Grain-oriented electrical steel sheet and manufacturing method thereof

An electromagnetic steel sheet and orientation technology, applied in the direction of manufacturing tools, circuits, electrical components, etc., can solve the problems of insulation degradation, insulation coating damage, etc., and achieve low energy loss, excellent iron loss characteristics, and excellent space factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

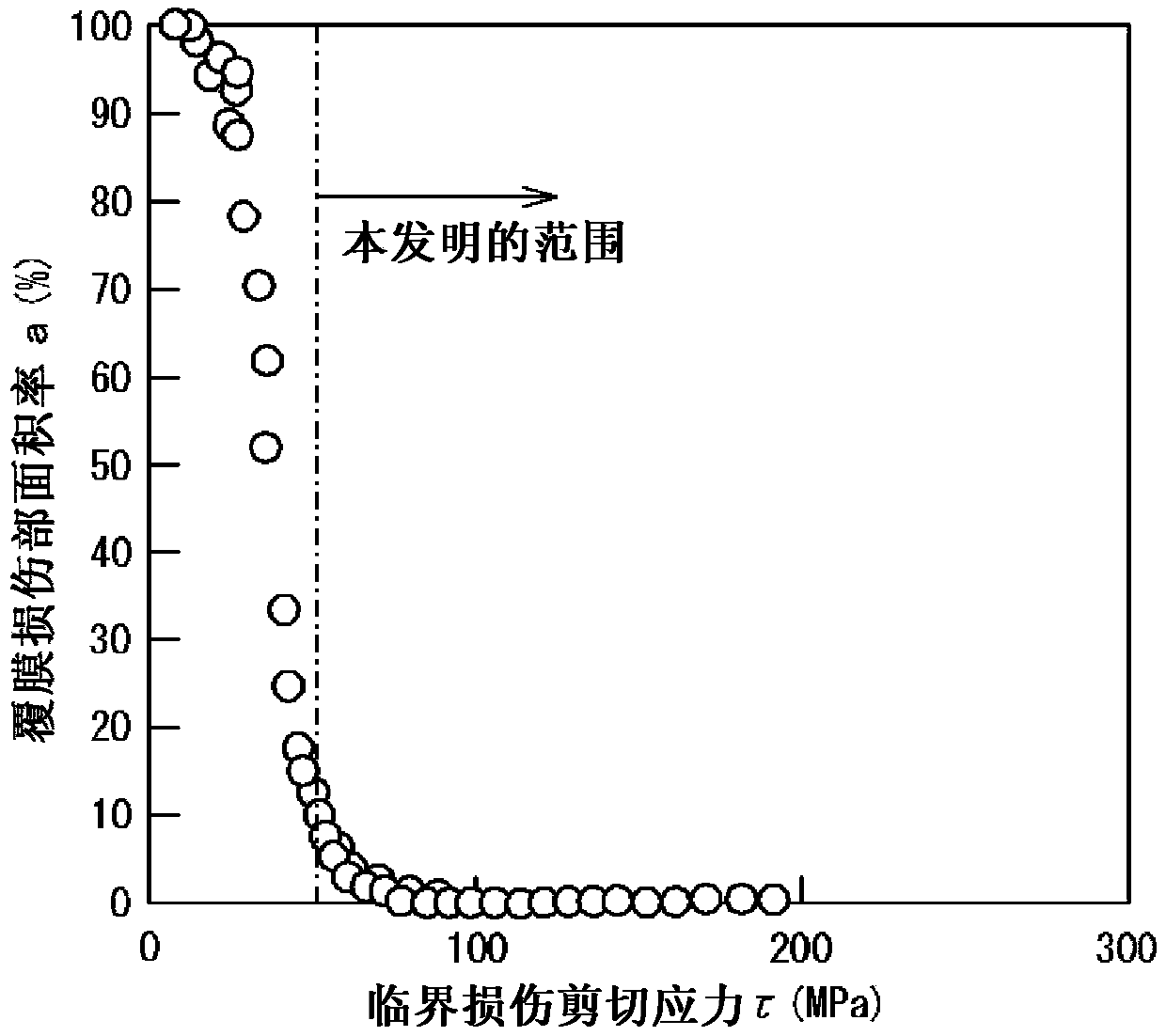

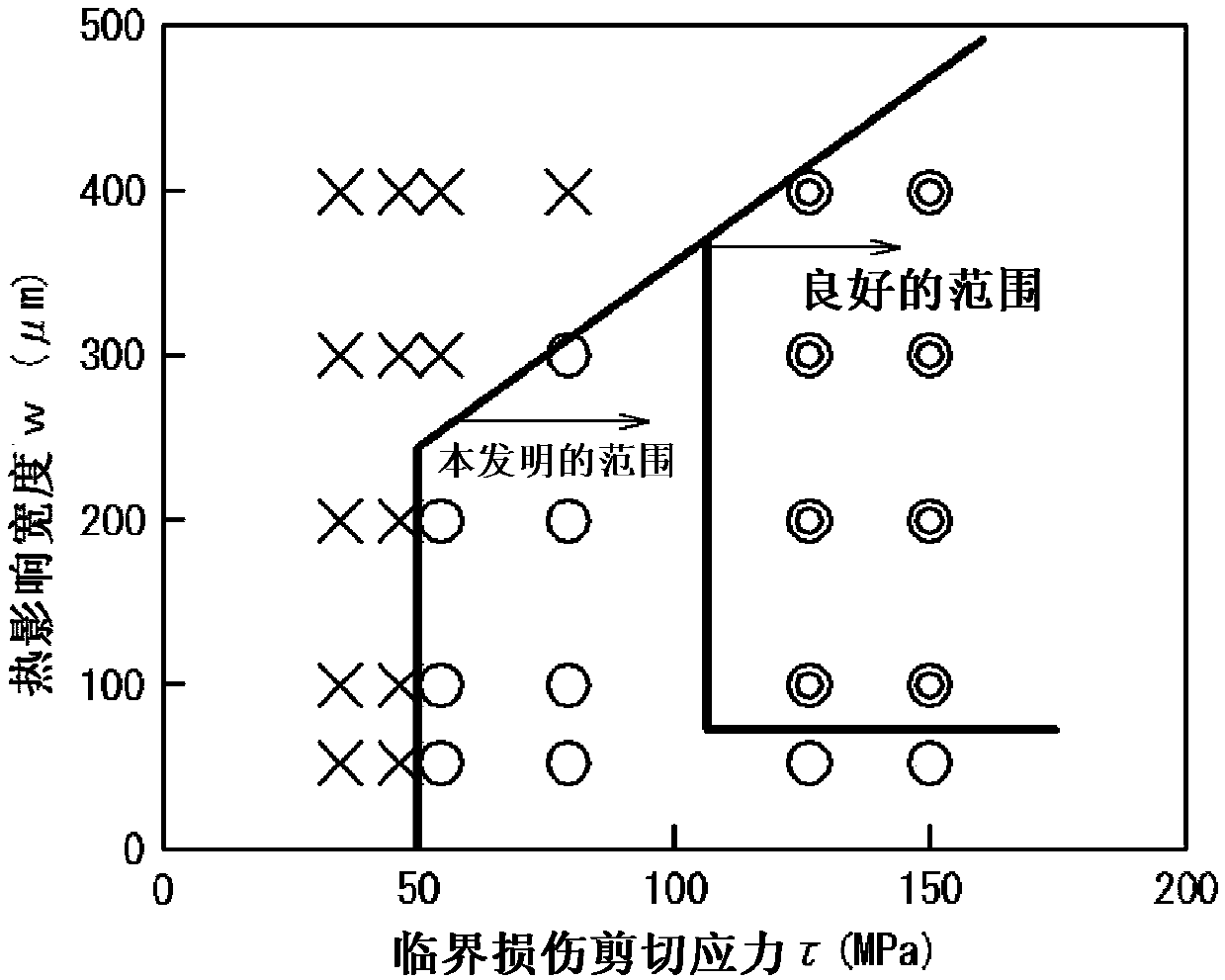

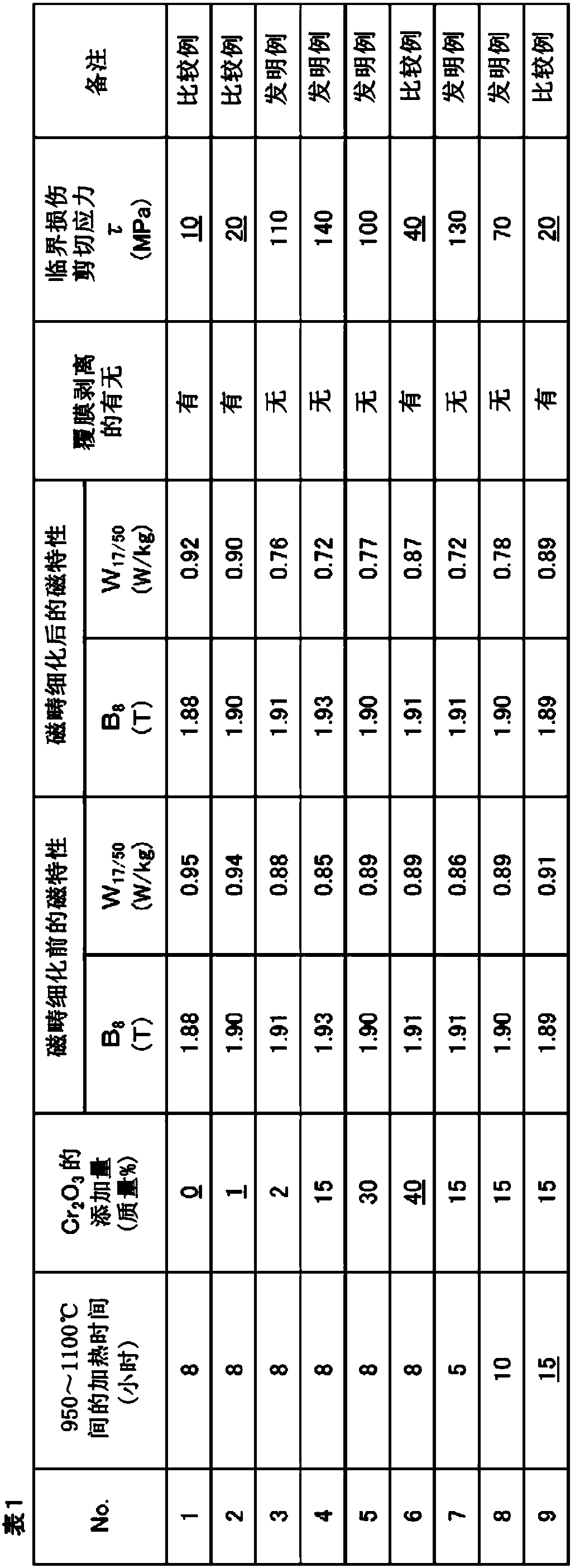

Embodiment 1

[0086] A steel containing C: 0.065%, Si: 3.4%, and Mn: 0.08% was melted and cast into billets by continuous casting. Next, after heating to 1410°C, it is hot-rolled into a hot-rolled sheet with a thickness of 2.4mm. After annealing the hot-rolled sheet at 1050°C for 60 seconds, it is cold-rolled once to make the intermediate sheet thickness 1.8mm. After performing intermediate annealing for 80 seconds, it was made into the cold-rolled sheet whose final sheet|seat thickness was 0.23 mm by 200 degreeC warm rolling. Next, in the oxidatively wet H 2 -N 2 Decarburization annealing which doubles as primary recrystallization