Commutator motor

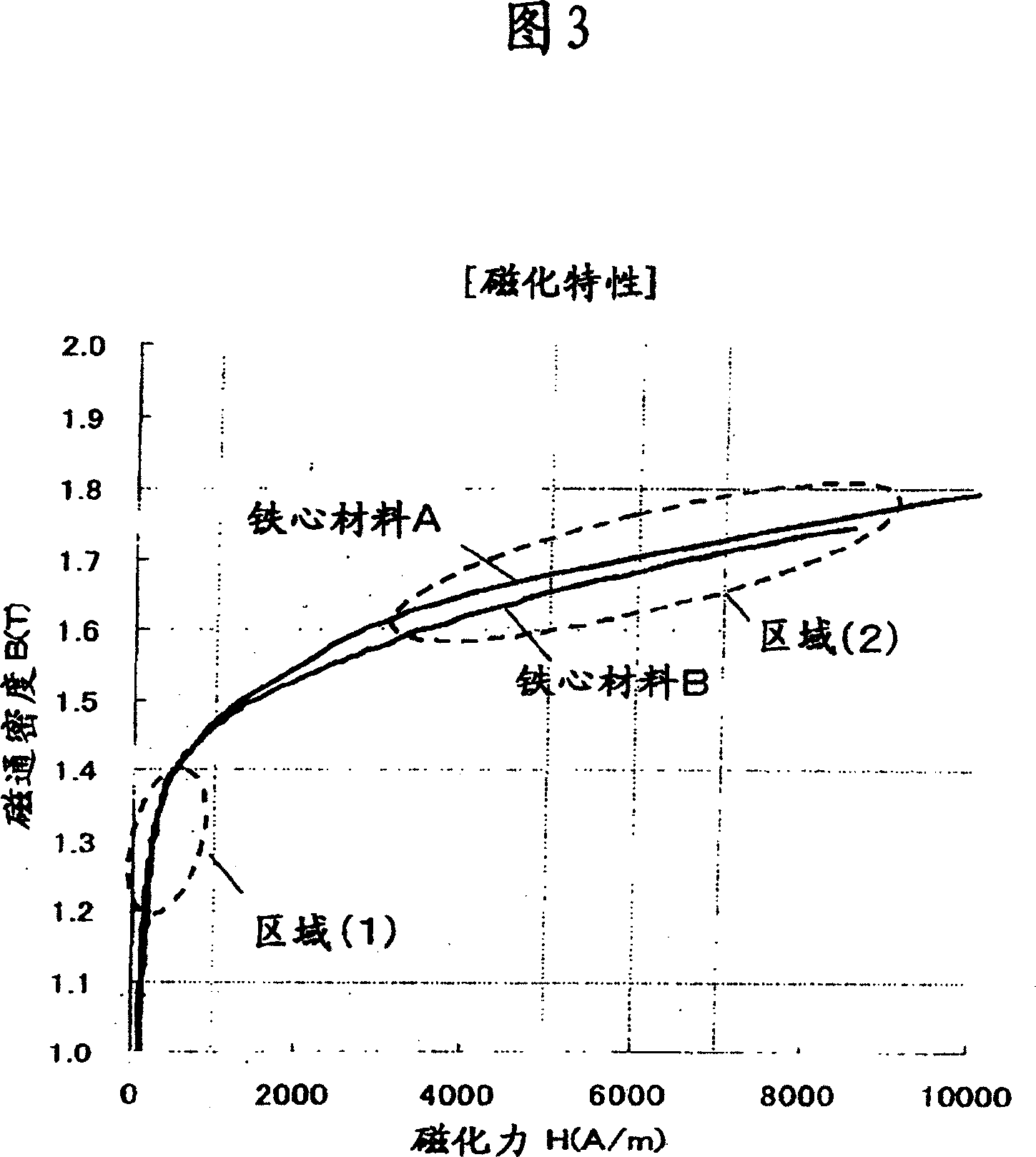

A technology of electric motor and commutator, which is applied in the field of iron core composition of commutator motors, can solve the problems such as difficulty in reducing copper loss, improving efficiency, reducing cross-sectional area, etc., and achieves the effect of reducing iron loss and suppressing the increase of excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

