Vacuum insulation and insulation box using it

A technology of vacuum heat insulation and heat insulation box, which is applied in the direction of protecting pipes, applications, and household appliances through heat insulation, which can solve the problems of low quality of recycled products and insufficient crushing of long-fiber non-woven fabrics, so as to improve the handling ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

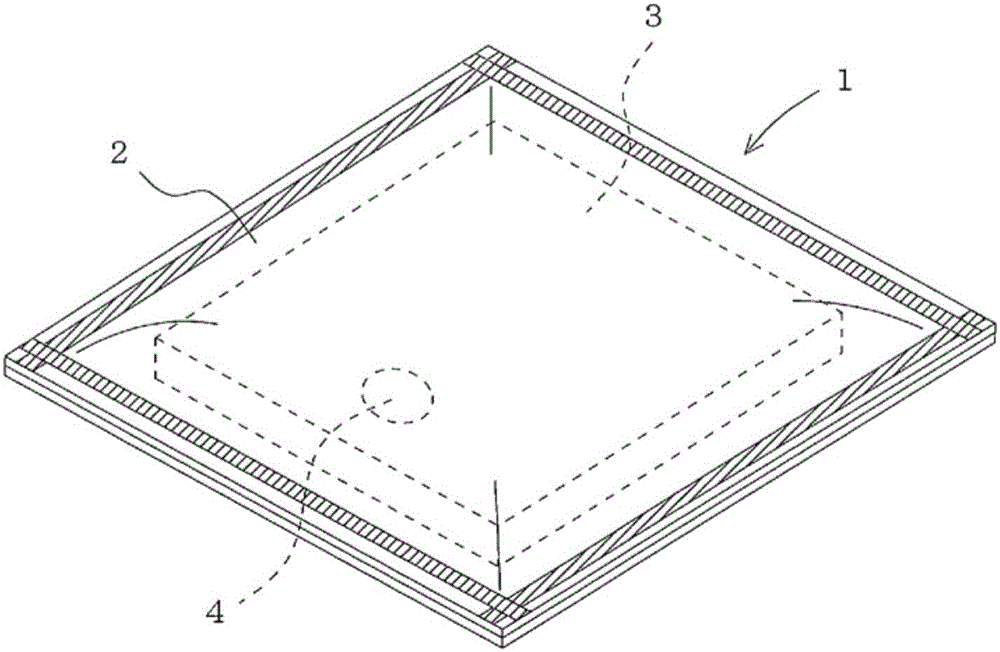

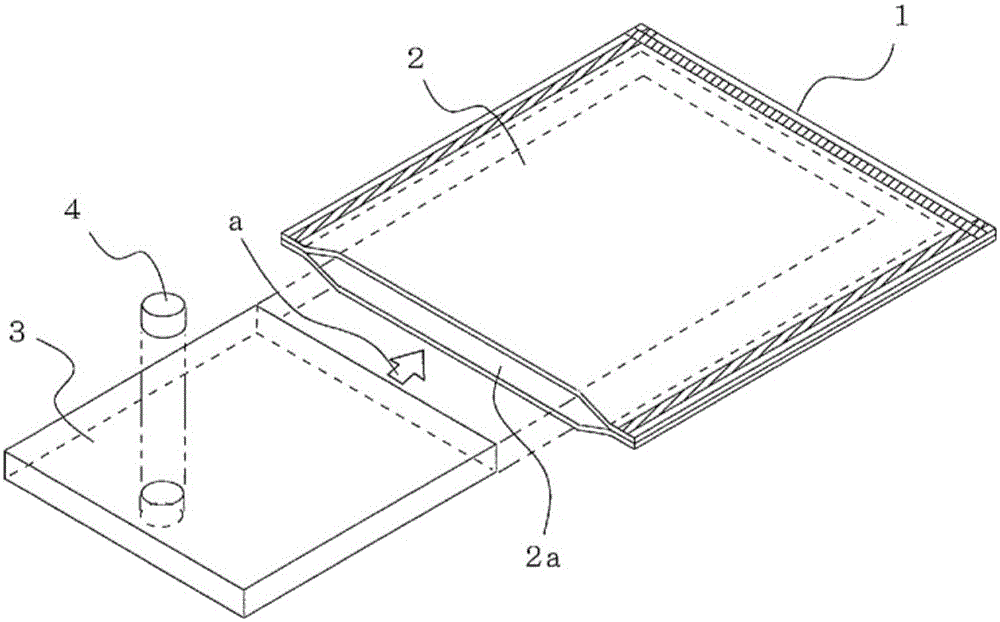

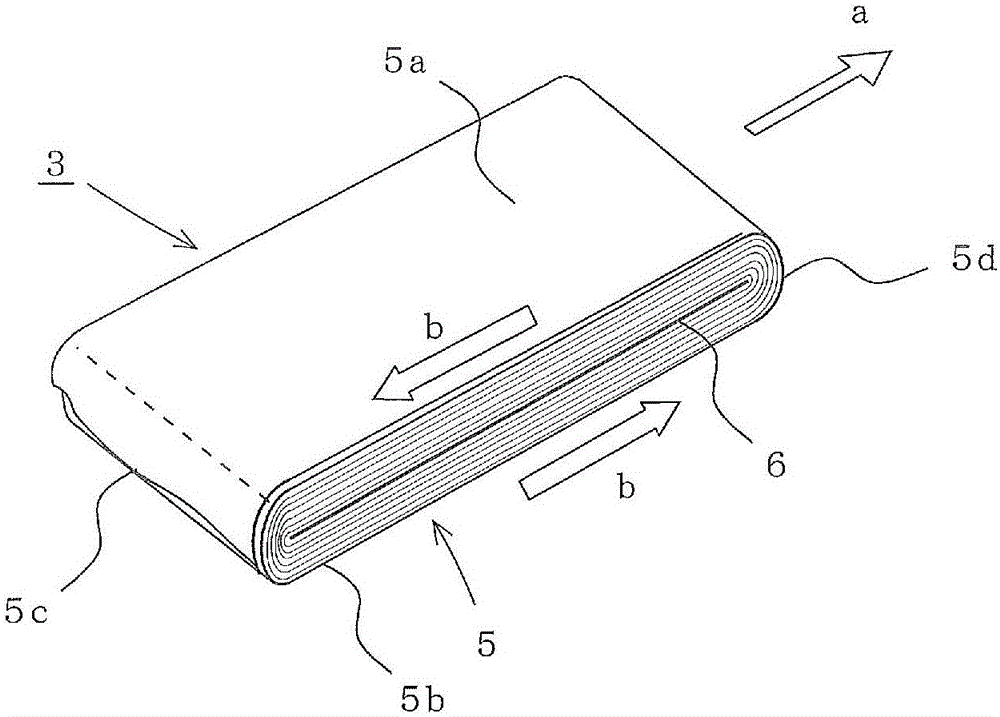

[0049] In explaining the vacuum heat insulating material of Embodiment 1 of the present invention figure 1 , figure 2 Among them, the vacuum heat insulating material 1 is composed of a bag-shaped gas-barrier container 2 having air-blocking properties (hereinafter referred to as an outer cover), a core material 3 and an adsorbent 4 enclosed in the outer cover 2 . The adsorbent 4 is a moisture adsorbent or a gas adsorbent, and adsorbs moisture in the exterior material 2 that causes a decrease in thermal insulation performance.

[0050] Out of the four sides of the outer cover 2, three sides other than the opening 2a are sealed in advance by heat sealing, and the core material 3 is inserted into the outer cover 2 from the opening 2a as shown by arrow a, and the core material 3 is enclosed in the outer cover. 2, the inside of the exterior material 2 is decompressed to a predetermined degree of vacuum, and then the opening 2a is sealed by heat sealing, whereby the vacuum heat ins...

Embodiment 1

