Grain-oriented electromagnetic steel sheet, and steel sheet which can be used as raw material sheet for grain-oriented electromagnetic steel

An electromagnetic steel sheet and directional technology, which is applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve problems such as the inability to fully meet the high performance requirements of directional electromagnetic steel sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

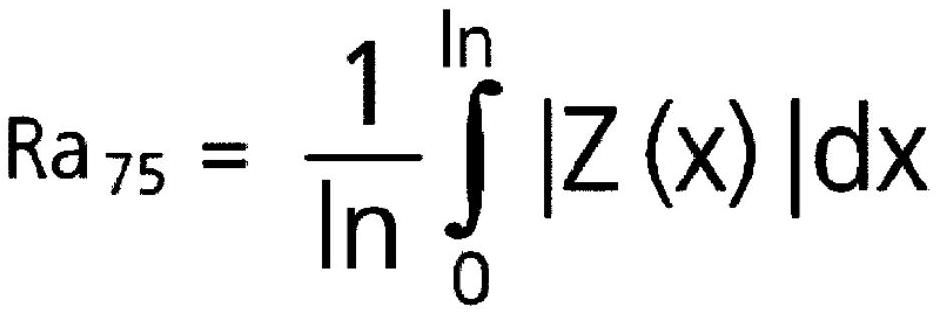

Method used

Image

Examples

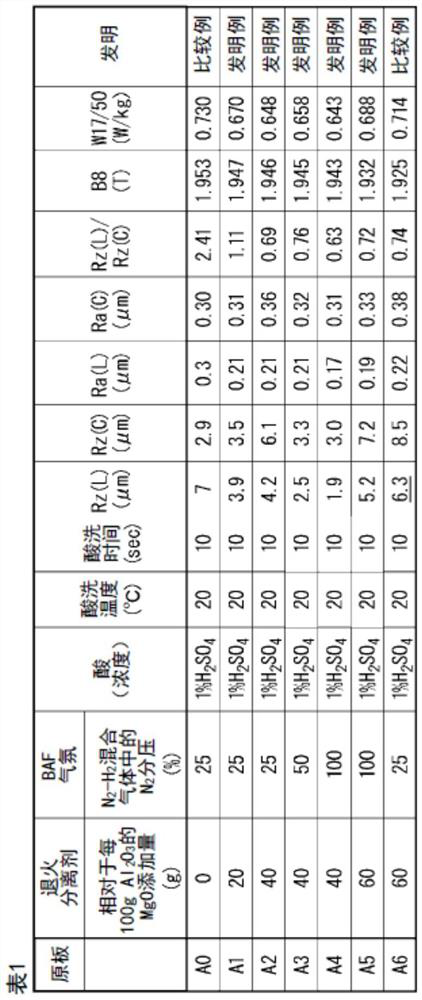

Embodiment 1

[0096] Decarburization annealing is performed on a cold-rolled steel sheet for producing a grain-oriented electrical steel sheet with a thickness of 0.23 mm and Si: 3.2% by mass, and an annealing separator having a composition described in Table 1 is coated on the surface of the decarburization-annealed steel sheet. After the water slurry is dried, it is rolled into a coil shape. Next, the decarburized annealed steel sheet was secondary recrystallized in a dry nitrogen atmosphere, followed by purification annealing (final annealing) at 1200° C. in the BAF atmosphere described in Table 1 to obtain a final-annealed grain-oriented silicon steel sheet.

[0097] These final-annealed steel sheets were subjected to powder-removing pickling treatment under various conditions shown in Table 1. Then, sinter annealing is performed on the pickled steel sheet. Conditions of sintering annealing are as follows. 5g / m2 per side 2 A tensioned insulating coating containing aluminum phosphate ...

Embodiment 2

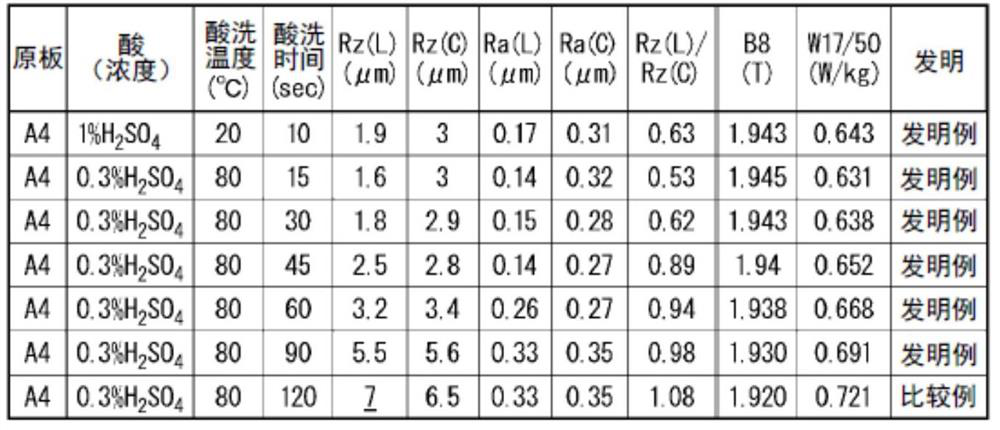

[0113] Grain-oriented electrical steel sheets were produced by the same procedure as in Example 1, under the production conditions in which the pickling time was changed as described in Table 2. In addition, the manufacturing conditions which are not described in Table 2 are the same as the original plate A4 of Table 1. These evaluation results are shown in Table 2.

[0114] Table 2

[0115]

[0116] All grain-oriented electrical steel sheets composed of base steel sheets having RzL within the range of the present invention exhibit good magnetic properties.

[0117] On the other hand, a grain-oriented electrical steel sheet having a surface roughness in the L direction outside the range of the present invention suffers from impaired magnetic properties due to failure to satisfy the production conditions of the present invention. Specifically, the grain-oriented electrical steel sheet whose pickling time was 120 seconds did not satisfy RzL≦6.0, so the magnetic properties w...

Embodiment 3

[0119] By the same procedure as in Example 1, grain-oriented electrical steel sheets were produced under the production conditions of varying pickling temperature and acid concentration as described in Table 3. In addition, the manufacturing conditions which are not described in Table 3 are the same as the original board A3 of Table 1. These evaluation results are shown in Table 3.

[0120] table 3

[0121]

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com