Insulation coating composition for electrical steel sheet and electrical steel sheet with insulation coating

An electrical steel sheet and insulating coating technology, applied in inorganic insulators, metal oxides, metal material coating processes, etc., can solve the problems of dust generation, surface whitening defects, deterioration of heat resistance, etc., and achieve good efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1-1

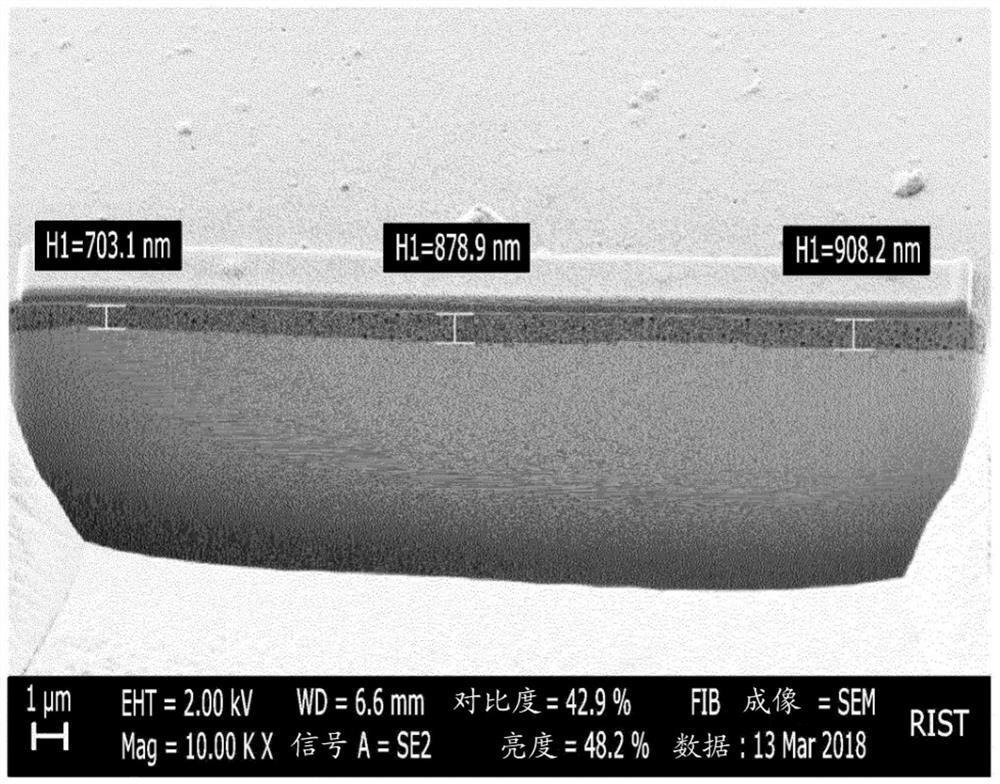

[0220] Experimental Example 1-1: According to the characteristics of the type of silane compound

Embodiment 1-1

[0222] Prepare a slab containing silicon (Si): 3.4% by weight, aluminum (Al): 0.80% by weight, manganese (Mn): 0.17% by weight, titanium (Ti): 0.0015% by weight, tin (Sn): 0.03 % by weight, nickel (Ni): 0.01% by weight, carbon (C): 0.003% by weight, nitrogen (N): 0.0013% by weight, phosphorus (P): 0.012% by weight, sulfur (S): 0.001% by weight, balance Composed of Fe and other unavoidable impurities.

[0223] The slab was heated at 1130° C. and then cold-rolled to a thickness of 2.3 mm to produce a hot-rolled sheet.

[0224] Coil the hot-rolled sheet at 650°C, then cool it in the air, anneal the hot-rolled sheet at 1040°C for 2 minutes, then quickly cool it in water and pickle it, and then cold-roll it to a thickness of 0.35mm. Manufacture of cold rolled sheet.

[0225] The cold-rolled sheet was subjected to final annealing at 1040°C for 50 seconds in a 20% hydrogen, 80% nitrogen atmosphere with the dew point adjusted to produce an annealed steel sheet.

[0226] As an insul...

Embodiment 1-2 to 1-12

[0228] The implementation method was the same as that of Example 1-1, but the contents and types of the silane compound, metal hydroxide and metal nitride in the insulating coating composition were replaced as shown in Table 1 below to form an insulating coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com