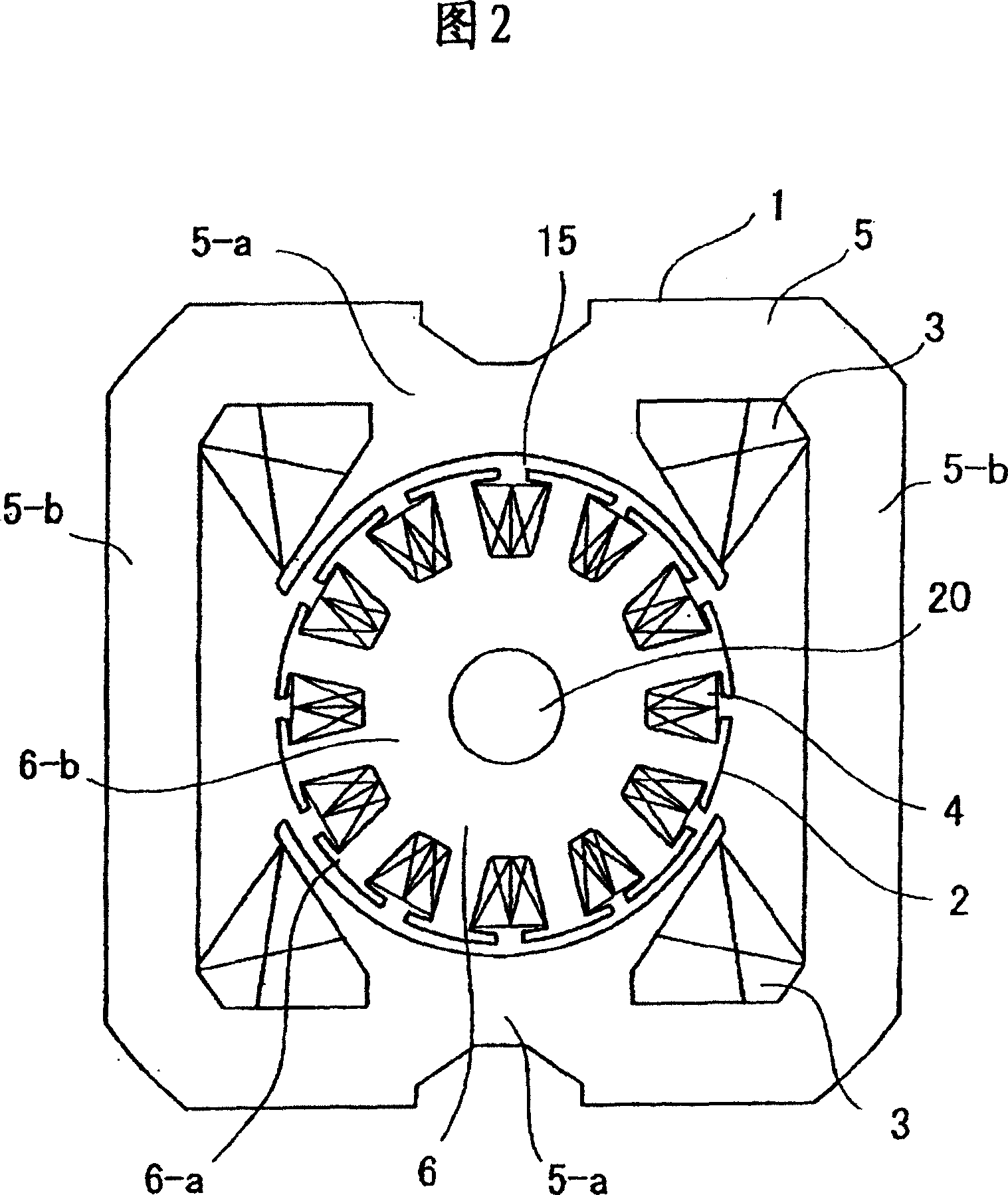

[0023] An example of an embodiment of the present invention will be described below with reference to FIGS. 1 to 6 .