[0122] The processed portion 9a of the perforation 9 of the core material 3 of the vacuum heat insulating material 1 of Example 1 is based on Figure 11 In the processed part shown in Specification Example 4, the length of the processed part 9a is 3mm, the length of the non-processed part 9b is 1mm, the processed part 9a is a complete cut through the slit, and the ratio of the processed part of the perforation 9 (the processed part 9a to The ratio of the total length of the processed part 9a and the non-processed part 9b) was 75%.

Embodiment 2

[0123] The processing portion 9a of the perforation 9 of the core material 3 of embodiment 2 is the same specification as the case of embodiment 1, the processing portion 9a is a complete cut, and its length is 4mm, the length of the non-processing portion 9b is 2mm, and the processing portion ratio is 67%. Comparative example 1 has the same specifications, the length of the processed part 9a is 8mm, the length of the non-processed part 9b is 2mm, and the processing ratio is 83%. Both are 3mm, and the processing portion ratio is 50%.

[0124] In the core material 3 of Examples 1 and 2, as shown in Table 1, the lamination workability in the lamination process and the crushability in the recycling center were good.

[0125] On the other hand, as shown in Table 1, the core material 3 of Comparative Example 1 had no problem with the crushability, but the nonwoven fabric 6 was torn during the lamination process. It is considered that this is because the nonwoven fabric 6 cannot w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com