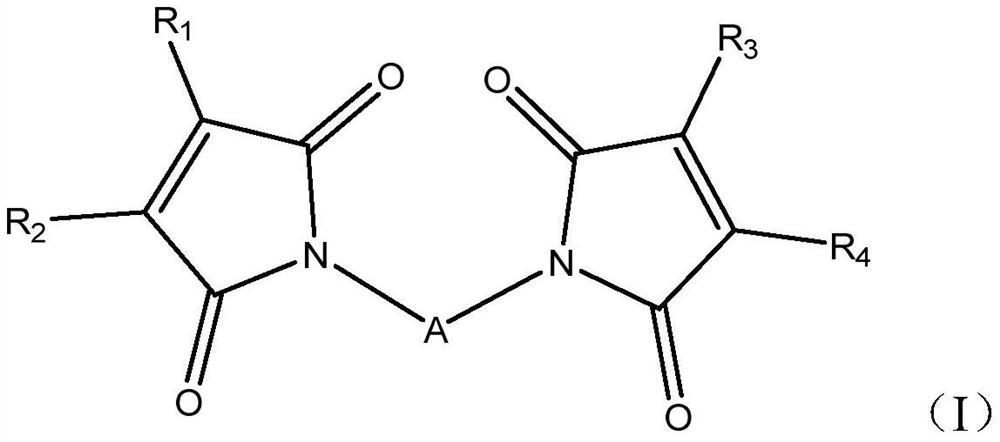

Method used

Image

Examples

Embodiment Construction

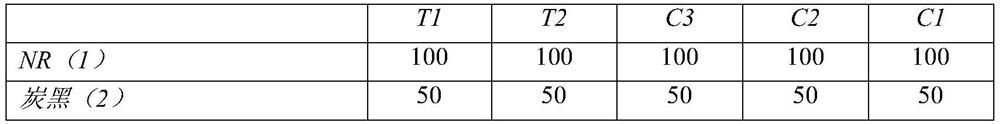

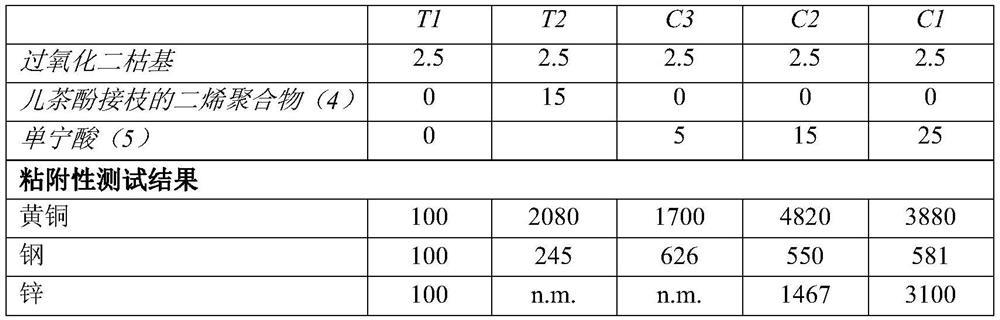

[0216] The following procedure was used to prepare the different rubber compositions: The elastomer and all other components of the mixture were successively introduced into an internal mixer (final degree of filling: about 70% by volume), the initial temperature of the vessel being about 60°C. Thermomechanical processing is then carried out in one stage until a maximum "outgoing" temperature of 150°C is reached. The mixture thus obtained is recovered, then cooled at 30° C. on an open mixer (homogenous finisher), and everything is mixed.

[0217] The crosslinking system is added according to the knowledge of the person skilled in the art, the polyacid crosslinking system is added during the first stage and the peroxide and sulfur based crosslinking system is added during the second stage.

[0218] The rubber compositions produced are presented in Tables 1, 2 and 3.

[0219] The quality of the adhesion between the rubber composition and the reinforcing element is determined by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com