annealing was performed at 820° C. for 80 seconds in an atmosphere. Then, the surface of the steel plate is coated with MgO as the main body, and Cr is added in various changes within the range of 0 to 40%. 2 o 3 The annealing separation agent, after drying, implements secondary recrystallization annealing including changing the time spent heating between 950...

Embodiment 2

[0093] A steel containing C: 0.070%, Si: 3.2%, and Mn: 0.1% was melted and cast into billets by continuous casting. Next, after heating to 1410°C, it is hot-rolled into a hot-rolled sheet with a thickness of 2.4mm, and after annealing the hot-rolled sheet at 1050°C for 60 seconds, it is cold-rolled once to make the intermediate sheet thickness 1.9mm, and then rolled at 1120°C. After performing intermediate annealing for 80 seconds, it was made into the cold-rolled sheet whose final sheet|seat thickness was 0.23 mm by 200 degreeC warm rolling. Next, in the oxidatively wet H 2 -N 2 Decarburization annealing, which doubles as primary recrystallization annealing, was performed at 840° C. for 100 seconds in an atmosphere. Then, the surface of the steel plate is coated with MgO as the main body and 10% Cr 2 o 3 After the annealing separation agent was dried, final annealing was performed including secondary recrystallization annealing and purification treatment at 1200° C. for 7...

Embodiment 3

[0098] A steel containing C: 0.070%, Si: 3.2%, and Mn: 0.1% was melted and cast into billets by continuous casting. Next, after heating to 1410°C, it is hot-rolled into a hot-rolled sheet with a thickness of 2.4mm. After annealing the hot-rolled sheet at 1050°C for 60 seconds, it is cold-rolled once to make the intermediate sheet thickness 1.9mm. After performing intermediate annealing for 80 seconds, it was made into the cold-rolled sheet whose final sheet|seat thickness was 0.23 mm by 200 degreeC warm rolling. Next, in the atmosphere oxidation degree P(H 2 O) / P(H 2 ) = 0.40 oxidative humidity H 2 -N 2 The decarburization annealing which doubles as the primary recrystallization annealing was performed at 840 degreeC for 100 seconds in atmosphere. Then, the surface of the steel plate is coated with MgO as the main body and 10% Cr 2 o 3 After the annealing separation agent was dried, final annealing was performed including secondary recrystallization annealing and purific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com