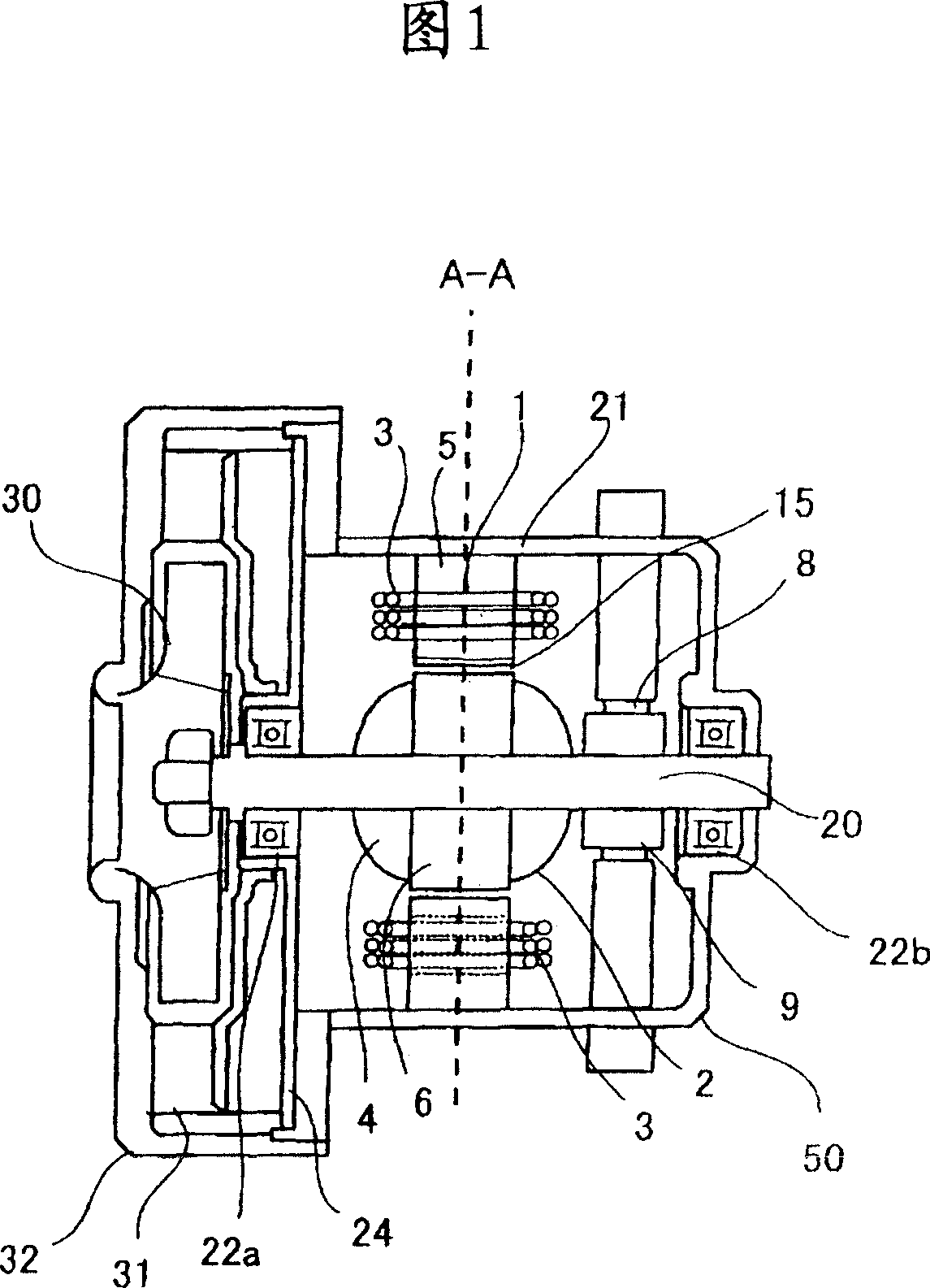

[0024] Fig. 1 shows an embodiment of the constitution of the electric blower according to the present invention. The motor side of the electric blower 50 is composed of an armature 2 and a stator 1 within a housing 21 and an end bracket 24 . In addition, a diffuser 31 and a casing 32 are provided to surround a fan 30 provided at an output shaft end of the motor.

[0025] The stator 1 of the electric motor is composed of a stator core 5 and an exciting coil 3 inside a housing 21 , and by passing a current through the exciting coil 3 , main magnetic flux is generated from the exciting magnetomotive force. The armature 2 disposed with a gap 15 from the stator core 5 has a shaft 20 supported by bearings 22a and 22b provided at the shaft centers of the casing 21 and the end bracket 24, and the commutator 9 and the armature core are provided on the shaft 20. 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com